Simon Rawlinson and Matthew Hicks of Davis Langdon weigh up the costs and the risks of treatment solutions

01 / Introduction

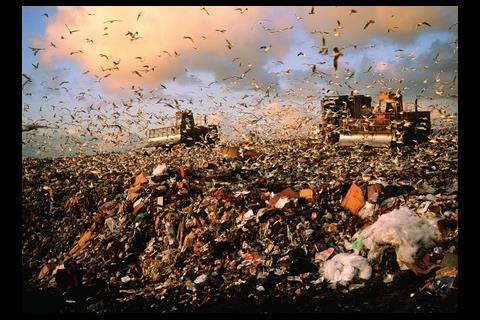

The UK produces over 300 million tonnes of waste a year, 24% of which is derived from household or commercial sources. Historically, most domestic waste has been directed to landfill, and on current disposal rates, the UK has less than 10 years’ supply of landfill left.

Challenging EU targets for the reduction of disposal of domestic waste to landfill have belatedly triggered a PFI market in waste recycling and treatment. Commercial waste producers have also experienced rising costs due to landfill tax and higher gate prices, and are also looking for alternatives to landfill. Waste disposal authorities face fines of £150/tonne if they miss their 2013 and 2020 landfill targets, a policy which is driving waste-related investment worth £9-11bn for the public sector alone between now and 2020. This is equivalent to an extra 500 million tonnes of treatment capacity per year.

Government policy, articulated through the “waste hierarchy” (see diagram below) is to encourage reduction of waste at source and by recycling. However, there are physical and economic limits to recycling, and few waste disposal authorities (WDAs) expect to be in a position to recycle more than 65% of their solid waste stream. Unlike Europe, where incineration is well established, energy from waste is unpopular in the UK. However, with much tighter regulation, improved technology and the growing risk of a UK energy gap, waste’s potential as a resource is now being warmly embraced.

02 / The UK waste industry

The UK waste sector is surprisingly diverse. The waste stream is inevitably varied and requires different treatment and disposal regimes. Within the municipal and commercial waste streams, there are a large number of players. Commercial organisations are responsible for contracting their own waste disposal. In the public sector, there are a host of waste collection and waste disposal authorities, as well as health trusts and education authorities who are responsible for their own waste management. This means schemes may have to accommodate a very varied feedstock. Restrictive planning concessions may also limit the sources of waste a particular scheme can treat – limiting economies of scale and long-term flexibility in the use of a facility.

Based on the waste hierarchy (see diagram, right), much investment has been targeted at minimising the volume of waste requiring disposal. Projects managed by the Waste Resource Action Programme (Wrap) are good examples of the holistic approach adopted in the UK. However, there will continue to be a surplus, and energy from waste as a means of treatment is preferable to the last resort of landfill.

Materials recovery and mechanical and biological treatment processes (MBT) sit above energy from waste in the hierarchy and can produce fuels that can be sold on to energy users. Solid recovered fuel is a product of MBT processes and, in some cases, can be burned without treatment of flue gases.

Energy from waste itself is an umbrella term describing technologies used to extract the chemical energy locked in waste products. Energy from waste techniques include thermal processes such as incineration, as well as a range of thermal or chemical gasification techniques that produce gas and liquid fuels.

The portfolio of energy from waste techniques also includes aspects of pre-treatment required for biological processes such as anaerobic digestion, as well as the treatment of flue gases and other by-products of the conversion process. Technologies used are proprietary and are evolving very quickly in an effort to increase efficiency, deal with a wider range of waste streams and to increase safety. Defra, for example, has recently provided support to the development of advanced thermal techniques (ATT) such as pyrolysis.

Parties involved in energy from waste include WDAs who are tasked with reducing their landfill related to biodegradable municipal waste, commercial waste users who want to reduce disposal costs, and energy users looking for diversified sources. There are 40 waste management PFIs in the UK, many of which involve elements of energy generation, as well as a group of “waste to energy entrepreneurs” investing in capacity to secure long-term management contracts. Grundon and Viridor, for example, developed a speculative plant near Heathrow that has enabled them to secure long-term contracts with WDAs in the M4 corridor. BA and Solena have also teamed up, with a proposal for a hi-tech, plasma arc gasification plant to produce aviation fuel.

Perhaps the most critical stakeholder in UK energy from waste policy is the general public, which is antagonistic to some waste management projects. Opposition is such that more efficient, large schemes with the capacity to treat the waste for a consortium of WDAs are difficult to get through planning.

While very large schemes in excess of 50MW will fall within the remit of the Infrastructure Planning Commission, this applies to few schemes, so planning will continue to be contentious and high risk.

Due to high operating costs, government incentives including landfill tax, Renewable Obligation Certificates (ROCs) and feed-in tariffs will play a critical role in underpinning the economics of schemes.

03 / Potential benefits of energy from waste schemes

Energy from waste projects need to be considered as part of the wider waste management hierarchy, but the UK produces more waste than can be effectively recycled and bulk reduction techniques such as incineration are needed to reduce waste volumes. The main benefits of processes such as incineration are:

- Waste bulk reduction. Incineration will typically reduce waste bulk by 60 to 70%, and some waste products may also be recyclable as aggregates

- Stabilisation of landfill. The bulk of the residual waste stream – bottom ash or vitrified waste – is stable and does not emit methane

- Energy production. Conversion rates of 450-600kWh per tonne are possible through a steam turbine generator

- Energy security. Waste-based energy will reduce UK dependence on imported energy sources

- Long term cost reduction. Incineration will help to mitigate rising costs related to high gate prices and rising landfill tax.

04 / Energy from waste technologies

Outside the UK a range of technologies have been in use for a long time, but very few have a track record with the UK’s mix of waste. With pressure on to have waste treatment plant in place to meet the 2013 landfill deadline, momentum is with incineration. However, looking forward to 2020 targets and long-term PFI deals, more advanced solutions may be adopted.

There are other sets of waste treatment techniques, including MBT and mechanical heat treatment (MHT) that often form part of a PFI. Both include a proportion of materials recovery from the general waste stream and could be used as a pre-treatment for energy from waste. However, they differ in the way the energy value of residual waste is increased and in the quality of fuel produced. Production of solid recovered fuel via MBT or MHT gives WDAs the option to sell on their recyclate without committing to develop a dedicated energy from waste scheme.

Incineration is the most established waste technology in the UK, treating over 4,000,000 tonnes per year. In energy from waste schemes, the heat from the process is used in a steam turbine to generate electricity for the National Grid. Some projects such as Sheffield and Teesside also reuse waste heat through large-scale community CHP systems. Unfortunately, due to the unpopularity of incineration, finding locations next to heat users is very difficult.

The most common incineration technology is moving grate combustion. A potentially more efficient combustion technique, fluidised bed combustion, requires pre-sorting and shredding of the waste feedstock. Relatively few of these plants are in operation. Although well established, moving grate technology has significant complexities associated with the optimisation of combustion, reuse of energy and the need to meet extremely stringent flue gas standards. Flue gas cleaning can add between 30% and 60% to the capital cost of the equipment.

ATT processes use heat and pressure to extract gases and oils from waste materials. Gasification uses a temperature of about 750ÞC and releases useable hydrogen and methane as well as carbon monoxide.

Pyrolysis takes place at a lower temperature, 300-800ÞC, under pressure and in the absence of oxygen. The process is designed to extract a greater calorific value than gasification and will produce a combination of gases, oils and waxes. The gases and oils can potentially be used as a bio-fuel, although currently the only use is for electricity generation using a CHP.

Unlike incineration, both gasification and pyrolysis require pre-processing of waste material. They also produce flue gases that require treatment.

Another emerging technology is plasma arc gasification. This involves passing waste into a kiln at 4,000-7,000ÞC. Gases released are collected, and any waste products are immobilised in a vitrified mass that can be safely disposed of. Plasma arc gasification promises much, but with few “reference” plants to confirm performance, adoption in Europe will be gradual.

Anaerobic digestion is a biological process for the organic portion of municipal solid waste. Advantages include scalability and low running costs. Implementation issues include waste preprocessing, and disposal of the non-organic waste and the residual “digestate”. Defra is promoting development of anaerobic digestion capability in the UK and more than 10 large-scale schemes are in development. The long-term vision is that bio-fuels from anaerobic digestion and ATT will be used as part of the natural gas or liquid fuel supply.

05 / Cost and value drivers

Energy from waste projects are typically procured on a build-own-operate basis, with operational and commercial risks being taken by a waste consortium. The economics of energy from waste schemes are subject to many sources of risk and uncertainty, so although a scheme will usually be set up with a guaranteed feedstock source, overall viability will be subject to a wide range of pricing, deliverability and performance risks. Combined with the requirement to secure very large values of private finance, this level of risk exposure tends to favour the use of well established technologies and solution providers.

The main variables affecting energy from waste viability are as follows:

End user requirements - Project sponsors such as WDAs have been in competition for scarce waste management expertise and private finance. In practice, larger WDAs are in a stronger position to determine preferred solutions than smaller authorities who have in some cases struggled to attract operator interest. Other areas where end-user requirements might affect the project design include the consistency of the waste feedstock they can provide. Projects serving a consortium of WDAs will need to be designed to deal with a less consistent waste stream, with a consequent impact on efficiency.

Income - The main sources of income are the gate price for the waste stream and the sale price of energy and by-products such as aggregates. The waste gate price, currently about £60 to £90/tonne, has increased substantially with the support of landfill tax and typically contributes 70% of income. Certainty with regards to the continuation of the landfill tax accelerator is an important consideration for operators and investors.

Depending on the technologies adopted, there may be additional income streams related to exported heat energy as well as income from incentives such as ROCs.

Costs - Energy from waste schemes need substantial investment in pre-treatment and grid connection infrastructure, as well as land and main generator plant. Operating costs are also substantial, particularly those related to safe operation. According to Wrap, total costs of disposal via energy from waste range from £65 to £136/tonne.

In terms of operating costs, the main areas of risk involve throughput, energy prices, the operating and maintenance regime and the costs of disposal of waste products. Replacement cost of plant also has to be factored into the model. The implication of lower than expected throughput is increased unit costs. Lower waste conversion rates will increase cost related to landfill tax liabilities.

Additional cost and value drivers

Most value drivers associated with energy from waste are related to scale of operation, which is difficult to optimise due to planning constraint. Many of the risks relate to the effective operation

of plant, which makes innovation particularly difficult to deliver – especially in smaller schemes that have a limited range of treatment processes. There are a number of high-profile projects where timescales and quality standards have not been met, and where testing and commissioning has taken significantly longer than anticipated.

06 / Additional cost and value drivers

VALUE

- Mitigation of long-term costs to the WDA Energy from waste projects eliminate risks of exposure to penalties from the Landfill Allowance Trading Scheme relating to landfill disposal in excess of allowances.

- Risk transfer through procurement Turnkey procurement via PFI or a treatment contract enables clients to secure large-scale investment and to outsource project delivery and operational risks.

- Minimisation of social impacts including vehicle movements, where this can be achieved using existing infrastructure such as rail.

- Economies of scale Energy from waste schemes are most cost effective with a throughput in excess of 350,000 tonnes a year. For larger projects it is claimed that doubling the throughput of a scheme only results in a cost increase of 50%. Other benefits of scale include reduced land-take and higher operational efficiencies.

- Recovery of value from the waste stream including heat energy and recyclates such as aggregate or solid waste fuel.

- Quality of the business case, including good quality information, use of well-established technologies and extensive scenario modelling.

- Accurate estimation of the quality and volume of the waste stream, so that plant operates effectively.

- Diversification of waste management processes to include waste reduction and recovery. Materials recovery and composting are cheaper and more environmentally desirable than combustion. Larger projects that enable a range of techniques to be cost effectively included in the treatment mix should deliver optimum outcomes.

- Diversification of sources of waste – dealing with commercial and municipal waste streams together improves economies of scale and certainty of waste supply.

- Continuing incentivisation of waste reduction and recovery strategies.

RISK

- Certainty of availability End users need assurance that the proposed plant will deliver the expected waste throughput and waste bulk reduction within strict emissions levels and timescales.

- Certainty of delivery Where the project delivers useable output such as a syngas or solid recovered fuel, assurance of product quality is critical.

- Project delivery Risks include integration and co-ordination of complex and distinct technologies for pre-treatment, combustion, flue gas treatment and the grid connection. Site constraints to the plan or building height may limit the proprietary technologies that can be used in a particular location.

- Planning risks Planning challenges include health concerns, traffic movement and the visual impact of a development that can include a 90m high stack. Planning consents may involve restrictions on operations such as limits on where waste can be sourced from. Other risks include delays in the planning process for overhead power line connections.

- Project delivery Guarantees that transfer risk related to the availability and quality of feedstock and the availability and performance of the technology will also improve viability – so long as the warranties are enforceable.

- Co-ordination of programme delivery Projects that involve a number of technologically distinct but closely related components need effective programme management.

- Technology risk associated with complex processes Each new feature incorporated to reduce emissions or increase energy recovery contributes to this risk.

- Supply and demand risk Reference projects with an extended track record of operation with a UK waste stream are important business case evidence for both end-user clients and funders.

- Viability risk related to the long-term value of incentives such as landfill tax and ROCs.

- Supply risk associated with the volume, quality and consistency of the waste stream.

- Demand risk related to markets for recyclates such as solid recovered fuel as well as waste heat, and the prices that can be obtained for these products.

- Political risk for end users of commitment to energy from waste if incentive to recycle is reduced.

In summary, the risk exposure on energy to waste projects is relatively high – particularly for emerging technologies. Turnkey contracts are an important mechanism to enable these complex interrelated risks to be packaged in such a way as the main objective of optimising the use of waste as a resource is met. This concentration of risk will inevitably result in a risk premium which can be mitigated to an extent by giving suppliers freedom over the application of technologies.

07 / Procurement

Delivery of energy from waste projects is an extended process, typically taking seven to 10 years. In the current market, there are many WDAs seeking to secure relatively scarce technological and project delivery resources, and as a result, the packaging of the project will be critical in attracting interest from bidders and from PFI financiers.

Some major issues in procurement deal with attracting the most appropriate bidders in the first place, obtaining finance and devising the most cost effective project delivery mechanism in order to integrate the major elements of technology.

Supplier selection in the public sector presently involves a costly and complex competitive dialogue process. The advantage to both the promoter and the provider is that the competitive dialogue process enables a range of technologically different solutions to be considered as part of the bidding process. Unfortunately this increases the costs of all parties. Recently, smaller authorities have had difficulties in attracting compliant bids.

Private finance is more costly in the waste sector than some other PFI streams because of the range of risks involved. The costs of large “back-end” projects, such as incinerators, are such that since the loan syndication market collapsed in 2007, funding has been more difficult to arrange through “clubs” of lending institutions. The Manchester waste PFI, worth over £1bn, received far higher public sector funding through the European Investment Bank and the Treasury infrastructure finance unit, than had originally been anticipated.

Another key issue concerns the management of construction delivery risk within the special purpose vehicle. SPV projects are typically delivered to the service operator via an engineering, procurement and construction (EPC) contract. The operator’s risk can be minimised by wrapping all aspects of the capital works – pre-treatment, main plant and grid connection infrastructure – into a single EPC deal. However, these arrangements add significantly to costs related to fees, management resource and risk premium. An “unwrapped” approach, where the SPV takes a more direct role in managing risk, may increase returns and reduce overall cost to the public sector, but could be more difficult to finance.

The final, critical aspect of procurement of waste treatment projects is testing and commissioning, which in the UK requires extended evidence of effective operation before full certification.

08 / Cost model

The cost model provides outline costs of the building facilities associated with a 600,000 tonne a year combustion plant based on a three-line moving grate technology. The analysis also provides indicative costs of the combustion system and the grid connection. Details of the scope of external works are included as these are a critical element of the operation of the facility.

Site preparation costs, client-side professional fees and VAT are excluded.

Downloads

02 / The UK waste industry

Image, Size 0 kb08 A / cost breakdown

Image, Size 0 kb

Postscript

Acknowledgements

We would like to thank Jon Dedman, Steve Waltho and Peter Browne of Davis Langdon’s energy team for their contribution to this article.

No comments yet