As the world’s sporting greats prepare for the supreme test, in Beijing four breathtaking buildings are also being readied for their star roles in the Games.

Terminal 3, Beijing airport

Imagine an airport terminal capable of housing all five of those at Heathrow, then add 17% more space. That gives an idea of the vastness of Beijing’s Terminal 3, which opened in February – with no significant glitches.

The main challenge was not so much the size as the deadline, says Joe Sumners, Arup’s M&E design team leader on the project. There was just over four years between winning the contract to opening the building.

Speedy completion was helped by modular construction – the Chinese way, as Sumners describes it. “They say that modular means ‘bring the factory to the site’. You bring in the raw materials and they bring in 1000 welders to do the job right there, then move it into place. This is very labour intensive, but labour is less expensive.” At the height of construction, up to 50,000 workers were on site.

The authorities wanted everything procured in China, although goods manufactured locally by foreign firms were acceptable. “We couldn’t import large air-handling units from the UK into Beijing and put a Chinese label on it. They were looking to get that technology to enhance their own industrial base,” says Roger Olsen, Arup’s lead HVAC designer on the project.

The biggest air-handling unit delivers 27.9m3/sec. “Not so big, but that was deliberate,” he adds. “The Chinese went for large numbers of a commonly available unit instead of fewer but larger, possibly bespoke, units. A key element of the project was repeatability of a design to reduce the number of different spares needed.”

Sustainability is something the Chinese are just getting to grips with, and they aren’t into green bling. The architect wanted to maximise natural light to cut energy costs but the window area had to take into account Beijing’s extreme temperature range, from -20ºC to more than 40ºC. After a thermal study Arup settled on 155 triangular rooflights. From the air they look like dragon scales, according to the Chinese. The target is for the lights to be turned off 85% of the time during daylight hours.

Client: Beijing Capital International Airport

Design team: Foster+Partners, Arup, NACO, Beijing Institute of Architectural Design

Gross floor area: 930,000m2 (exc basement)

Opened: February 2008

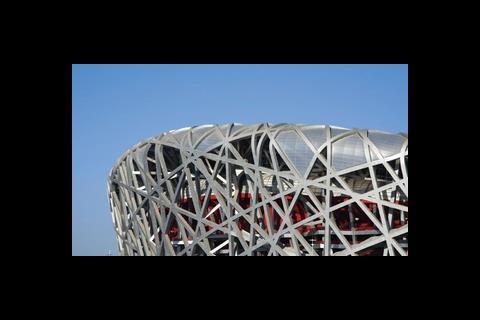

National Stadium

This 91,000-seat venue will be the icon of the 29th Olympiad, hosting the opening and closing ceremonies as well as the track and field events. Its extraordinary design has earned it the nickname of the Bird’s Nest.

“Just looking at the architect’s image, we knew we would have a major design challenge,” Paul Entwistle, head of Arup’s mechanical design team, says. “The lattice steelwork is wonderful but we couldn’t start sticking HVAC louvres on the side of it all. We had to think out of the box.”

ArupSport literally had to dig its way out of the problem to ensure plant and equipment did not impact on the appearance. Ventilation shafts were dug beneath the building to vent discreetly within surrounding landscaped areas.

The estimated heating load is 21.5MW, including 1.8MW for hot water. The heating source is a local district heating system. For cooling, the estimated load is 15MW, provided by water-cooled chillers located in remote plant rooms outside the stadium.

After the Games there is expected to be a significant increase in cooling load generated by the commercial operations using the stadium, so space was allocated for additional cooling and thermal storage to provide a peak capacity of about 80MW.

“There simply is not much external area to deal with heat exchange,” Entwistle says. “Chillers had to be set inside recessed areas below the pedestrian concourse level that runs around the building. The recessed areas had to be oversize to allow space for air movement around the cooling towers.”

Primary air ventilation systems are located at the lowest of the six levels, and distributed to serve accommodation in the stadium by a series of 12 risers located within each of the primary structural cores. Secondary air-handling systems and fan coil units provide conditioning of individual rooms. Catering exhausts and toilet extract systems discharge externally at high level on the external elevation through discreet air exhaust terminations co-ordinated with the 69.2m high structure.

Client: National Stadium Company

Design team: Herzog & de Meuron, Arup, China Architecture Design & Research Group

Gross floor area: 254,600m2

Opened: April 2008

National Aquatics Centre

The straight lines of the swimming venue suggest, at first glance, a more traditional building than the neighbouring National Stadium, but the bubble glass facade gives a hint of the services innovation within.

The Water Cube, as it is known, is one of the world’s largest ETFE-clad buildings. About 100,000m2 of ETFE pillows, up to 9m in diameter, is fitted into a complex network of nearly 24,000 steel bars and 12,000 nodes. This allows the building to capture 20% of the solar energy falling on the roof and is expected to cut lighting costs by upwards of 55%.

The interior is divided into three sections: the 50m Olympic pool and adjacent diving pool, a 50m training pool, and a public leisure area including a wave pool, wading pools and a sandy beach. For the Games, about 13,000 temporary seats will be added to the 4000 installed permanently.

The Arup team wanted to utilise the greenhouse effect to cut energy use. Summer temperatures of 40ºC allow for good radiant heating but cold winters make heat loss an issue, as well as excessive condensation. Arup’s solution involves a double-walled ETFE skin with the heating and cooling channelled between the skins where it can be used most efficiently.

The original design called for movable foils within the bubbles that could be slid open and shut. The cost forced a rethink, and instead there are two films of immovable frits within the inner bubbles, with the pattern of one layer offset against the other. This presents a more solid frit pattern against the direct rays of high summer sun, but low-angle winter sun can pass between the films, allowing more radiation in.

Air-handling units in the basement blow warm air up through 400mm diameter nozzles situated at 1m intervals along the base of the walls. The temperature around the main pool, ideally 28-30ºC, and fresh air, which is essential for the competitors, is controlled by a series of air nozzles located 15m above the water surface. Complete air changes within the building occur twice an hour, with a rate of 700m3/sec.

Client: Beijing State-Owned Assets

Management Company Design team: PTW, Arup, China State Construction & Engineering Corporation, Shenzhen Design Institute

Gross floor area: 70,000m2

Opened: January 2008

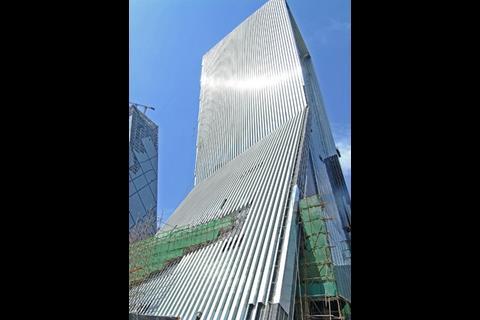

China Central Television HQ

The 234m tall headquarters for CCTV has been described as a three-dimensional cranked loop. Television production facilities are in one of the leaning towers while the other, called the Television Cultural Centre (TVCC), includes public facilities such as a 280-room hotel and a 1500-seat theatre.

The main plant for both towers is contained in a separate outside support building. Continuity of operation is provided by two 63MVA secure independent electrical supplies at 110kV. These share the load but can each support the full load should the other fail. A 3MVA standby generator capacity backs up the secure HV supplies in case of catastrophic power failure.

Within the CCTV building, VAV systems with terminal reheat were decided upon. A more traditional fan coil set-up has been installed in the TVCC tower.

The TV studios vary in size from 2000m2, with a large audience, to less than 100m2. The bigger studios are zoned and have dedicated air-handling plants with direct connection to outside air. This was not feasible higher up the building, so small plant rooms have been located adjacent to those studios, with ventilation air from the VAV system.

The support building above ground will accommodate 200 security staff plus garage and maintenance space for the TV outside-broadcast vehicles. Roof-mounted cooling towers for the chillers and generator coolers require careful acoustic selection to meet the noise requirements at the site boundary.

Below ground, the support building is the heart of the CCTV operation, containing the incoming power supplies and main transformers, standby generators, chiller plant including ice storage, and incoming district heating supplies and associated heat exchangers and pumping station.

Client: China Central Television

Gross floor area: 540,000m2

Design team: OMA, Arup, East China Architecture and Design Institute

Opening: due summer 2008

Source

Building Sustainable Design

No comments yet