BDP was determined to outshine Category Rated luminaires for its new schools project. It succeeded with a unique design including integrated daylight control

Suspended above the desk in Martin Lupton's Clerkenwell office is a light fitting with a difference. It's the final prototype of a design he's spent the past three years painstakingly developing and which, when production begins in earnest, could radically change the way classrooms throughout the country are lit.

Lupton has been working towards this goal since BDP won the contract to design two City Academy schools in Bristol. As head of BDP's lighting division he was involved at the concept stage. Out of the two schools, Fairfield Academy stood out due to the large number of hearing impaired students who would be attending.

"When we started looking at the project we began to think about the quality of the artificial lighting that was needed," says Lupton. "Hearing impaired people hear with their eyes, they need to see lip movements and facial expression clearly and we knew the quality of light had to be very good on the vertical surfaces."

The darkness

The problem was coming up with a suitable fitting. When Lupton began his search he noticed classrooms - historically lit by recessed prismatic luminaires - had not escaped the spread of the Category Rated linear louvred luminaire. Many schools suffered from the same problems as today's offices: poor vertical illumination, harsh shadows and dark upper walls and ceilings.

The obvious answer was to use fittings that provide an element of both direct and indirect light. Although these have gone a long way to addressing the problems of the old Category Rated luminaires, they tend to be inherently more expensive and beyond the budget for most school builds.

The search for a modern equivalent of the old prismatic fitting did turn up two possibilities. These were installed in BDP's offices, where Lupton and his colleagues sat and worked. "We really wanted to immerse ourselves in them; we didn't want to recommend anything we hadn't tried," he says. Both, however, had drawbacks: too much glare, lack of universal aesthetic appeal and the difficulty of incorporating integrated daylight control - one of the design team's objectives.

It was about this time that BDP won the contract to design a further four City Academies. In addition to the two in Bristol this meant the sort of quantity of fittings that could justify manufacturing a special one-off unit.

BDP drew up a brief. The luminaire needed to provide a light distribution that could be delivered into the space in a controlled way, and achieve the targets of 300 lux on the horizontal plane for normal teaching spaces and 500 lux for science/art rooms, both with a vertical illuminance of 200 lux. It would also need to be possible for the lamp image to be redirected at critical angles to reduce glare and for a limited amount of light to be emitted upwards to light the ceiling.

The type of lamp was considered carefully. Reduction of glare was critical and for this reason it was decided to focus on a T8 rather than a T5 lamp. Operating on dimmable HF gear, the T8 58 W lamp has a high luminous efficacy, very close to that of a T5. It was also felt that a luminaire designed around a T5 would need to include additional glare shielding that would probably decrease the efficiency of the system as a whole.

Adopting a T8 lamp also made sense on grounds of running costs and maintenance. A combination of single and twin 58 W T8 lamps enabled both the 300 lux and 500 lux light levels to be met with a single light source. (Using the same number of fittings, a twin 35 W T5 lamp fitting was needed to meet the 300 lux level in normal classrooms, and a twin 49 W T5 lamp for the 500 lux science/art rooms.) This would complicate maintenance and also the risk of the increased brightness of the 49 W lamp would significantly increase the likelihood of glare.

How the fitting should look was important. Talking to BDP's architects the message was that it should be kept very simple: square shapes and circular shapes are the best for integration. It also needed to accept single and twin lamps in the same body and be capable of being surface-mounted, suspended on wires or fixed on to a standard 50 mm x 50 mm electrical trunking. The reason for this was that most of the schools BDP is currently working on have exposed thermal mass, and attaching the fittings to the trunking keeps the design neat and simple.

Steel body

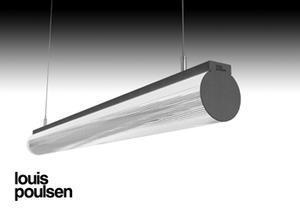

Out of the four manufacturers approached Lupton eventually teamed up with Louis Poulsen.

The luminaire consists of a co-extruded acrylic optic fixed to a simple folded steel body. The optic has two parts - a diffuse opal element that allows a gentle uplight to the ceiling and a custom-designed prism system that controls and distributes the light in the vertical and horizontal planes.

Louis Poulsen designed the fitting in CAD, predicting its photometric performance before producing the first prototype. This was shipped over from Denmark and installed in BDP's offices, where the architects and engineers had a chance to comment and refine the design; a further four versions were shipped before the design was finalised.

An integrated photocell, hard-wired into the ballast, generates a closed control loop that can respond to daylight and the higher initial lumens by automatically dimming the lamp. "It's a simple self-contained solution, which gets daylight control into the scheme," says Lupton, although he admits it is probably more expensive in the long run than a conventional control system.

Cost was another driver in the fitting's development. BDP needed it to fall within the tight budget for the schools projects (around £55/fitting), something Louis Poulsen has managed. It is now selling the fitting on the open market, BDP, however, won't be receiving any royalties. "Louis Poulsen did ask, but as a lighting designer I felt I shouldn't because the most important thing was my independence from any manufacturer. Plus the royalty would have added on to the price." As it is, Davis Langdon will cost the lighting on BDP-designed schools lower because of this standard solution it will be adopting.

The first 400 units have now been installed and BDP is already looking at taking it further. An 18 W wall mounted version is already on the drawing board and Lupton says they will be looking at using it in other, similar applications such as universities.

At the moment he is nervous about specifying it for an office environment but he doesn't rule it out. "It'll be interesting to see if we can get close enough control to take it into commercial environments. I think it has got the potential to deliver a really people-friendly lighting solution, a really soft light that gives a good look and is comfortable to work in with no harsh contrast."

Day lighting

BDP has developed its own design target for daylighting in classrooms. According to Lupton much of the current guidance available to designers is ambiguous. “Up until the CIBS code of 1977 the regulations required a minimum daylight factor of 2% in all classrooms.” This contributed to a generic classroom design with high ceilings and tall windows but the energy crisis meant this was removed as heat loss took priority over daylighting.

One statement, taken from LG10 Daylight and Window Design, which is repeated in most publications relating to daylight, is: “An average daylight factor of below 2% generally makes a room look dull; electric lighting is likely to be in frequent use… an average daylight factor of 5% or more will ensure that an interior looks substantially daylit… ”

“I think we are realising that design needs to be much more about quality of space and long-term sustainability of providing the light from natural means,” says Lupton.

Research that has been carried out by the Pacific Gas and Energy Company in the USA indicates that high levels of daylight are a positive contributor to academic performance. It showed students in classrooms with the highest daylight factors (in the order of 10%)

progressed up to 20% faster on maths test and 26% faster on reading tests.

Taking this and other research into account, BDP settled on an average daylight factor of 4–5% with a minimum average of 3% in all occupied spaces.

Achieving this can be quite onerous. Large windows cost more than solid walls, have a poorer acoustic performance and are worse performers in terms of thermal insulation. To achieve a daylight factor of 5% in a typical 8 m x 8 m classroom with a single external wall requires a glazed area that covers the entire window wall from desk height to the ceiling. A downside of this is that there is a complete imbalance of daylight in the room, something BDP is trying to counteract by bringing light in through the wall facing the corridor.

BDP is currently trying to develop a ‘perfect’ classroom design to be used in schools all over the UK. So far it has established that, in terms of natural and mechanical ventilation, acoustics and lighting, classrooms need to have a minimum floor-to-ceiling height of 3 m.

Downloads

Section through BDP's luminaire

Other, Size 0 kb

Source

Building Sustainable Design

No comments yet