Skelton Grange Environment Centre aims to educate the local community about sustainability and renewable energy. We find out how the building has been running for its first year.

The initial brief for the Environment Centre at Skelton Grange in Leeds was to provide a teaching facility for the local branch of the British Trust for Conservation Volunteers (BTCV). The building, which replaces a run-down temporary building on their nature reserve, had to accommodate an office, workshop, kitchen and toilets as well as the main teaching space.

Leeds Environmental Design Associates (LEDA) produced an initial feasibility study in 1997. Jennie Holt, project manager for the centre, explains the aim of the project: “We have 5000 school-age children visiting each year. We wanted a building that could inspire them, as well as having better facilities such as more toilets! We also wanted to practice what we preach about the environment. We don’t just have children visiting the centre and our aim is to educate the wider community about environmental issues. We want to show that all of us can do something.” Holt and other volunteers raised £450 000 over five years. The building went out to tender in the summer of 2002, started on site in February 2003 and was completed in June 2003.

LEDA used a number of workshops with the client and key building users to identify aims and uses. Matthew Hill, director of LEDA says: “We tried to get everyone working as a team from the start.”

The primary use of the centre is as a teaching space for classes of young school children who visit the nature reserve, so movement of groups of people into and out of the centre needed consideration. Design team discussion produced the concept of an unheated “buffer space” in the building that could act as a passive solar collector, a draught lobby big enough to accommodate 30 children, and a plant conservatory. Basic calculations of heat losses, solar gains and daylighting were carried out at feasibility (and throughout the detailed design stage) resulting in a number of modifications to such things as window sizes and locations.

When drawing up a services strategy for a building intended as a showcase of best environmental practice, incorporation of some form of renewable energy was an obvious choice. Justifying this in economic terms however can be difficult. Simple pay-back periods for photo-voltaic installations, for example, are over fifty years at current electricity prices. When working within a limited budget LEDA also faced a potential conflict between investing in the most energy efficient building services and specifying renewable installations.

The principle adopted for Skelton Grange was to specify what was considered best available services in terms of efficiency whilst allowing simplicity of design to keep costs within budget. Additional capital sums were allowed for renewable energy sources and justified on the basis of showcasing available technology rather than providing quick pay-back periods.

Various site specific factors affected the development of the design, not least the absence of any natural gas distribution pipework near the site. This prompted consideration of using a heat-pump as primary heat –source for the building, using pipework buried in horizontal trenches.

The effectiveness of a ground-source heat pump is dependent upon its seasonal co-efficient of performance (cop) in operation, which is around 3.0 for typical installations (1). At Skelton two site factors contributed to ensuring a high cop. Firstly, the proposed use of a leachfield for drainage meant one area of land would be kept moist (providing improved heat transfer); and secondly the presence of a 275kV underground cable feeding West Leeds running across the site. Permission was given by the cable owners to install heat-pump pipework 0.5m adjacent to this cable allowing it to benefit from the heat generated by the cable resistance.

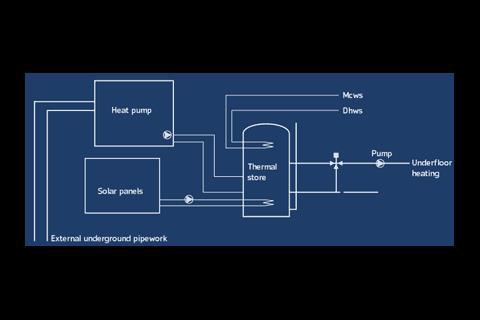

The choice of a heat pump (a 13kW output Viessmann Vitocal 300 model) largely determined the rest of the design strategy. As the temperature output of the heat pump is typically around 50°C, underfloor heating was an obvious choice for heat distribution. Manufacturers Viessmann recommend a buffer store between the heat-pump and the heating load to reduce short-cycling of the motors. A 280l thermal store was specified which acts both as a buffer and a store for the output from roof-mounted evacuated tube solar panels (see schematic diagram above). Domestic hot water is provided from a high recovery coil in the thermal store. This arrangement was adopted to take advantage of any available heat from the solar panels to feed into the heating system in winter (as opposed to just contributing to domestic hot water).

The arrangement shown also allows for a relatively simple control strategy. The heat pump operates during occupancy hours to keep the thermal store at a temperature of 55°C, and will hold off if the solar panels (which have a stand alone controller) heat the store above this temperature. A programmable thermostat linked to the underfloor heating pump provides time and temperature control.

The turbine and photovoltaic array are connected into the incoming three-phase supply panel via inverter units approved for direct grid connection. This means that the clients will receive little, if any, economic benefit from exported electricity (on sunny, windy weekends for example). However the alternative of installing a battery store has the disadvantage of reduced overall system efficiency. The capital costs of a battery store with large enough capacity for two days’ full output generation would have been over £5,000. A ten to fifteen year expected lifetime would negate their potential financial benefit.

The project has now been running for a year, with energy use figures shown in the table. Hill says that a number of important lessons can be drawn from this small project. Firstly, the integration of renewable energy sources into a project requires an analysis of all energy using and energy generating equipment to assess their impact on the prospective annual energy balance. Bolting on photovoltaic panels to a conventional design does not make a building sustainable.

Also, lack of demand and contractor’s ignorance of installation methods contribute to the high costs of small scale renewable energy installations. On this project the lack of availability of wind turbines in the 3 – 20kW output range, for example, meant that a smaller than desired turbine was specified. He also emphasises that adopting an integrated design approach is necessary if the benefits of, for example, increased insulation levels are to be properly assessed.

For Skelton Grange the available budget only allowed for relatively simplistic modelling and prediction techniques. Larger projects justify more careful modelling only if the whole team is prepared to change designs in response to the results. Skelton Grange demonstrates the value that imaginative and practical engineers can bring to a project which aims to achieve much on a tight budget.

Reference

1 Closed ground source heat pumps, Robin Curtis.CIBSE Conference 1996

Source

Building Sustainable Design

No comments yet