The first BSj/BSRIA Bright Spark award has been won by a team of engineers who have drawn inspiration from the insect world. Here we give the low down on how it is being applied to evaporative cooling.

From the Namib Desert to the top of a cooling tower on a city office block. It’s a long journey, but a short leap of the imagination for one group of engineers, who this year took the BSj/BSRIA Bright Spark Award.

We hear a lot about energy efficiency, and the need to conserve power at all costs. However, water is also in increasingly short supply and the building services industry is one of the more conspicuous consumers of this precious resource. The problem for building services is most acute when we consider the amount of water evaporated in cooling systems.

Inventa Partners and JDP building services consultants took this problem to Dr Chris Lawrence and Dr Pete Hobson of Qinetiq (formerly the Defence Evaluation and Research Agency). Lawrence and Hobson had been working with scientists at Oxford University to develop a material which extracts water droplets from saturated air under certain climatic conditions.

The inspiration for this material is the Namibian desert beetle, or the Stenocara. The beetle survives in harsh conditions of up to 50°C using its wings to collect moisture droplets from the early morning desert air. By mimicking the wing surface of the beetle, Qinetiq has developed a material that tests show could capture over 10% of the water that is routinely lost from evaporative cooling systems.

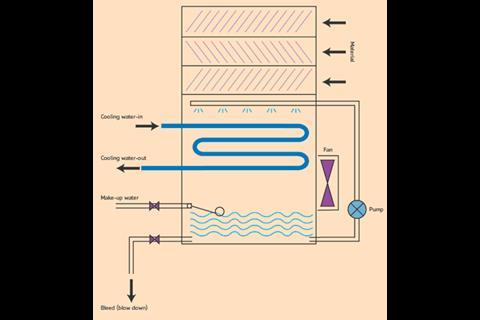

The material, in the form of a film, is applied to slats that are placed in the airstream above a cooling tower. Water collects on their surfaces, running down against the airflow to be collected and recycled as required (figure 1).

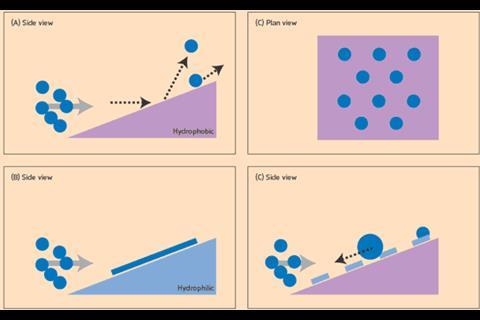

The material consists of a hydrophobic surface (water repellent) on which a series of hydrophilic (water attracting) patterns of specific design are printed. This combination both attracts and repels water (figure 2). This enables the aggregation and capture of a significant proportion of the water vapour that passes across the surface.

If the surface were purely water-repelling, then the micro-droplets of the water would simply bounce off or roll, to be carried away by the wind. If they were only water attracting, droplets would stick in a flat film that is difficult to detach and collect from the surface – discouraging further water harvesting. The combination of the two however, ensures that small droplets are caught at ‘seeding points’ where they aggregate to form large droplets that detach and roll into the headwind safely due to their high mass.

Preliminary trials have been undertaken at Qinetiq’s Farnborough site. Air was driven between parallel plates coated with the material. These plates were tilted so that droplets couldn’t simply be driven between the surfaces. Plena were used to hold the slats in a set pattern with a horizontal spacing.

Water consumption was calculated by measuring the water flow in and out of the system over the course of 24 hours. The difference between the two values corresponded to the amount of water evaporated and lost in the heat rejection process. By comparing this loss both with and without the material, its value was determined.

Calculated reduction in water loss from tests to date is around 10%. However, the inventors believe that the materials have yet to be optimised. The 10% savings so far indicated that even an unoptimised material offers reasonable performance under certain conditions. There are many possible variations on the geometries and materials that can be used to improve water capture.

In practical manufacturing terms, the developers believe that the most economical approach will be to print onto pre-treated polymer sheets. These films could be made using standard printing techniques. These would then be attached to surfaces in the cooling tower, probably removable metal slats which can be removed, rearranged or replaced as required. Replacement would only be necessary if the materials become dirty or abraded, or the operating wind speed of the tower is changed.

Most importantly, the developers point out that the material requires no power, is maintenance free and can be potentially added to existing systems – making it also energy efficient.

Source

Building Sustainable Design

No comments yet