If you can’t stand the heat you need a more energy efficient kitchen. That’s what BDP’s environmental engineering team delivered, times eight, for a catering training facility in Waterford. Will Jones checks out the menu.

Commercial kitchens are heavy energy users, says Chris Croly, environmental engineering director at BDP in Ireland. “They use lots of power for cooking; they produce large heat gains; and, as a consequence, require a lot of energy for mechanical cooling.” Not the ideal ingredients for a low-energy design, then, and Waterford Institute of Technology has not one but eight kitchens for training chefs.

Croly and colleagues nonetheless succeeded in creating a passive design for the institute’s tourism and leisure studies building, completed last year. Working with the architect A&D Wejchert & Partners, they built upon the concepts developed in the nurse education building on the same site in southeast Ireland. It won Best Sustainable Building at the Irish Architecture Awards. The £20m tourism and leisure building had considerably more complex environmental demands, however, because it includes the heavily equipped training college for chefs.

Low-Energy Kitchen Design

BDP worked with the catering consultant, Gary Moss, to create a low-energy model for today’s commercial kitchen plus a “kitchen of the future” that significantly reduces the energy required in the high-temperature environment (see below).

The eight student kitchens are on the ground floor, with classrooms and offices on the two floors above. While the kitchen of the future has advanced energy-saving appliances, the more conventional units – a pastry kitchen (100m2), larder kitchen (110m2), two production kitchens and three training kitchens (114m2) – still posed a challenge in minimisation of energy use.

Windows and rooflights reduce artificial lighting requirements and hot water is provided by dedicated condensing heaters. Most important, however, was the space cooling strategy devised by BDP. Instead of using air-conditioning, with mechanically cooled air supplied and extracted at high level, the college kitchens have a forced air displacement system with a low-level supply.

“Conventional high-level supply and extract systems are very inefficient in kitchens,” says Croly. “The heat gains near the ceiling are immense and so any cool air introduced here warms almost before it reaches the zone occupied by the chefs. To counteract this, the air is cooled to even lower temperatures, so using more energy.”

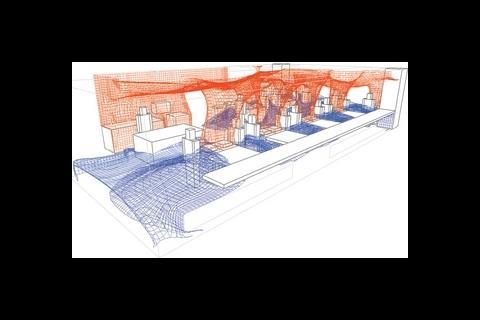

BDP used 3D computational fluid dynamics modelling techniques to understand the heat distribution within the kitchen spaces, with the results revealing the high temperatures at ceiling level and plumes of heat. This enabled the team to design a displacement ventilation system that supplies cool air via a low-level plenum in units at the room perimeter. (The plenum is also a conduit for water and drainage services.) Hot air is extracted at high level via the ventilated ceiling.

“The kitchens have staged ventilation,” explains Croly. “When the temperature hits a certain level the automatic windows open. Then, as it gets hotter, the displacement system kicks in and variable speed drives slowly ramp it up as required. No refrigeration is used and the students work in a pool of cool air, while the heat rises above the occupied space to be dispersed though the ceiling.”

In winter, the air supply is switched automatically to overhead if the displacement system control records an outdoor temperature of less than 8C, taking advantage of the passive heating of air in the upper plenum and at high level in the kitchen itself. Warmed air is pumped into the kitchen through inlet grilles in the ventilated ceiling without the requirement for heat exchangers.

Passive solutions

The rest of the building follows the low-energy model set by the kitchens. The large atrium and rooflights promote natural light throughout. The north elevation features a lot of glazing while on the south side windows are set into reveals in the facade. These reveals, a product of the deep walls that carry the air extract from the kitchens to roof level, help to shade the glazed elements. The glazing also has integral light shelves, which reflect high sunlight away from the building, bounce mid-level light onto ceilings and allow in low-level sunlight.

The atrium is used as a central stack, drawing free cooling through the spaces during the day and night, for storage in the exposed concrete mass. The building achieved an air tightness result of just over 5m3/m2/hr at a test pressure of 50Pa and its overall energy consumption is forecast to be less than half that of a similar building constructed to good practice standards.

Control of the internal environment is monitored remotely by BDP via an internet link. “We did the same on the nurses’ building and it is of enormous benefit,” says Croly. “We are monitoring and tuning the BMS to achieve the optimum operating conditions for the building and its occupants. Over the next year or so we will step back and allow the college to manage the environmental conditions and then assess how things are running after a couple of years. It is after-service care for the client but it is also valuable information for us to take forward to future designs.”

Kitchen of the future

One of the kitchens at Waterford Institute of Technology is fitted with equipment that will help teach the chefs of tomorrow about sustainable cooking.

“We got the catering consultant to tell us how the chefs use each main piece of equipment,” says BDP’s Chris Croly. “The answers were startling. Chefs like gas hobs rather than electric, but up to 60% of the energy emitted is lost to the atmosphere. And chefs don’t tend to switch them off between uses, so a gas hob can burn for hours.”

BDP’s answer was the induction hob. “They are the most important element of the kitchen of the future as hobs are responsible for most of the heat generation in a kitchen,” says Croly. Replacing conventional hobs with them reduces space heat gains by about 50%.

“Kitchens are often unbearably hot,” he says. “Heat gain can be handled with energy-intensive air-conditioning, but even that cannot cope with radiant heat from equipment. The induction cooker releases considerably less radiant heat than traditional ones.”

The induction hob is not actually heated: an electro-magnet below it generates an eddy current in the cooking pan walls, which heats the food. This means induction hobs generate less waste heat so space conditioning loads are smaller, and they turn off automatically when the pan is removed.

Infrared grills are used instead of the traditional gas-powered overhead versions. Gas salamander grills are usually left on permanently and a lot of heat is wasted through convection, as the connective heat rises away from the food. An infrared salamander produces only radiant heat which is directed at the food, so the food receives all of the generated energy.

Combi-ovens have been installed, which, while not great energy savers, are versatile as they contain a steam injector that can control accurately the relative humidity in the oven during cooking. The students also use planch plates – solid plate, multi-purpose cookers not normally found in training kitchens.

Details

Project architect A&D Wejchert & Partners

Building services engineer Building Design Partnership

Structural engineer Michael Punch & Partners

Quantity surveyor Healy Kelly Turner & Townsend

Catering consultant GM Associates

Main contractor Brian McCarthy Contractors

Mechanical subcontractor Mercury Engineering

Electrical subcontractor JRE Electrical

Controls specialist McCool Controls

Downloads

Ground-floor plan showing kitchens

Other, Size 0 kb

Source

Building Sustainable Design

No comments yet