The refurbishment of Guy’s Dental Hospital has brought the teaching centre into the 21st century – and provided Faber Maunsell with a project to get its teeth into.

This is where budding dentists come to learn how to give you a set of pearly whites to rival Donny Osmond’s. And the recent refurbishment of the 20-year-old training centre at Guy’s Dental Hospital means the nation’s teeth will be in safer hands than ever.

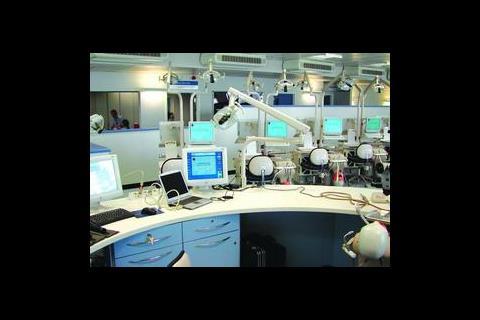

Part of the remit to bring the centre up to modern standards was the installation of 120 “phantom head” work stations, on which students can practise dental work. Each work station is linked to a local computer and LCD monitor so that students can work through training videos at their own pace. The training area itself is divided into four zones, with work stations in the two main areas linked to a central control desk, enabling tutors to monitor and teach the students individually or in groups.

Faber Maunsell had the task of designing the services installation. “As a result of the detailed nature of the dental school workpieces, visibility was a primary consideration,” says Greg Lange, project manager at the firm. Although most of the work on the phantom heads is carried out with task lighting, many of the workpieces are examined and worked up on on the laboratory benches without additional lighting. This called for a high illuminance level of 1000 lux, which has been achieved using semi-recessed downlighters with T5 linear fluorescent lamps. The fittings protrude slightly into the room, allowing a wash of light across the ceilings in addition to the downlighting.

As a result of the nature of the teaching schedule, the areas are generally fully occupied or completely empty so the lights are manually controlled and switched in zones as necessary. “In order to prevent a single late-working student using power for an entire zone, there is a remote master switch to cut mains power to the student workstations,” says Lange.

The air-conditioning is provided at high level so Faber Maunsell coordinated the lighting and fan coil units to ensure the luminaires do not interfere with the airflow.

Space for routing the services was tight. The majority is run through the shallow raised floor or diverted through a plantroom on the floor beneath. In addition to power and data cabling, the workstations are served with compressed air and some with natural gas fuelling burners used for working with plastics. Other features of the of the project include the supply of electricity to special desktop boilers for wax removal from moulds. All in all, pulling teeth has never been so painless.

Client King’s College London

M&E consultant Faber Maunsell

Architect Lewandoeski

Quantity surveyor Northcroft

Source

Building Sustainable Design

No comments yet