Hull council wants to make flood resistance a condition of planning permission, but is it possible to build a house capable of resisting the recent freakish weather? And would anybody buy one?

The floods of June and July hit 27,500 homes and 7,000 businesses. The aftermath is still with us: many of the dispossessed are still living in caravan cities or queueing for water bowsers. But now that the immediate danger has receded, attention is turning to the future, and the 5 million people living in areas at risk of flooding in England and Wales. How can we ensure that such widespread devastation never happens again?

The city of Hull was one of the worst affected areas, and its council is talking to the Environment Agency about making flood resistance a condition of planning permission. Meanwhile, the Association of British Insurers (ABI), whose members are facing a clean-up bill in the region of £1.5bn, is making its position clear. A spokesperson said: “Some homes might find it impossible to gain insurance in the future if they don’t take on these measures.”

So assuming we’re going to be building a lot of flood-proof homes before long, there are a few questions that need to be answered …

How will they be different?

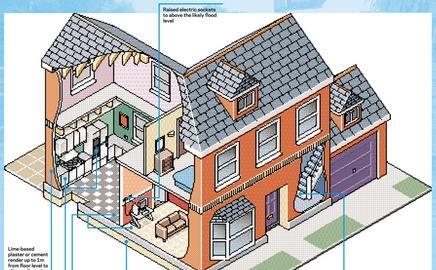

A number of solutions have been suggested to make homes “flood resilient”. All are designed to minimise the cost and damage from water ingress and to get people back in their homes as quickly as possible after the water has left.

The ABI, in association with BRE and the National Flood Forum, has produced a Flood Resilient Homes factsheet which makes the following recommendations:

- Replacing timber floors with concrete and tiling the ground floor, replacing chipboard or mdf kitchens with plastic equivalents

- Replacing gypsum plaster with more water-resistant material, such as a lime plaster or cement render

- Putting one-way valves into drainage pipes to prevent sewage backing up into the house n Moving service meters, boilers and electrical points above the likely flood level.

In addition to these measures, an EU project called Floodplain Land Use Optimising Workable Sustainability (FLOWS), carried out work on a pilot house in Lowestoft, in Suffolk. Electrical sockets were raised to above the dado rail, itself above a 1m expanse of lime-based plaster. The bottom stair was replaced with a concrete one and the floor and skirting boards were tiled. The kitchen was refitted with stainless steel units and the doors were replaced with a lightweight wood that will make them easy to lift off their hinges when the waters hit. Plinths were built for electrical appliances.

How much will they cost?

We gave the specifications to Davis Langdon to find out how much it would cost to implement the measures on a new home. They prepared a costing based on a two-bed property on 300mm raised foundations (see table).

The results showed that the total extra cost to the developer would be £45.55 per m². Davis Langdon estimates that this would mean that a buyer would have to pay an extra 3-4% for the property.

Simon Rawlinson, a partner in Davis Langdon, believes this offers little incentive to housebuilders, who are already facing higher construction and material costs. “These measures are going to have a downward effect on the margins that can be achieved on projects unless they can secure a premium for them. I’d have thought that would be a little difficult to do because I’d imagine most people do not buy a house to be flooded. Quite clearly, somebody somewhere will be out of pocket.”

With the demand for new housing strong and development continuing on floodplains, housebuilders may have little choice but to adopt flood resilience. The question is, whether it will be the developers who are out of pocket or the buyers.

Where will the materials come from?

Whether such materials exist, or could be available in the necessary quantities, is uncertain. Leading figures within the industry are unable to pinpoint suitable materials for the job or confirm that they could meet likely demand. The biggest sticking point seems to be the plaster.

The industry is divided as to whether any plaster could stand up to substantial flooding. The Lowestoft house used a product made from a mixture of lime and gypsum. Lime plaster is permeable and allows the walls to dry out more quickly after a flood. This may be suitable for shallow flooding that recedes quickly, but it may not be able to cope with deep, contaminated water that hangs around. “If the flooding is as bad as we have seen recently,” says Alison McErlain, project manager for the pilot house, “any plaster would have to be removed, particularly if there was any contamination. We’re not saying it is totally resilient.”

So are there any products that could withstand the pressures of the recent floods? Leading industry figures advised that a moisture-resistant plasterboard and water-resistant paint would keep the water out for about 24 hours, but no longer.

At present, there is little demand and therefore little knowledge among the industry for the type of products needed for this type of build.

Will they work?

At this stage, it is hard to say whether anything could stand up to the levels of flooding we’ve seen recently.

When flood waters entered the pilot house a year after the renovations were completed, the property required a quick clean and was inhabitable again within a day. It usually takes one month for every inch of water that gets into a property to dry out. However, Alison McErlain, a planning strategy manager at Norfolk council, and the project manager for the pilot house, warns against drawing too many conclusions from that episode. “We don’t want to lead people to think this is totally resilient,” she says. “There was flash flooding certainly, but the water didn’t come up more than a few feet.”

The effect of sewage contamination and a longer submersion are as yet untested. McErlain thinks it likely that even the house’s lime-based plaster would have to be replaced if confronted by the level of flooding seen recently.

Will anyone buy them?

Although practical, the measures are without doubt visually intrusive. Plug sockets halfway up the walls and tiled floors instead of plush carpets are not the stuff of which dreams are made. Are developers worried that, if they are forced to build in this way, buyers will be put off?

Giles Asker is a divisional operations director at Gladedale and is based in the Midlands, one of the areas hit by the recent deluge. ”Subtly done, some of the innovations would be largely immaterial to a potential buyer and would pose no major problem to marketability,” he says. “Ceramic floor tiles are unlikely to raise concern within a hall or kitchen, but it could be a different story in living areas where they lack warmth. I can’t see steel kitchen units being acceptable to many people, other than as a fashion item, and this could definitely limit the potential market for sales.”

Meanwhile, estate agents wonder whether anyone will buy homes in the affected areas at all. Craig Denby is the assistant manager at the Hull branch of Beercock, Wiles & Wick. He foresees buyers moving away from areas vulnerable to flooding altogether. “It’s not a good thing if you’re a buyer looking round a house that has had to take these precautions,” he said.

Buyers are already voting with their feet. The previously popular new-build Kingswood estate in Hull has become a no-go area for buyers, even though only a third of it was hit. Denby says: “We have been unable to sell properties there at the moment. Three or four that were on our books, which were new properties only six or so years old, have had to be taken off the market.”

Downloads

How a flood-proof house might look

Other, Size 0 kb

Postscript

Email us with your views at building@cmpi.biz or click on “what you think” at www.building.co.uk

No comments yet