For one chilled ceiling manufacturer, the Holy Grail has been to produce a chilled ceiling system that has a cooling capacity over the active area of 100 W/m2 at a differential temperature of 10 K (dt).

A chilled ceiling was developed by Burgess Architectural Products and Hydroclima for testing in a generic office scheme proposed by the consulting engineer, GW Building Services Consulting. The scheme is a representation of a typical 6600 m2 speculative office development, and GW was looking for a chilled ceiling that could handle building occupancy loads of 50 W/m2 in conjunction with a chilled perimeter beam to offset solar gains of 120 W/m2.

The ceiling arrangement proposed used 1280 mm square pivoting Megapanels on a 1500 mm modular grid. This meant that the active ceiling area had to provide a cooling capacity in excess of 70 W/m2 while maintaining a water supply temperature of 15°C and the room at a comfortable 24°C.

The cooling capacity target was over 15% higher than the average for a typical chilled panel.

Standard performance test

The manufacturers developed a heat exchanger consisting of a flat aluminium plate (less than 5 mm thick) with integral titanium-lined waterways that are designed to spread the mass of water across the entire area of the plate. This promoted a highly efficient transfer of energy from the surface of the ceiling tile to the water.

BSRIA tests carried out in accordance with DIN 4715 showed that the system could achieve 74 W/m2 at a 7·5 K dt (and 100 W/m2 at 10 K dt).

As-installed performance test

The DIN testing regime however creates a rather artificial environment. The tests make no allowance for actual use in a working environment and take no account of the air movement generated by the ventilation system.

As these variables are project-dependent, the only way to arrive at a truly representative performance is to test the specified environment. This meant building a mock-up of the chilled ceiling as specified, together with appropriate lighting, heat loads, solar gain, air delivery and air extraction.

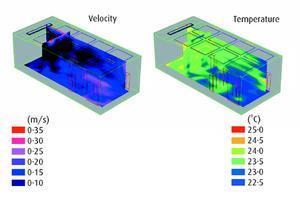

In order to provide additional guarantees of the performance of the chilled ceiling in a generic office, tests were carried out at BSRIA using a mock-up. The test office measured 7200 mm by 3400 mm and was provided with eight active elements (figure 1). Fresh conditioned air was introduced at perimeter ceiling level and extracted through the light fittings. Solar gains, people and equipment were represented by heating elements.

A visual representation of the resulting temperature and air velocity throughout the whole room is presented above. This shows a consistent environment and demonstrates that the room will achieve the desired occupancy comfort.

The chilled ceiling performance for two differential temperatures is shown in tables 1 and 2. Note that the data are independent of the cooling effect of the supply air.

Downloads

Figure 1

Other, Size 0 kb

Source

Building Sustainable Design

Postscript

Graeme Owen and Greg King are with the MicroClimate Centre at BSRIA.