In real life scenarios, however, this is not necessarily the case. Occupants within the neighbouring apartments may well become aware of the incident and in such cases a tenable environment should be achieved on all escape routes.

Contemporary codes require any high-rise (over 11 m) residential building, which has a single staircase to be vented by the use of automatic openable vents. The purpose of providing ventilation to the lobbies and staircase is to prevent the means of escape route becoming compromised by smoke. The intent is not to provide a smoke control system to maintain a clear layer but to provide means of diluting and relieving the smoke within the common lobby. Whether tenable conditions are maintained for the escaping occupants using the staircase is questionable.

Solutions for ventilation

There are further ventilation requirements when an occupied floor is above 18 m, and requires a fire-fighting shaft. The shaft consists of a stair, associated protected corridors serving as lobbies at all levels, and a fireman’s lift. Codes recommend a number of solutions for ventilation, including the provision of manual operable vents on external walls to both lobbies and stair, a pressurisation system or natural smoke shafts serving the lobbies and staircase.

As lettable space is becoming the driving factor and buildings are getting taller, designers are moving away from the traditional long corridor with two stairs towards a short dead end lobby and a single staircase. In most cases designers opt for an internal stair and lobby. As a result a 3 m2 smoke shaft serving the lobby and a 1·5 m2 smoke shaft serving the staircase are required. The alternative is to adopt a pressurisation system.

Although the shaft required for a pressurisation system could be relatively small in cross sectional area, the plant space required can be substantial. Other issues associated with a pressurisation system are initial testing and commissioning, general maintenance and balancing of the system when alterations are made to the building. Another consideration for designers is the provision of pressure relief paths, which in an internal staircase configuration is difficult to achieve.

Where smoke shafts are chosen as the preferred solution, both shafts require an inlet direct from fresh air at the base and an outlet at the head. In addition, automatic vents opening directly into the smoke shaft are required at each level, to the lobby and staircase and a 1 m2 opening vent at the head of the stair, operated by the fire service on arrival. The inlet required at the base can also be a problem. Design implications for taking a 3 m2 or 1·5 m2 duct horizontally to open air and considering adverse wind affects creates more headaches. The result is often a reduction in the net lettable or useable floor area.

Further research

Until recently the validity of natural smoke shafts had not been fully analysed. BRE has scientifically justified that smoke shafts will provide an effective means of keeping the fire fighting stair free of smoke while maintaining tenable conditions within the fire fighting lobby during fire fighting operations. The conclusions of the research showed that smoke shafts without an inlet at the base will perform better than vents located on external walls, see figure 1. However, the research was conducted to investigate the benefits of smoke shafts in fire fighting stairs and lobbies and did not take account of their use for means of escape.

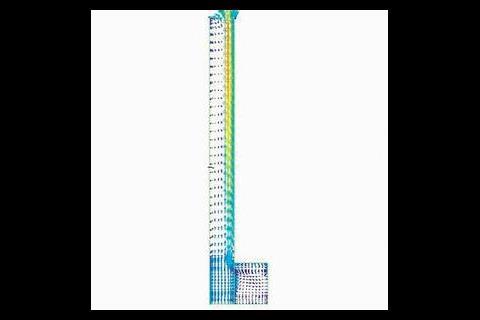

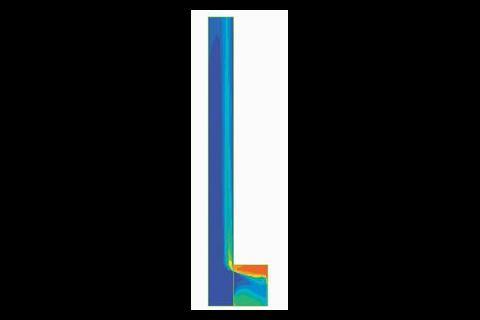

Buro Happold recently carried out a series of further tests at BRE, following concerns raised by various approving authorities with regard to the validity of the 3 m2 smoke shaft and its use for means of escape. A sensitivity analysis was carried out to investigate the effects of opening and closing the door between the fire compartment and lobby, door between the stair and lobby and, most importantly, of the door at the base of the staircase. Computational fluid dynamics was used to replicate these tests as part of the research, which was later used to model different lobby configurations, see figure 2.

The conclusions were that a 3 m2 smoke shaft serving the lobby would provide an effective means of smoke removal, keeping the staircase free of smoke in all conditions while maintaining a tenable environment.

The 3 m2 smoke shaft not only provides the designers with a more workable solution it also has significant cost benefits. As a result of the elimination of openable vents and the 1·5 m2 vertical shaft within the staircase, a greater net lettable area is achieved. Research and testing of smaller sized and fan assisted smoke shafts have been conducted and are becoming available. However, these techniques must be treated with the utmost caution and validated with supporting calculations and in some cases physical testing.

Buro Happold is looking at reducing the 3 m2 smoke shaft to provide an increase in value of the building by the use of fire safety engineering. The basic design principles of the 3 m2 smoke shaft can be summarised:

- A smoke shaft with a cross-sectional area of 3 m2 which extends through the lobbies of the building.

- Automatic opening vents provided in each lobby opening into the shaft having a free area of 1·5 m2. These should operate on automatic smoke detection.

- No inlet is required at the shaft’s base.

- A 1 m2 (free area) automatic opening vent located at the head of the staircase.

- There is no need to provide opening vents at each individual landing to the stair.

However the designer must take account of adverse wind effects at the head of the smoke shaft. Engineers must also consider the integration of the automatic smoke detection with the automatic opening vents and the vent at the head of the stair and certain manual overrides which are required by the fire service.

The 3 m2 smoke shaft design has been utilised on various projects including a number of high-rise buildings in Leeds city centre. An existing building was redeveloped to provide retail, office and residential accommodation within a mixed-use building. The height of the building is just under 60 m.

The escape routes from the retail and office levels were required to be independent from the residential escape routes. A pressurisation system in the fire fighting stairs and lift lobbies was required to aid fire fighting and means of escape.

Flexible solution

In order to comply with prescriptive fire safety standards, protected ventilated lobbies were required to all the residential levels to aid means of escape and fire fighting. Pressurisation was perceived as the only viable option due to the layout of the existing core. Through the use of the smoke shaft and fire engineering analysis it was demonstrated that a 3 m2 smoke shaft without the inlet performed better than the standard 3 m2 smoke shaft which has an inlet at its base, satisfying the requirement for both means of escape and fire fighting provisions.

The elimination of a pressurisation system provided the client with significant cost benefits, a flexible design and increased net useable floor area.

Source

Building Sustainable Design

Postscript

Rav Dhanjal is a fire consultant with Buro Happold Fire Engineering Design and Risk Assessment.

No comments yet