Perhaps it was wise for architect Lord Foster to cloak the copper-roofed Reading Room in Spanish limestone. It certainly fits well with the restored south portico and floor of the Great Court. But something of the 1857 building's modesty has been lost in the transformation. It's now much less of a fragile iron-framed turret, and rather more of a pillbox.

Still, there's no doubting the grandeur of the Reading Room's restored interior. The cracked and crazed Victorian plasterwork has been repaired, repainted and regilded, and a compound-curved lattice-shell glass and steel roof now protects it from damaging swings in temperature and humidity. The 4300 m2 Great Court itself houses galleries, shops and a restaurant, while and education centre, auditoriums and seminar rooms are in a two-level basement.

The calm, daylit serenity of the recreated Great Court gives little clue to the enormity of the four-year, £97 million reconstruction, which sees the Reading Room open to the public for the very first time. Work began in 1996 with a long and detailed analysis of the building's structural condition. This was followed in March 1998 by the demolition of redundant book stores, a massive site excavation to create a 9 m-deep basement, and the installation of a new structural and services infrastructure.

Having worked with the architectural team from Sir Norman Foster and partners both on the winning competition entry and the subsequent scheme design, Buro Happold was appointed by the British Museum as the structural and building services engineers, fire engineers and planning supervisors for the project. Mace was appointed as the construction manager and Sulzer Infra as the main m&e contractor for the £6.5 million m&e contract.

Mace carried out a full structural and services audit, tracking and isolating every cable that ran across the site. An 18-month site 'sterilisation' exercise also identified any structural problems, but in the event little serious deterioration was found.

The reconstruction works had to be carried out while the museum remained open to the public, and without generating too much noise and vibration. 28 000 m3 of excavation and demolition material was craned out of the site, while three small tunnels in the basements of the surrounding buildings were used to sneak in construction equipment and prefabricated components.

The environmental strategy

The designers had to find a way of servicing the Reading Room as well as two auditoriums and several seminar rooms beneath the Great Court.

"There was no getting away from the fact that we had to move 40-50 m3/s of air through a Grade One listed structure" said Buro Happold's director of building services, Neil Billet. Where possible, the engineers made use of the existing services routes. Primary plant – notably the fresh air plant – was shoehorned into both new and existing rooms in each quadrant of the site (see left).

The Colt Holland ahus draw tempered fresh air at 2·4 m/s into secondary plantrooms serving a new ring main beneath the Great Court, where the air is conditioned, filtered and recirculated as required. (The need for new boilers was avoided by connecting heat exchangers to the museum's existing heat raising plant, but two additional chillers were required). Extract is managed by the reuse of spiral stair shafts within the historic porticos.

The ventilation systems range from close control air conditioning for the exhibition gallery areas, achieving tolerances of within 1°C and 5% relative humidity, to the relaxed conditions of the Great Court itself.

The Great Court is treated as a tempered rather than a fully conditioned space, as Buro Happold's director of building services explains. "Conditions in the Great Court were partly about having comfort for a cup of coffee, and partly about having a balanced thermal environment for people circulating in the museum.

"At one point the British Museum wanted us to have very high levels of cooling in summer, but we went through the process and came to the realisation that it was probably a disadvantage to do that, as they will probably retain parts of the museum that won't have cooling" added Billet.

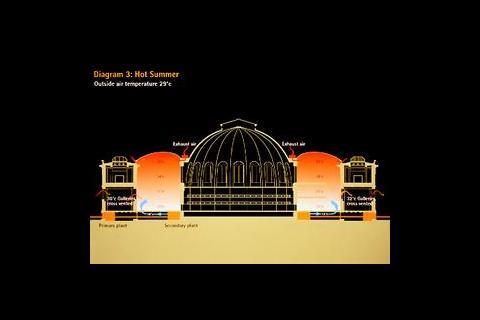

The Great Court's glazed roof was the engineer's first line of defence. Its 0·27 shading factor keeps out 70% of the solar gain, while a system of perimeter louvres behind the east and west porticos can be opened in summer, When wind direction allows, these vents can be co-ordinated to provide cross-ventilation.

If the glass and the stack ventilation is not enough, the next mode of operation is to use the smoke ventilation system hidden in the interstitial space created between the original brickwork of the reading room and its new stone cladding. In summer the system can be used on a half-speed setting to extract hot air.

For winter warmth, the engineers have installed an underfloor heating system embedded in the limestone floor slab of the Great Court. This will run at about 35°C at 10°C ambient. In summer, the chillers can also be used overnight to cool the slab.

"The slab has been fitted with temperature sensors, and there are also temperature and humidity sensors located on posts in the space to help avoid condensation forming on the floor", said Neil Billet. "If needs be we can reverse it and put the underfloor heating back on".

Additional ventilation has been provided by injecting air across the Great Court floor from a perimeter slot diffuser. "This diffuser connects to a corridor opening directly to the outside, which means we can open the louvres and get some natural stack effect through the corridors, into the Great Court, and out through the roof" explained Billett. "When that's not doing enough cooling, we can shut the louvres in the plenum and pump a limited amount of slightly dried, slightly cool fresh air through displacement grilles".

To avoid creating a fountain of cold air, the designers installed a special cam unit beneath the displacement grille to turn the air through 90° and force it horizontally across the floor. "As the floor slab is being chilled, the cool air sticks to it" said Neil Billett. "We've found we can throw it 25-28 m before it loses convection" The Great Court's terrace restaurant is located directly beneath the fritted glazing. Comfort conditions are maintained here by creating a 'cool oasis' microclimate using chilled floor slabs, displacement ventilation, and an internal shade canopy to reduce the sun's direct radiant heat and glare.

During the enabling works, Happold's engineers discovered that the Reading Room was ventilated via a radial network of tunnels – nicknamed the 'spider' – serving spigots connected to desk outlets. The engineers have retained this system, albeit with insulated ductwork, and used fan power to move the air rather than the old Victorian approach of heating pipes in the tunnels to generate convection.

Overall, the Great Court project has doubled the number of mechanical systems managed by the British Museum's engineering staff. "It's going to be another six months before we are happy with the performance of the system" said Neil Billett, "but we want to watch it over a full year and see what really happens" he said.

Worth noting is the early appointment of the commissioning managers, Dome. This meant that the commissioning strategy and the electronic operating and maintenance manuals could be incorporated into the tender documentation.

"It's very easy to forget that the museum was open during the life of the project, and that's not an easy thing to do" said Billett. "Mace handled that extremely well, but it was everyone's policy to tread as lightly as possible on the existing building. Without doubt the planning strategy....has been a key element in enabling this project to happen".

Downloads

Basement floor plan

Other, Size 0 kb

Source

Building Sustainable Design

No comments yet