More and more car parks are adopting the use of impulse fans for ventilation. We explain how and why.

‘Impulse ventilation systems are the most significant new weapon made available to the industry in the last 25 years. The benefits of the system can be reaped not only by the car park owners, but also the users, designers and in the event of fire, the fire service.’ This is according to the British Parking Industry. For years car parks have been ventilated using the traditional method requiring extensive ducting taking up valuable car parking space, however the introduction of impulse ventilation systems removes the need for endless ductwork and instead uses a small number of slim, powerful fans.

Approved Document B: Fire safety and Approved document F: Ventilation cover the recommended methods of complying with Building Regulations. They describe three traditional methods of ventilation for car parks.

Open sided car parks are defined as fully above ground car parks with permanent wall openings on each level equal to 5% of the plan area and arranged to provide cross ventilation. These openings provide sufficient ventilation for both smoke clearance and to remove exhaust fumes.

Naturally ventilated car parks have permanent wall openings on each level equal to 2·5% of the plan area arranged to provide cross flow ventilation. This is sufficient ventilation for smoke clearance, but in addition mechanical extract providing three air changes per hour is needed to remove exhaust fumes. As an alternative to the wall openings, smoke ventilators can be provided in the ceiling to provide the equivalent of 2·5% of the car park area.

Where natural ventilation is not possible a mechanical extract system can be used. This needs to achieve six air changes per hour for exhaust fume extract and 10 air changes per hour for smoke clearance. This system is designed to run in two parts, each one capable of achieving 50% of the required extract rate.

Each part has its own independent power supply to operate in the event of mains power failure. The extract points should be designed to extract 50% at high level and the remainder at low level. The fans must be rated to run at 300°C for a minimum of 60 minutes and the ductwork must have a melting point of not less than 800°C. The ductwork distribution must be planned to the satisfaction of the local statutory authority.

The systems are not intended to assist means of escape in case of fire, but to assist fire fighters by providing smoke clearance. Even a casual inspection of the requirements shows that these methods cannot be expected to do more than limit smoke density and speed smoke clearance once the fire is extinguished. Properly designed smoke ventilation systems can be used, but due to the low headroom available in most car parks they are rarely a practical proposition.

There are also a number of other issues relating to traditional mechanical car park ventilation that cause problems for designers:

- The ductwork runs underneath the ceiling, reducing the already restricted height normally available.

- Downstand beams require the ducting to be set down below them, thus diminishing the height even further.

- Low level extract points are required, often with protective barriers surrounding them, and these take up valuable floor space.

- The ductwork gives the car park a cluttered look and can interfere with cctv coverage.

Impulse ventilation systems are intended to overcome many of these problems and have consequently increased in popularity in the UK over the past two to three years. The system uses the principle of adding momentum to the air to thrust it towards a pre-designated extract point and to ensure that there are no dead spots for fumes and smoke to stagnate and collect. Although the system is relatively new for car parks it has been developed from well proven tunnel ventilation systems.

Impulse systems can be used to replace the traditional mechanical ventilation systems in naturally or mechanically ventilated car parks and can also be used to assist natural cross flow ventilation in large car parks. All the distribution ducting can be replaced by a number of small diameter impulse fans, located to ensure air movement throughout the car park.

The major benefit of the system is that it removes the need for distribution ductwork in the car park. It also provides a safer, lighter environment, and can lead to better security from cctv systems. The installation of the equipment is also more straightforward and can be significantly quicker. Power consumption and noise levels can also be significantly reduced.

Two design approaches can be adopted. The first is a solution designed to provide equivalence to a mechanical ventilation system as covered by Approved Document B and Approved Document F. The extract is sized to provide either 3 ac/h, 6 ac/h or 10 ac/h as recommended. In most car parks only a single large extract point is required, located as far as possible opposite the main air inlet openings. The impulse fans are located over the roadways and the layout engineered to ensure there are no areas where it would be possible for fumes to build up due to lack of air movement.

The second is a more complex system, intended to provide clear access for firefighters to tackle the fire. This system has been used in Europe as a fire-engineered alternative to sprinklers. The system requires an addressable fire detection system so that the site of the fire can be pinpointed.

A control system then starts the selected impulse and extract fans to control the direction of the smoke and provide clear air upstream of the fire. This will allow fire fighters to access the car park behind the fire and bring it under control. This method can also be used to protect means of escape in large car parks with excess travel distances. It is however a more expensive option, requiring more complex controls and additional extract.

Since there are currently no standards or published design methods for design of impulse ventilation systems, design is usually proven by use of cfd analysis. In the absence of robust design codes this allows detailed computation of airflow in car parks, taking into account the often complex geometry of individual buildings. This is often essential to demonstrate to Building Control that designs will perform satisfactorily.

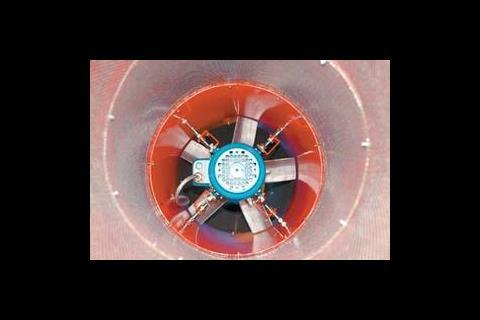

The impulse fans themselves are generally derived from the tunnel jet fans that are seen suspended from the roofs of most road tunnels, taking a similar form but at a reduced diameter due to the low available headroom. They comprise an axial fan with inlet and exhaust attenuators and any necessary guards and flow distribution control devices. Typical outside diameter is 400 mm.

A more advanced system has now evolved in the shape of induction fans. Working on the same principles as impulse ventilators, these fans are slimmer, more efficient and powerful, thus reducing the number of units required. A typical induction fan has a throw of approximately 40 m as opposed to 20 m for an impulse fan. The floor area ventilated per fan is significantly greater, equating to a requirement for fewer units.

There is no single standard control methodology. Currently there are two options commonly used, with variations to suit specific project conditions:

- Option one – for general ventilation purposes the induction and extract fans run at slow speeds. For smoke clearance both sets of fans run at full speed. This option is simple and inexpensive, easy to commission and also to maintain. However, using this method all fans need to run continuously, using energy and creating noise.

- Option two – in addition to the above control, carbon monoxide detection is used to monitor the levels of carbon monoxide in the car park. When in the general ventilation mode, the ventilation rate can be dropped below the normal Building Regulations recommendations as long as the carbon monoxide level remains safe. Approved Document F requires a maximum carbon monoxide level of 50 ppm, but the current EH40 guide from the Health and Safety Executive limits the safe level to 30 ppm. This can simply be achieved by providing an extra low running speed or by using a more complex variable speed system. Whichever is chosen, in a car park with regular quiet periods the energy savings can be significant.

There is no specific British Standard in place for car park ventilation although work has started on one. The proposed standard is BS7346 Part 7. This will cover all methods and aims to set basic functional requirements. The Approved Documents do not currently address impulse ventilation, but Approved document B is due for review starting later this year and we hope that the opportunity will be taken to add requirements for impulse systems.

Due to their benefits, impulse ventilation systems for car parks have a significant role to play and good supporting legislation and standards will aid their acceptance and provide guidance for designers and Building Control.

Source

Building Sustainable Design

Postscript

Paul Compton is fire and smoke control executive for Colt International. For further information on car park ventilation, please contact David Mowatt, Colt International on 023 92 451111.

No comments yet