It is becoming common for developers to strive for ‘carbon neutral’ or ‘zero carbon’ projects. Typical design approaches minimise energy use and then offset to reach net zero – but how reliable is offsetting in reality? James Robb and Priyanka Arora from Sturgis Carbon Profiling explore a more tangible solution

01 / Introduction

Carbon offsetting is the practice of compensating for emissions by preventing them elsewhere – for example, compensating for emissions by planting trees, investing in renewable energy or funding resource conservation projects. While it may be easy, this widely adopted system for mitigating net global emissions has notable limitations.

The legitimacy and reliability of offset projects cannot always be ensured, for example, afforestation takes many years to sequester the carbon damage being done today.

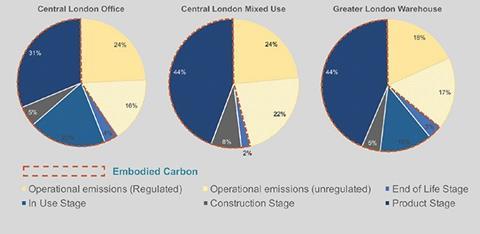

Furthermore, carbon accounting seldom accounts for all emissions. Embodied emissions are typically ignored, though they can account for as much as 60% of whole life emissions in commercial buildings. Embodied carbon emissions can in fact provide huge opportunities for carbon reduction without the need to offset. In addition, reducing embodied carbon emissions will provide more tangible and reliable results than traditional offsetting.

This article discusses how circular economy principles can close in on carbon neutrality and contribute to lower net global emissions.

Two project examples show how this has been achieved in practice, including a project for SEGRO, which involved moving an entire building and an embodied carbon construction policy for Gatwick Airport to implement the same approach at estate level.

Embodied Carbon of Materials: Quick Facts

- Embodied carbon can account for 50 – 60% of whole life carbon in new commercial projects*, analysis of three recently assessed SCP projects is displayed left.

- As a comparison, 100m2 of PV can save up to 150 tCO2e over a 25-year life cycle. Comparable savings using embodied carbon reduction measures are:

| Baseline material Specification as industry standard | Substitute construction material | Comparable quantity | Replacements over a 25-year period |

|---|---|---|---|

| Concrete | Concrete with 50% GGBS** cement replacement | 1,000m3 | 0 |

| Structural steel | Reused structural steel sections | 80 tonne | 0 |

| Carpet | Carpet with 60% recycled content | 10,000m2 | 2 |

* Operational emissions based on values from respective energy consultants

** GGBS (Ground granulated blast-furnace slag) is a byproduct of the steel industry and can be used as a cement replacement at no extra cost

02 / Circularity at building level: Warehouse relocation

The circular economy approach is based on keeping materials in circulation and avoiding waste through reuse and resource efficiency.

SEGRO’s 9 Cambridge Avenue is one example where these principles were applied in practice, saving a redundant warehouse building due for an untimely demolition and relocating it to a new and more economically viable site.

Project approach

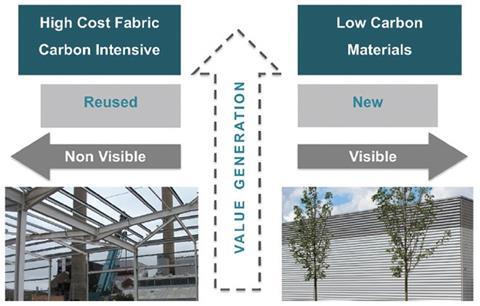

- Resource efficiency Dismantle and reuse building components wherever feasible from the existing warehouse. Specify new components where required, with low carbon footprint considered a key performance indicator

- Value retention In terms of both money and carbon, extending the life of the existing building components added value to the initial investment made. Reuse of high value items such as curtain walling was particularly beneficial to make savings whilst installing new external metal cladding assured a high market value for the project was retained.

An analysis of the finished project was carried out to understand the viability of this approach for future projects. The key achievements and lessons learnt are discussed here.

Key achievements

- 3180m2 of office space and warehousing dismantled and moved to a new location about one mile away

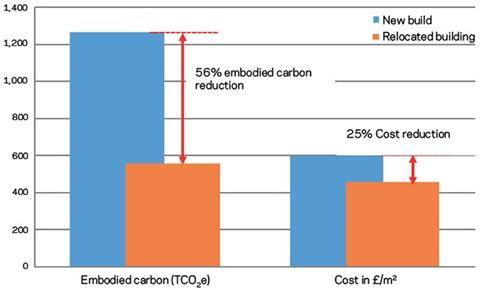

- 25% saving in costs compared with a comparative new build

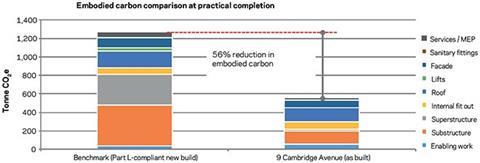

- 56% lower embodied carbon at practical completion compared with a comparative new build, carbon saving of about 700 tCO2e. This saving is equivalent to about five years of operational emissions from this project

- No organic waste created. All waste diverted from landfill.

Breakdown of embodied carbon savings achieved

- Reuse to save carbon and cost

The reuse of building components not only allows embodied carbon savings but also allows a saving in the overall cost of the building, a reduction of almost 25% for this project.

- Low-carbon specification

Specifying a higher recycled content in new components and a higher proportion of GGBS in the concrete for new site works also allows a significant reduction in the embodied carbon footprint

- Whole-life assessment

Consideration given to whole-life performance; the existing boiler was not retained meaning an increase in embodied carbon expenditure. However, the higher efficiency of the new boiler resulted in a lower Life Cycle Assessment (LCA) carbon footprint overall, emphasising the importance of whole life cost and carbon assessment in the circular economy approach

- Future potential The main limitation in this project was that the existing building had not been designed for deconstruction, thus not allowing all potential savings to be realised for carbon or cost. If designed for ease of disassembly and re-usability, the likelihood is that as much as 80% of the material could have been reused, increasing cost savings as well.

| Component | Element | Carbon footprint reduction at practical completion | |

|---|---|---|---|

| KgCO2e/m2 NIA | T CO2e | ||

| Reusing steel structure: |

|

>80 | 260 |

| Plant |

|

>10 | 30 |

| Reusing concrete structure: |

|

>40 | 130 |

| Facade |

|

>9 | 30 |

| Roof |

|

>8 | 25 |

| Internal fit out |

|

>3 | 10 |

| Lift |

|

>8 | 25 |

| Concrete specification: |

|

>60 | 200 |

| Total embodied carbon reduction at practical completion | 220 | 700 | |

Figure 4: 9 Cambridge Avenue: embodied carbon savings breakdown

03 / Circularity at Estate Level: Gatwick Airport

Gatwick is striving to become a leader in sustainability by reducing its environmental impact, with minimal offsetting.

Expanding on the principles of the previous case study, SCP are currently advising Gatwick Airport Ltd on embodied carbon construction policy and practices, with the aim of embedding a circular economy approach to development of the Gatwick estate.

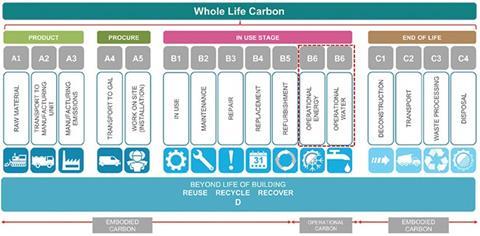

This circular approach to construction “neutrality” for Gatwick will contribute to whole-life carbon thinking at an estate wide scale, accounting for both operational and embodied emissions as per BS EN 15978 Life Cycle Assessment (LCA) methodology. Figure 6 above outlines the stages of assessment:

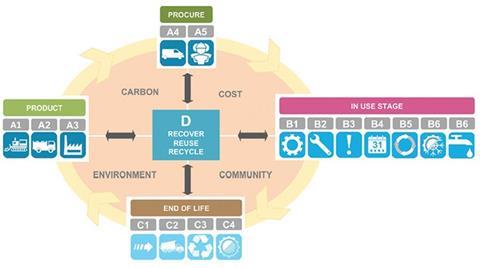

Stage D will form the basis of the circular economy implementation at Gatwick. By giving emphasis to reuse and recovery of existing resources, demand for natural reserves will be reduced, shrinking the carbon footprint of the estate. This has a knock-on effect on all lifecycle assessment stages (A1 - C4) as illustrated in Figure 7, below.

Carbon neutrality in airports

Airports play a fundamental role in globalisation today and the emissions from the aviation industry continue to rise, accounting for almost 6% of UK greenhouse gas emissions. With growing awareness and pressing climate action plans, airports across the world are striving to reduce their own emissions as well as collaborating with suppliers and business partners to reduce theirs. Airport Carbon Accreditation (ACA) is a global carbon management programme with four levels of certification:

- Level 1: Mapping Carbon footprint measurement

- Level 2 Reduction Carbon management towards a reduced carbon footprint

- Level 3: Optimisation Expand scope to include third party engagement

- Level 3+: Neutrality Carbon neutrality for direct emissions by offsetting.

As of a report released in September 2016, 170 airports have been certified to an ACA level.

Of these, 26 have successfully achieved Level 3+: Neutrality.

Neutrality is the highest level of certification offered by ACA. For these 26 airports, it has been achieved by making ongoing reductions in direct operational emissions, procuring certified renewable electricity and compensating for residual direct emissions by purchasing carbon offsets – for example, planting forests, investing in renewable energy or funding resource conservation projects.

Embodied emissions, however, are not included in this calculation, meaning the airports concerned are in reality far from “carbon neutral”.

A Circular Approach for Gatwick through GIS Mapping and Resource Efficiency

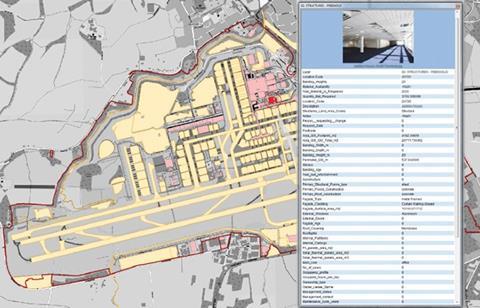

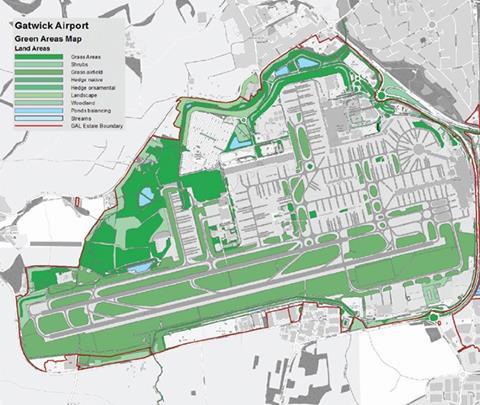

Gatwick has commissioned SCP to set up a Geographic Information System (GIS) model with the capability to:

- Map and quantify all carbon emissions – operational, embodied, whole life and supply chain

- Provide a central visible database of all resources, materials and assets within the estate

- Identify opportunities to reuse existing resources on site for maximum financial and carbon benefit

- Integrate with existing carbon management systems.

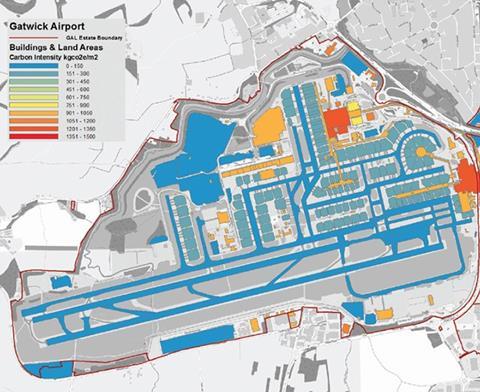

Figure 8: GIS carbon mapping: reallocation of resources to achieve circularity

Initial opportunities for circularity identified from carbon mapping at Gatwick

Reusability and Recyclability Potential at Gatwick:

Of the current estate, 74% of structures have a steel superstructure, the remainder being predominantly concrete. We class steel structures reusable as they can be dismantled and their components reused without reprocessing or down-cycling, especially if design for deconstruction has been considered at inception. Most metals are capable of being continually recycled with no degradation in performance, and from one product to another, as demonstrated in figure 9 below.

In the future, the concept of reusability will be embedded into the development of the estate by ensuring all projects are designed to optimise the following:

- Reuse and recovery

- Deconstruction andflexibility

- Resource efficiency.

Across the estate, the circular economy capabilities, reusability and recyclability of building components, will be mapped. This data held in the GIS model allows emissions to be managed and reduced.

Scaling up the findings of the SEGRO case study to an estate level and embedding circular economy principles into designs could allow embodied carbon savings of more than 60% while at the same time allowing cost savings greater than 25%.

Low carbon specification for hard surfaces alone could reduce Gatwick footprint by up to 9%

Initial embodied carbon analysis revealed that hard external surfaces such as apron, roads, airfield, and so on, make up almost a quarter of the total embodied carbon impact of the estate. The impact of these surfaces is especially important due to the high frequency of their replacement cycles, which can be as little as 10 years.

Following circular economy thinking – considering design, construction and renewal – would aim to minimise waste and the use of virgin material at all stages, and maximise opportunities for reuse.

While airfield surfaces have specific safety and quality requirements, the use of recycled material in other concrete surfaces can allow a reduction of up to 9% in the overall embodied carbon footprint at Gatwick.

Potential for carbon sink

Of the Gatwick airport estate, 39% of the area is made up of vegetation – woodland, shrubs and grass. Vegetation could be further increased by green roofs and walls on buildings, and vegetation around car parks. This vegetation absorbs CO2 as it grows and could be of value for the purpose of on-site carbon sequestration. Sequestration was recently highlighted by the Committee on Climate Change as a valid carbon mitigation strategy. Following an emissions-based hierarchy for end-of-life treatment is crucial to ensure this is of value as CO2e reduction in reality. For example, anaerobic digestion of decaying organic matter or growing timber for use in construction would lead to lower emissions than either landfill or incineration.

Key features of Gatwick’s approach

- Going further than offsetting: The holistic approach taken at Gatwick expands over and above current best practice to measure, control and reduce the embodied carbon footprint of their entire estate.

- Maximising circular economy opportunities: Opening up opportunities to reuse, recycle and recover, reducing carbon and cost at source is a more proactive approach than only buying offsets while allowing inefficient practices to continue.

- Innovation: Analysis has revealed the embodied carbon hotspots of the estate, such as the high impact of airfield pavements.

Acting to reduce these and striving for leadership requires innovative solutions.

We see that environmental impact can be reduced concurrently with costs while also providing a number of positive social impacts for airport users, stakeholders and the neighbouring area.

04 / Conclusion

The two case studies have shown there is much to be gained from taking a circular economy approach – on both environmental and cost grounds.

- Carbon mapping to optimize material flows Carbon mapping can be a very useful and practical tool giving transparency to resource and material flows.

- Cost saving opportunities In the first case study, a cost saving of 25% was achieved for a single building project which had not been designed for deconstruction or reusability. If circular economy principles are embedded into design at estate or wider scale these savings will multiply.

- Circular economy is a reality Using the circular economy to close in on carbon neutrality is happening at building and estate level through embodied carbon reduction. Through increased reuse and recycling, dependency on virgin reserves and sending waste to landfill is discouraged, resulting in lower emissions, before resorting to offsetting. The same methodology applied to communities, cities and beyond would offer an opportunity for a more sustainable and cleaner environment. Benefits are felt when and where a project takes place, with reliable and quantifiable carbon and cost reductions.

Acknowledgements

We would like to thank SEGRO and Gatwick Airport Limited for their input, especially Rachel Thompson and Jon Tivey at Gatwick Airport. Thanks also to Juan Lafuente and Simon Sturgis of Sturgis Carbon Profiling for support in preparing this article.

No comments yet