Heather Marsden, one of the services engineers on this project, explains that it was a two-phase build: "The first phase opened in September 2002 and the rest of the building, the larger section of it, would be occupied in September 2003." Due to the school's unique type, it was opened by Tony Blair and his minister for education Charles Clarke. Finishing late was not an option.

But the two-phases did have an advantage: "It was a good thing for us as engineers because it meant we had one smaller part of the building running for 12 months," explains Marsden. "When we came to do the natural ventilation on the larger, second section we had a good idea of what was going to happen and what we had to do."

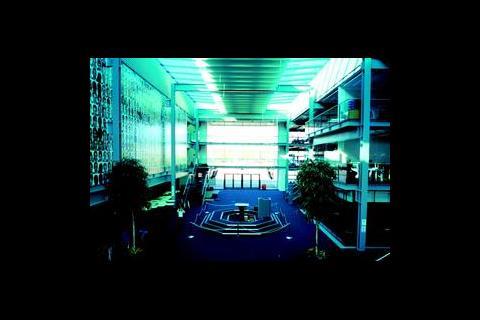

The building itself is a three-storey structure. It has three 'fingers' extending at 90° from a central section. The main entrance is on the west side, and visitors enter a reception area with full height atrium. The two external fingers contain the majority of classrooms. The central finger contains science laboratories. The main reception area is also a 'business court'. "City academies all have a specialism. At Bexley, it is business, so this area has to have a feeling of commerce," says Marsden. As part of this theme, there is a futures trading 'pit' in the floor of the atrium, with electronic financial displays. There are also courts between the three fingers dedicated to art and technology.

Buro Happold adopted a natural ventilation strategy for classrooms. The school is open plan, with classrooms on the external fingers open to the inside of the building. "We have a glazed partition with high level automatic windows and a lower level manual windows. There are also low-level radiators. There's nothing on the internal side, as that's open to the main space," says Marsden. Warm air exits via the courts through automatic high level vents in the rooflights.

External blinds control solar gain, tracking the sun path automatically. There is manual override for teachers who want to grey-out the classroom for use of overhead projectors (see box for more details).

Bexley Academy's open plan design was put into action before the introduction of new acoustic regulations in Building Bulletin 93. However, the school wanted an open plan approach as part of its educational philosophy – younger students entering the building can see what they will become; their future is on show. "A lot of it is down to the management of students," says Marsden. "If people are going to be noisy when they change classroom, it would be a problem. But if they are considerate to each other, it's a different matter."

The central finger of the building which contains laboratories and workshops is mechanically ventilated. They have suspended ceilings, with the associated ventilation units on the roof above.

Bexley Academy sits adjacent to the existing school. Its three-storey design means that it has a smaller footprint than the older building, which helped gain planning permission on this cosmopolitan greenbelt site. Structural engineer Angus Palmer explains: "The architect has left structures exposed. This includes steel columns which punch through the building fabric, leading to potential issues with cold bridging. A thermal break, using neoprene, deals with this issue." Prefabrication was a key step in meeting tight building schedules. "We used a prefabricated system with exposed steel and precast Bison planks," says Palmer. "The planks go down, topping goes onto that and then electrical services can be installed. It requires close integration with the building services."

This last point is central to the success of the project. Close co-operation with the client, and among the design team, has been critical in creating the right learning environment. The occupants had clear ideas about what they wanted from their building. Marsden comments: "There are guidelines from the DfES, of course, but each teacher wanted to do things their way. It is possible to design for that level of flexibility. There were lots of people's views to take into account – but that's what the job is all about."

Blinded by science

Each of the three storeys on the south and north side of the building is protected by the louvres, which are each 3·5 m tall and 500 mm wide. The framework for the louvres is fitted to the school’s exposed external steelwork on prefabricated stubs.

Louvres are individually manufactured from extruded aluminium in one piece with a satin anodised finish. This provides an tough surface for easy cleaning. In total, there are around 2000 m2 of louvres, amounting to approximately 60 tonnes of extrusion.

The louvres track the sun’s progress automatically, moving 120° in total, but there is a manual override facility for teachers to grey-out their classrooms. If the louvres are closed by one teacher, and then left, they will return to the ‘automatic’ position after two hours.

The louvres are controlled, in groups of 12 on each storey, by motors. These are housed beneath the louvres in four specially manufactured housings which run horizontally along the length of the building beneath the louvres. The motors are hidden from view for security and safety. They also have their own battery power backup.

Bespoke software, designed by the manufacturer, uses programmable logic to avoid the problem of ‘hunting’ on cloudy days. There is a time delay before the blinds open or close. At weekends the louvres provide added building security by returning to the fully shut position.

There is a second phase of development on the Bexley Academy site. Another older school building is to be transformed, for junior-age pupils. As part of the major refurbishment, Levolux is creating a tubular steel framework which will support horizontal, fixed-angle louvres. This will be placed around two sides of the smaller, two-storey building. The louvres will sit approximately 4 m from the walls of the building, providing solar shading and an architectural feature which will link it to the larger school.

Source

Building Sustainable Design

No comments yet