Just as vital was the construction management approach that maintained the pace of the project. The scale and nature of the Burj Al Arab project alone necessitated the appointment of 60 package contractors, of which six were solely involved with building services. One of the biggest challenges facing the contractors was managing the sheer volume of work on multiple work faces. Building services work alone amounted to more than 3000 man-years.

Before work could even start on building the hotel, it was essential to set up the services for the workforce. With 3 MVA of temporary site electrical distribution, a temporary high-rise water distribution system and a temporary drainage and sewage disposal system for the 4000 strong workforce – the temporary site services were a project in their own right.

Once work began on the hotel, there were other problems to be overcome as the project proceeded. Anticipating these problems and planning suitable solutions proved to be the key to success.

For example, the high specification finishes throughout the front of house areas meant that there was very little flexibility in the drywall/ceiling constructions. Consequently, the building services works had to be executed in four mechanical, electrical, plumbing fixes and two integrated extra low voltage fixes in conjunction with three different building package contractors. This required meticulous pre-planning and site control through strict office and site procedures. For instance, the 75 000 building services ceiling terminals were sited to within ±4mm of design with very few exceptions.

Throughout the project the sheer scale of the paperwork was astonishing. Building services contractors produced a total of 3000 working drawings, 1200 material submittals and 300 method statements. Allowing for changes and re-submissions, this meant that around 10 000 documents were submitted to and reviewed by W S Atkins.

Keeping up the comfort

Initially, the plans for the central area included an underground plantroom in front of the Jumeirah Beach hotel and putting water-cooled chillers in the basement of the Burj Al Arab, using seawater for cooling. Eventually these ideas were rejected in favour of a central plant area serving the entire resort, located just over 1 km from the Burj Al Arab and 500 m from the Jumeirah Beach. Providing a home for heating, cooling and water treatment plant, the compound also houses waste management services, as well as staff accommodation and the staff training school.

Most of the cooling at the two hotels and associated areas is supplied by 32 air cooled chillers with a total cooling capacity of 30 MW, providing some standby capacity over and above the 27 MW anticipated cooling demand. Primary chilled water pumps circulate about 1200 l/s of chilled water at 6°C to the two hotels, using two 600mm mains that run either side of the road. This duplication ensures continuity of supply in the event of one of the mains being damaged by road works in the future.

Each of the 600 mm mains splits into two, 500 mm mains, one serving the Jumeirah Beach and the other serving the Burj Al Arab. Chilled water is circulated to the top of the Jumeirah Beach but the height of the Burj Al Arab dictated a different approach.

Taking the water directly to the top of the hotel would have generated pressures of around 40 bar at the bottom, so three custom built stainless steel Alfa Laval heat exchangers, each the size of a small truck, are located on the 8th floor of the hotel. These act as interceptors to control the pressures, with two heat exchangers meeting the duty requirements and the third on permanent standby. A battery of smaller exchangers handles the needs of the low temperature hot water system.

Setpoint conditions for rooms in both the hotels are the same, at 23°C and 55% rh, though the Burj Al Arab has more sophisticated humidity control. Each suite is fitted with a mini air handler to achieve this, linked to the main Landis & Staefa bems, which monitors the conditions of each room and adjusts parameters accordingly. At the Jumeirah Beach, individual fan coils with electric heaters are used to control individual room temperatures.

A major concern for the air conditioning design, as you might expect, was solar gain – as both buildings are covered in glass.

To minimise the problem a low emissivity coating was applied to all of the glass. Glass with a U-value of 0·32 W/m2K was specified for the spandrel panels, with glass of 1·7 W/m2K on other areas. The total solar coefficient is 0·06.

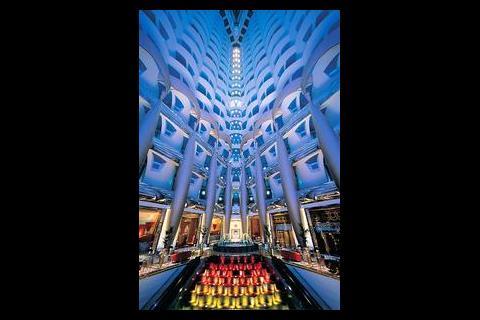

In the atrium of the Burj Al Arab, heat gains were estimated at 650 kW and thermal modelling was used to arrive at the necessary airflow rates to maintain an even temperature throughout. Under normal conditions, airflow is maintained at 100 m3/s, with the fan capacity to increase this to 350m3/s in the event of a need for smoke extraction. To achieve this there are 12 fans at level 17 and six fans at level 27.

In addition to the chillers, there are also six reverse cycle heat pumps at the central plant compound, used solely for the swimming pools in the Jumeirah Beach and for the Wild Wadi water park. These have 4 MW heating capacity and 3 MW cooling capacity, switching between heating and cooling automatically in response to the demands of the water park. Only five of the heat pumps are required to meet the loads, with one as standby, but the facilities managers tend to share the load between all six.

Most of the heating for the hotels is supplied through heat recovery from the chillers, with only occasional need for topping up by electric heaters. The greatest need for heat is for dehumidification and the heating demand for dehumidification in the summer exceeds that for space heating in the winter. This provides a very neat supply and demand pattern, with most heat being generated by the chillers during the summer months.

An 800m3 hot water tank at the central plant compound stores sufficient hot water to meet 50% of the demand from the various facilities. The remaining 50% is stored in supplementary storage tanks in the buildings.

Electricity supply

Electricity supplies are provided via a 100 MW, 132 kV sub-station, built by the local electricity authority, to meet the current 60 MW connected load as well as the future needs of the resort. This supplies 18 hv sub-stations located around the complex, including switchgear to link in two 1·8 MW standby generators in the central plant area. Six of the sub-stations, each with two transformers, serve the chillers.

Maintenance

High humidity, large temperature swings, a corrosive saline atmosphere and the constant ingress of sand, all combine to create an environment where high standards of maintenance are essential to the continued integrity of the plant. Paint peels from surfaces rapidly, and even the stainless steel structures corrode remarkably quickly – so all of the plant has a predicted lower life than in the UK.

The chillers, for example, are constantly exposed to the elements and need to be pressure washed every three months to remove sand. As a result, their design life is only 15 y, though the chances are they will last a little longer. In fact, none of the plant has a design life of over 50 y – and there would be little point if they did because that is as long as the buildings are expected to last.

Water supply

The Dubai Electricity and Water Authority desalination plant at Jebel Ali power station, about 15 km away, supplies water for the development and the surrounding area. Total demand design for potable water from the main for the development is about 2850 m³/day, which includes an irrigation requirement of 1316m³/day. There are plans that some 386m³ of the irrigation requirement will be met from treated sewage effluent, once the Dubai municipality has upgraded its sewage treatment systems.

Water from the desalination plant is distributed at almost 50°C and, during the summer, the network does not allow the water to cool. Consequently, each hotel has a separate distribution system for cooled water, serving guest rooms and changing rooms and making cool showers and baths possible. Water is cooled via a heat exchanger from the air conditioning chilled water system and then stored separately from water for general use and for hot water system make up.

All water for domestic use in the hotels in the hotels and associated buildings is treated at a common central plant at the plant compound, passing through sand and carbon filters before being part-softened and treated with chlorine dioxide. The decision to re-treat all water entering the resort was made because of the variable chlorine levels of the water from the mains and the danger of sand entering the distribution pipework in areas outside the resort.

The water is also dosed with a silica-based treatment to protect the copper pipework from pitting corrosion and pinhole leaks. Once ready for use, up to 3000 m³ of potable cold and filtered water, including that for irrigation, can be stored on site.

Foul drainage

Originally there were no plans for a municipal sewer network and the resort was to have included a sewage treatment plant on site. However, Dubai municipality eventually decided to extend its network ahead of the original programme and foul drainage from the resort is now carried from the site to the sewage treatment works at Al Awir, 40 km away.

At the Jumierah Beach hotel and the conference centre, the above ground floor foul drainage is discharged by gravity, but as the resort is at sea level, the invert of the sewer is high and most of the drainage has to be lifted to the sewer. Drainage from the Jumeirah Beach, sports centre and marina restaurant is lifted by sewage ejectors, while in the beach restaurant submersible pumps are used because of construction restraints.

Foul drainage at the Burj Al Arab is collected into a common holding tank in the third basement 10 m below sea level and discharged across the bridge by dry well pumps and then into the sewer. This system has 100% redundancy of tanks and pumps.

At the water park, foul drainage is lifted to the sewer by pumps at two locations. These pumps are fitted with a number of integral flush valves to scour the sumps prior to being emptied at each pumping cycle.

Storm water

Storm water is discharged to the sea by a combination of gravity drainage and lift pumps, making extensive use of sand traps and soakaways wherever possible. Local environmental regulations do not allow pool backwash to the sea so a diatomaceous earth filter, which requires less water for backwashing, is used at the hotel and Wild Wadi pools to reduce the fresh water demand and drainage load.

Ground water levels to the elevated gardens above the car park and changing areas in the Wild Wadi are controlled by a sub-soil drainage system. This is to remove excess irrigation water and rain water from the soil, which would otherwise load the structures below.

The Jumeirah Beach resort development has been described as an architect's dream and an engineer's nightmare.

It certainly provided a massive challenge to the resources of the building services engineers involved in the project – along with the satisfaction of meeting that challenge.

Source

Building Sustainable Design