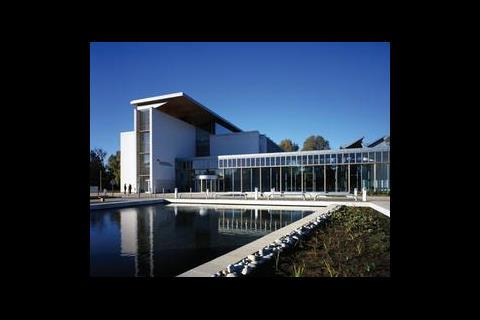

When the University of Gloucestershire’s new campus opened three years ago, there were high hopes for its low-energy design. Jason Palmer visited the Oxstalls development to find out how it has lived up the hype

When the University of Gloucestershire’s

Oxstalls campus opened its doors in 2002, it was to high expectations. A flagship development for one of the largest sports and exercise educators in the country, it was hoped that the new campus would attract many new students. Not only that, it also presented a very bold statement of low energy design – as well as the striking building-integrated photovoltaics on the roof and the more discreet, but arguably as effective, Termodeck ventilation inside, it went way beyond the demands of the Part L Building Regulations of the time.

Three years later, the campus has pulled in so many students that it is being extended, so it has certainly earned its stripes in that respect. The only question left is whether the buildings actually live up to their low-energy aspirations.

The project began in earnest following an OJEU competition, when the University appointed architects Feilden Clegg Bradley and engineers WSP. Although the brief evolved during the design, the client wanted the buildings to demonstrate a low-energy approach from the start – not least because the vice chancellor felt strongly about the environment. The University has also certified its environmental management system to ISO 14001, a sign that there is management backing for environmental initiatives.

The development comprises two buildings – the Sports Science Building and the Learning Centre – both quite different in their form and services strategies. The 2860 m2 Sports Science Building incorporates a sports hall, teaching areas, lab space, cafeteria and offices for teaching staff. It has a sawtooth roof with photovoltaics on the south-facing pitches and vertical rooflights on the north-facing pitches.

The 2700 m2 Learning Centre, meanwhile, features a three-floor library, offices and classrooms. The architecture is more restrained, and the south facade could easily be mistaken for modern offices, with its plush solar shading from brise soleil.

The two buildings are joined by a glazed walkway, called the “Link”, which accommodates the entrance foyer. Early design work had this as an open walkway, but it evolved during design into a closed space with a little tempering.

Unfortunately, the scheme’s evolution continued post-completion and handover for, in spite of its poor insulation and single glazing, the attractions of this large, central space mean it is now used for exhibitions and meetings, and has “temporary” heating from large propane warehouse heaters in winter.

Is it comfortable?

The ventilation strategies underlying the Sports Science Building and the Learning Centre are quite different. While the Sports Science Building is mostly natural ventilated, the Learning Centre has mechanical ventilation throughout.

The Sports Science Building’s sports hall has motorised louvres, which close when internal temperature drops below a set point. Offices and teaching rooms here have opening windows and only the refectory, toilets and environmental chamber have mechanical ventilation.

As for heating, four condensing boilers in the plant room serve both buildings via variable speed pumps. Heat is delivered to the Sports Science Building itself through conventional radiators with TRVs and a little trench heating along a few fully glazed areas, such as the cafeteria. It has to be said that when I visited, some treated spaces in the building were rather chilly (around 18°C).

In the Learning Centre, two air handling units at roof level beside the central atrium drive 100% fresh air into the building during the hours it is occupied. When the building is unoccupied, the ventilation can switch to 100% recirculation or 100% fresh air (depending on season), with a single fan used to move air around, pre-cooling or pre-warming the termodeck slabs in preparation for the next day.

Air is pumped through the Centre’s Termodeck hollow core slabs and then into occupied areas through a conventional displacement system running under raised floors (see diagram, right). Stale air leaves via the atrium, where it returns to the AHU for heat recovery in winter and is finally ejected into the Link through a builder’s work duct, to help temper this space. This duct has not proved successful in transferring warm air, which means the Link currently falls below the (modest) design temperature of 16°C in winter.

The hot water circuit continues under the Link to supply heating coils in the AHUs and radiators for space heating. Staff expressed concerns about winter temperatures, especially in the library reception, where cold drafts enter from the Link whenever a security window is opened.

In the summer, the Learning Centre’s slabs are cooled overnight, and the high thermal mass helps keep daytime temperatures low without resorting to mechanical cooling. The unusual feature here is that the concrete slabs are interspersed with timber cladding and acoustic insulation to reduce noise – a priority in a library.

There is a little mechanical cooling for high-density spaces (a total of 100 kW installed in the Termodeck part of the building), which defaults to off as it is intended only for emergency use and has to be switched on manually. These small, direct expansion systems conflict with the general ethos of the design, but the university was fearful of summer temperatures reaching more than 26°C, which students could try to use to excuse poor exam performance. The approach proved very successful, and monitoring has shown the cooling is used very infrequently.

The Learning Centre was pressure-tested three times, and ultimately achieved 10 m3/h/m2 of facade and floor at 50 Pa. The pressure testing exceeded Part L requirements, but was pushed by Termodeck. It was disappointing that the contractors couldn’t improve airtightness further, but the contract wasn’t set up with airtightness in mind.

Moreover, it is likely that the untested Sports Science Building and Link are leakier than the Learning Centre, which does nothing to improve energy performance or winter comfort.

Is it low-energy?

The engineers and architect took many measures to keep energy consumption to a minimum: good insulation (a minimum of 150 mm Rockwool in walls and roof) and glazing; displacement ventilation with low air velocities; daylighting where possible; incorporating high frequency lighting and high efficiency valves. However, WSP’s Graeme Grainger admits candidly that “the ambition hasn’t quite been reached”.

Despite the lengths that designers went to in order to allow daylight into the sports hall, it seems that the electric lights in here are usually left on. Fortunately, there are two settings for the lights (one of which is for county cricket, providing a whacking 800 lux, and another for normal use, providing about 400 lux), and they are left on at the lower setting.

A DTI grant, provided under the Large-Scale Building-Integrated Photovoltaics in Buildings programme, enabled the University to include renewable power in the scheme. The grant covered 40% of the cost of the PV roof, and matching this with a 60% grant from the EU’s ENERGIE programme made this symbol of environmental commitment economically viable.

The Learning Centre was included in the European-funded EUBART project, which paid for excellent metering and did post-occupancy evaluation in 2003-2004*. The study found that gas consumption was 111 kWh/m2/y (double the design target for gas), and electricity consumption was 108 kWh/m2/y.

Overall, it still matched the ECON 19 good practice target for a Type 3 (air-conditioned) office, but had much higher energy consumption than a similar low-energy library in Sweden.

The EUBART project attributed the high gas figures to a leaky envelope and controls in need of “fine tuning”. The bottom line was that the University’s enthusiasm for low-energy building, expressed during procurement, hadn’t translated into the thorough commissioning, “sea-trials” and gentle ongoing monitoring required to keep this relatively complex low-energy building running as it should.

In hindsight, Grainger thinks the original targets may have been too aggressive because they didn’t anticipate the high intensity of computer use in the library (there’s a PC on every desk). WSP and the University have identified several areas where there is scope for saving energy.

The bigger picture

There is no on-site energy manager for the campus, and on my visit, I had the impression that energy management was reduced to fire-fighting: the propane-burning warehouse heaters in the Link had to be ventilated, so the opening glass louvres were set in summer positions to get rid of burnt propane fumes.

Feilden Clegg Bradley’s Matt Somerville thinks part of the problem is that the finishes chosen sent the wrong message: carpeting in the Link led occupants to think they should expect interior comfort conditions there. Originally, it was conceived as a semi-external space and had been designed with a stone floor, but this was stripped out as part of value engineering. If he’s right, the extra cost of flooring would have been quickly repaid in propane savings.

The University’s technical services manager, David Evans, who looks after Oxstalls Campus from a distance, explains that the long occupation hours are one of the reasons it doesn’t meet the design targets for energy: “The core hours are 8 am to 8 pm, but we often have to extend hours at night and at weekends, which means energy consumption is higher than other educational buildings. It’s not easy to keep energy-use down when occupied hours change all the time.”

As the EUBART project points out, it is also difficult for staff to justify spending much time on new, relatively efficient buildings when other parts of their estate require more attention and provide more obvious opportunities for saving energy. Moreover, the team now responsible for managing the buildings is different to the Estates team who procured the building and understand the services strategy.

Nevertheless, compared to the Econ 54 targets1 for higher and further education buildings (which admittedly aren’t very ambitious), Oxstalls fares better than you might expect (see figure 1, above). Based on bills data from 2004–2005, corrected to national degree days, the Learning Centre beats the target for gas by about 7%. But electricity consumption suggests room for improvement, at two-and-a-half times the target – partly because of the number of computers, long fan operating times and the absence of occupancy sensors on lighting.

The Sports Science Building fares better. Electricity is almost exactly the same as the benchmark figure for this sort of building (despite the energy-intensive lighting in the sports hall, the high demand from the labs, and occasional use of electric heaters), but gas is 50% lower than the benchmark. On top of this, the PV system contributes 40.8 MWh a year, which translates to 14.3 kWh/m2, or 9% of the building’s electricity use.

The buildings are less impressive if you focus on CO2 because electricity performance is weaker than gas, and electricity use implies more than double the CO2 emissions of gas. This analysis also excludes the glazed Link – clearly using an awful lot of propane in winter – for which no data was available.

Moreover, if you compare these figures to the 1993 vintage Elizabeth Fry Building at UEA – also incorporating Termodeck and often lauded as the best higher education building for energy use – Oxstalls looks rather disappointing. PV’s contribution to the figures fails to offset a much greater dependence on gas and electricity.

The next phase

There are plans under way to extend both buildings, albeit more conservatively than in the first phase of the scheme: the 600 m2 Sports Science Building scheme will be a simple box with no sawtooth roof, daylighting or PV. As Matt Somerville explains, there’s no funding for PVs now, and it couldn’t be justified on economic grounds.

It is revealing that the 2500 m2 Learning Centre extension, which is in detailed design now, will not have Termodeck slabs. Instead it will have a reinforced concrete frame and use mixed mode services: opening windows wedded to displacement ventilation.

The University has requested a separate study to explore how other significant low-energy measures can be incorporated into these new projects, including an undercroft with some form of thermal labyrinth.

Partly for cost reasons, the Learning Centre extension will not have the elaborate brise soleil of phase one, but will include solar control glass to reduce heat gains. This is expected to result in only slightly higher solar gains than the existing system, but will bring with it significant cost and programme savings.

Overall, both schemes are much simpler than the original buildings, despite being designed by the same architect and engineers. Project manager Bernley Wilson Fish was unwilling to comment, but this appears to be more to do with cost and programme considerations than anything to do with energy performance.

So, have the original buildings achieved what the designers set out to do? Their appearance and layout has been well-received, they are flexible, and they seem to fulfil the University’s teaching objectives for the campus. They were also handed over on time, which was critical to accommodate a new intake of students.

The University is aware of the problems with comfort conditions in some areas and has tackled them. Energy is not its first priority (nor, arguably, should it be) and bearing this in mind, its performance looks remarkably good. n

Oxstalls Campus, Gloucester: the facts and figures

Client University of Gloucestershire

Project manager Burnley Wilson Fish

Architect Feilden Clegg Bradley

M&E consultant WSP

Structural engineer Whitby Bird

QS Burnley Wilson Fish

Main contractor HBG

M&E contractor MJN Colston

PV installer PV Systems

Engineering data

Gross floor area (gfa) 2720 m2 (Learning Centre), 3000m2 (Sports Science Building)

Net usable area 2448 m2 (LC), 2860 m2 (SSB)

Occupancy Approximately 1000 students and 30

full-time staff during term time. Outside university

terms, it is increasingly used for conferences.

Contract details:

Tender system Competition

Form of contract JCT 98

External design conditions:

Winter -4°C/Sat

Summer (non a/c) 26°C db 20°C wb

Internal design conditions

Winter 20°C min

Summer (non a/c) 25°C

Circulation & toilets 20°C

U values (W/m2k):

Walls 0.25

Floor 0.32

Roof 0.2

Glazing & rooflights 1.9, LC north façade 1.6

Noise levels

Offices/classrooms 35 NR

Toilet and circulation 40 NR

Target energy use (gfa)

Total 110 kWhr/m2/y (Learning Centre)

Typical occupied hours 8am–8pm

Diversity (hours/week)

Fabric leakage 10 m3 per m2 of envelope @ 50 Pa

BREEAM No

Loads

Installed heating load 640 kW

Calculated cooling load 143 kW

Installed cooling load 143 kW

Ventilation

Fresh air 100% occupied hours (10 litres/s/per person), 100% recirculation when unoccupied

Primary air volumes

Total fan power 1.5 W/l/s primary air (Learning Centre)

One AHU at 3.8 m3/s

One AHU at 3.2 m3/s

Refrigerant

DX Units R407C

Lighting, lux levels

Sports hall 400/800 lux

Learning Centre 400 lux

Costs

Total cost £14m (including residences)

Building services total £4m

Solar on the sawtooth

Robert Cohen, who monitored the buildings for William Bordass Associates as part of the EUBART project, said installing the photovoltaics was straightforward – although, because of the complexities of funding coming from different sources, the sawtooth roof had to be completed as a weather-proof entity before the PV was laid over the top.

It is connected to the National Grid to export electricity when the University does not need the energy. The 64 kWpeak photovoltaic array is made up of 368 polycrystalline modules. Each of the 23 south-facing pitches carries a row of 16 modules with an inverter at one end.

Principal architect Peter Clegg was initially concerned about the appearance of the PV modules because the colour of individual panels was a little variable. In fact, the PV is almost invisible to passers-by, and if the installer had been able to sort the panels to avoid placing contrasting colours side-by-side, this may have eliminated the problem altogether.

Annual energy generation from August 2004 to July 2005 was 40.8 MWh, which translates to 14 kWh/m2 for the Sports Science Building –

a worthwhile contribution. Steven Firth from

De Montfort, who is monitoring the PV for DTI, said the yield is pretty much what you’d expect, although a little lower than the installer’s original estimate of 51 MWh/y.

What do occupants think?

A straw poll of students and staff on a cold day in December found that most people viewed lighting and noise in the buildings positively. However, they were less impressed by summer temperatures and air quality, and generally dissatisfied with winter temperatures – especially in the Link and near the entrance to the Learning Centre.

Lesley (student): “I like the spacious and airy environment, but the Link is freezing sometimes. It’s a shame there’s no gym too – there should have been for a sports college.”

Pat (information assistant): “The building looks wonderful, but in winter, the ground floor of the Learning Centre is unacceptably cold to work in. Every time the door opens there’s a blast of cold air.”

Charlotte (student): “The Learning Centre can be noisy and some rooms are cold during winter.”

Alicia (student): “The Link and canteen are very cold in winter, and it’s also cold near the windows in the Learning Centre. The physiology labs are too hot and stuffy in summer.”

Neil (student): “I like the buildings – they were one of the main things that attracted me here – but it can be hot in summer and cold in winter.”

Downloads

Page-28.gif

Other, Size 0 kbFigure 1

Other, Size 0 kbSection through the Learning Centre showing the Termodeck ventilation system

Other, Size 0 kb

Source

Building Sustainable Design

Postscript

Dr Jason Palmer is a director of Cambridge Architectural Research *BRECSU, ‘ECON 54: Energy efficiency in further and higher education’.

No comments yet