The BBC Media Village in White City had to provide workers with a high quality environment to entice them from their West End offices. We report on how this has been achieved.

As the BBC looks to reshape its future under new leadership so too its building stock is undergoing rejuvenation. The new BBC Media Village in White City, which houses the Corporation’s playout and corporate operations, has enabled the BBC to begin to consolidate its numerous properties that are dotted around London. Ultimately the BBC aims to operate out of three principal London developments: the Media Village, Television Centre and Broadcasting House.

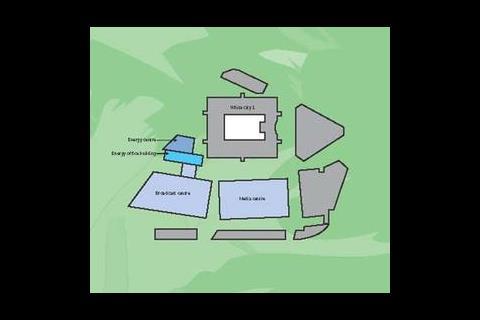

The Media Village development consists of three major buildings: the Broadcast Centre, which houses all the state-of-the-art digital equipment and playout suites from where television programmes are put out to air; the Media Centre, a flexible space; and the Energy Centre, which houses plant for the entire site.

Consulting engineer Buro Happold first became involved in the scheme in the late 1990s when it was approached by the BBC’s in-house architects to contribute to the design of a flexible media facility next to the existing White City One building. Neil Billett, partner at Buro Happold says: “It became a real project when the BBC understood that as well as needing to create this new centre, it was a key part of reorganising themselves because it gave them the swing space to move people from their other buildings in London when they came to refurbish them.”

The layout of the site was, as the name suggests, planned to create a village environment. The three main buildings all face on to a main ‘street’. The Energy Centre, being the non-office building of the three, is placed on the edge of the environment, sitting adjacent to the A40. Early wind and daylight modelling was conducted to make sure the street wouldn’t become too much of a wind tunnel and to make sure adequate daylight was admitted in between the buildings and that neighbouring properties weren’t adversely affected. This resulted in the gap between the energy and broadcast buildings being closed up, removing the corridor to the A40 that existed between them and creating a dead end for the wind to negate its impact on the site.

As the project grew BBC Property recognised the need to appoint an external architect to work alongside them, the ensuing architectural competition was won by Allies and Morrison. The BBC, having decided that they needed to partner with a firm for whom property was their core business, then entered into partnership with Land Securities Trillium, which meant a change in client focus for Buro Happold. “We had been working by that stage for two or three years with the mindset of an owner occupied building,” says Billett, “But now the BBC staff teams were going to be tenants and Land Sec Trillium wanted to impart a certain commercialism into the project. If the BBC ever moved out they didn’t want to be left with a space that was so bespoke to its technical needs that no one else would ever be interested in renting it.”

Client vision

Apart from the technical areas in the Broadcast Centre, the rest of the development took on a slightly more commercial base spec, but the picture was to change again when Land Sec Trillium appointed builder Bovis Lend Lease. Having three sets of stakeholders to present to made the design process a long and involved task, but one which ultimately led to a well tested, well interrogated set of solutions, as Greg Carpenter, associate at Buro Happold explains: “Three different clients, three different perspectives all sitting round the same table all wanting you to say a different thing led us into months of negotiation and contracts to get to the end result. The good thing is though, that the people we started with on the BBC property and technical departments have remained the same and they have always had a clear vision about what they wanted.”

The objectives of the BBC were firmed up into the 2020 vision, which acted as Buro Happold’s base brief. The vision set out a series of strategic goals and aspirations for the feel and quality of the space. One of the key factors was that the village had to be of a high enough quality to attract people used to working in the West End out to White City.

The other driver behind the strategy for the new site was that it needed to be able to adapt to advances in technology, and not fall foul of the same problems of other BBC buildings. The technical brief was developed with the BBC’s technical users to make sure the solution measured up to exactly what they would require. Carpenter says: “As time has developed the technology that goes into broadcasting has changed and it meant the BBC were stuffing old buildings full of brand new kit, putting layers and layers of cables on top of each other and ending up with buildings completely unusable for the modern day environment. In rethinking this process, they came to us with a very clear brief and said they want to be able to strip out and replace old kit. In previous buildings they’ve been concerned about stripping anything out because if they dislodge one wrong cable they could go off the air. The prime focus has always been that they must be on the air 24/7, and this underlines the whole brief for the Energy Centre and Broadcast Centre – total resilience in everything they do.”

Energy Centre and bte

Initial plans for the Energy Centre included the provision of chp units, but with the drawn out contractual process, it was felt that an energy agreement couldn’t be entered into at that early stage. Space planning in the Energy Centre has allowed for the installation of two 3 MW chp units at a later date. Carpenter says: “Instead of running these buildings individually, we wanted to consolidate our plant in one place. It allows us to generate and drop everything in in a structured way in the future and it clears up the space planning in the other buildings. It also means you can fit in much bigger co-located kit, which becomes far more efficient and easier to maintain and gives you resilience across the whole site rather than just one building.” The Energy Centre houses six package air cooled chillers each providing 1·2 MW of cooling. Another two chillers sit remotely on the Broadcast Centre as part of the site’s resilience strategy, as Carpenter explains: “The Broadcast Centre can run completely on its own but we can also run all the critical loads of the Broadcast Centre independently from the Energy Centre. This allows us to shunt water all round the site and if failures occur we can start culling buildings and bring the resilience back to the critical areas of the site.”

This concentration on resilience is most evident in the broadcast technical equipment (bte) area, home to rows and rows of computer equipment and miles of cable, all serving the playout areas directly above, from where the BBC airs its shows. This 1500 m2 floor stands at 1·8 times the height of the other floors in the Broadcast Centre to allow space for a mezzanine cable floor above the computer equipment. This gives the BBC the space they will require to strip out cable without fear of disrupting any critical feeds to the floor above. Carpenter says: “The mezzanine cable level is effectively a big walk through ceiling void. The cables can come up and dress onto the mezzanine and then go straight up into the playout suite. We can spread the cable out over the mezzanine, we can see which cables are going where and we won’t overburden the rest of the building by having to run them out sideways into risers and back in. We can run them straight into the areas where they are required.”

The rows of computer racks in the bte are arranged in a front-to-front, back-to-back configuration, each rack with the potential to draw up to 4 kW. “If they got that high you wouldn’t have enough space to get enough air through to cool them,” explains Carpenter. Cool air is supplied down the aisles as low as 11°C from vents at the end of the aisle which supply air into the space at 6-7 m/s. The air quickly mixes in the space giving an overall temperature up to 17°C-18°C. The air is sucked in by the individual fans on the equipment and then either discharged out of the top of the rack or back into the exhaust aisle before being drawn up through the cable deck space and is taken back into the cycle. Cables are kept clear of the areas above the exhaust aisles so as the mesh deck is more permeable for the hot air to rise through. Ducts take the exhaust air back along the sides of the room and down to the four ahus in the basement. This solution shaved considerable height off the building and provided a more adaptable and robust operational solution.

The whole of the bte space is fitted with a nitrogen gas fire suppression system. Carpenter says: “Because it was such a huge development, we looked at all the conventional ways of fire suppression. The environmentally friendly nature of the building led us to think about which gases have no contaminants, no CO2, no global warming effect. This will be the first large scale use of nitrogen as an inert gas suppression system probably anywhere in the world.” In the event of a fire, the room can be flooded with nitrogen through nozzles in the ceiling within 60 seconds. The gas can then be circulated indefinitely until operators choose to purge the room. The suppression system for the bte space can drop the oxygen level below 15% to avoid combustion but keep it above 11% to enable people to breathe. The system effectively allows two to three days for a problem to be rectified before the room would need to be purged, ensuring that the network doesn’t go off air.

Above the bte floor, level one can be divided into nine discrete spaces, to allow the BBC to let these areas out to other channels. The suites and the higher open plan office floors surround a dramatic atrium, notable for an array of brightly coloured acoustic baffles which have been designed to deaden the reverberant time in the atrium and provide acoustic attenuation between the open areas of the different floors.

BTE m&e

The electrical services to the BTE are designed to ensure the power is highly resilient. The electricity supply company has provided two independent 11 kV feeds to the site, from two different main switching stations and run on diverse routes. These feed two BBC 11 kV switchrooms, in the Energy Centre.

The essential loads are fed from four substations, on an 11 kV ring which can be fed by either of these BBC switchrooms. The BBC 11 kV switchboard is set up so the essential ring can be fed from either of the electricity board supplies or from the future chp generators (should these be installed), via either BBC switchroom.

The four essential services substations each feed a 1 MW rotary ups unit. Each of these rotary ups units is designed to transfer the load to a diesel generator should the mains fail. Half the load transfers with no interruption, sustained by the generator flywheel until the diesel motor takes up the load. This is the critical supply. The other half of the load, the essential load, experiences a brief interruption to the supply in the transfer from mains to generator. Should the rotary ups fail then the critical supply has an additional standby power supply – a battery powered static ups.

The critical loads are fed via power distribution units (pdus) – each of which is fed from two different critical supplies, with automatic, uninterrupted transfer, to the standby supply should the duty supply fail. On top of that each of the critical loads has supplies from two different pdus, and is designed to operate on either. As long as three out of the four Critical supplies are live all the critical loads will be supplied and the most critical loads will stay live as long as any one of the critical supplies is working. So the broadcasting of Eastenders is safe unless both electricity board supplies, three out of four generators and three out of four static ups’ all fail!

Broadcast and Media Centres

The other floors of the Broadcast Centre are given over to production and design departments where the more acoustically sensitive activities are carried out. There are also some cellular offices for meetings. Modern technology has allowed for much editing to be done from the desktop, and with the extra equipment that this brings, heat loads around these desk areas are much higher than in a conventional office space. Active chilled beams are used here to provide high comfort levels and to free up floor void space, maximising data cable volume and low cost, quick-churn re-cabling and repartitioning, all part of the flexibility theme.

Much attention was paid to the strategy of how to deal with solar gain in perimeter spaces. CFD modelling was undertaken to achieve the required comfort at the same time as ensuring the suspended ceiling stops 1·5 m short of the facade in accordance with the 2020 vision of a light, airy environment.

The Media Centre, a much more conventional office space, uses high volume upflow ventilation. The problem of perimeter solar heat gain in this building is dealt with by the use of passive chilled beams within the ceiling void, once again in compliance with the original 2020 brief. Electrical services for the office spaces are mostly conventional, with Electrak power track in the floor void connected to floor boxes and prefabricated wiring in the ceiling voids to lighting control modules. Lighting control is more sophisticated with individual control of each light via a Symtronic control system.

The Media Village has achieved BREEAM ratings of excellent for both the design and construction stages of the development. Buro Happold’s sustainable engineering department was separately commissioned to ensure that targets set at design stage were met. Billett says: “Their appointment was continued to act as a kind of policeman throughout the project to make sure we weren’t going off beat and also to make sure what was being built was what had been designed.”

The Buro Happold team moved on to site during construction to make sure that the project was being delivered as they had intended, which was a hard task with the shifting client focus they had to deal with. Billett says though, that that period of the job was a positive thing for the quality of the end product: “When Land Sec Trillium came on board we were tested very specifically on how our design would respond to a whole set of different questions that hadn’t previously been asked. It was a good test to see if the strategies, particularly the chilled beam solution would work.”

The perimeter buildings on the Media Village site could potentially be let out to smaller media companies looking to sample some of the BBC culture and hope for some of it to rub off on their own operations. If the success with which the project has been delivered is mirrored in the quality of the services its users provide there will be plenty of good feeling to go round.

BBC Media Village, White City, London

Mechanical suppliers

AHUs Holland Heating /Carrier

Diffusers and grilles Trox/Gilberts:

Boilers Welman Robey

Burners GP Burners

Passive and active chilled beams Trox

Chillers Trane R134a Air cooled chillers

Control valves Siemens Automative/Samson/Bray

Computer room a/c Denco Down Flow Units

Ductwork Galloways, Fire Protection

Extract fans Nuaire/Woods/FlaktWoods

Expansion bellows Engineering Appliances

Fan coil units Diffusion

Gas boosters Nu-way

Heat exchangers Alfa Laval

Hot water calorifiers IMI Rycroft

Humidifiers JS Humidifiers supplies as part of Holland

Insulation system, pipework Kooltherm/Vicutube/Mineral Wool/Armaflex/NMC Tube

Pumps Holden & Brooke (general), Selwood pumps(oil), SPP (fire), Camak Pumps (underfloor), New Haden Pumps (sump)

Pressurisation Holden & Brooks

Radiators Hudevad

Raised floors Atlas

Sound attenuation Caice Attenuation/Hotchiss Air Accessories

Toilet extract fans Woods:

Underfloor heating Warma Floor

Valves Holmes

Water boosters Holden & Brooke

Water heaters Sadia Instantanous

Electrical suppliers

BEMS Siemens Building Automation

CCTV Gratte Brothers

Controls Siemens Building Automation

Electrical distribution ABB/Sophire switch gear

Fire alarm/detection Cerberus (Siemens)

Floor boxes Electrak

HV switchgear ABB

Lifts Otis

Luminaires Wila and DAL

LV switchgear ABB

Motor control centres Siemens/Hartley & Dark

Power busbar Barduct

Public address Siemens Cerberus

Standby generation Cummins & Pillar

Trace heating Process Heating

Underfloor heating Warma Floor

UPS Anton Piller

Engineering data

Gross floor area 40 491 m2 (Broadcast Centre); 39 014 m2 (Media centre); 7 719 m2 (Energy Centre)

Structural details

Slab thickness 450 mm

Floor to ceiling 2800 mm

Ceiling zone 550 mm, 450 mm clear

Net services zone 800mm

Live load 4·5 kN/m2 (+ 1·0 for partitions)

Dead load 1·0 kN/m2 (excl partitions and self-weight)

External design conditions

Winter -4 °C/Sat

Summer (a/c) 29°C db, 20°C wb

Internal design conditions – Broadcast centre

General office/meeting/technical areas 21°C +/- 2°C (winter); 22°C +/- 2°C (summer); 35-65% rh

IT Server &PABX room 19·5°C +/- 2°C (winter); 19·5°C +/- 2°C (summer); 35-65% rh

Toilets lobbies & staircase 17°C min, rh uncontrolled

Atria Temperature and rh uncontrolled

Internal design conditions – Media centre

General office/meeting/technical areas 21°C +/- 2°C (winter); 25°C +/- 2°C (summer); 35-65% rh

IT Server and PABX room 19·5°C +/- 2°C (winter); 19·5°C +/- 2°C (summer); 35-65% rh

Toilets lobbies & staircase 17°C min (winter); uncontrolled (summer); rh uncontrolled

Atria Temperature and rh uncontrolled

Occupancy – Broadcast and Media Centres

Offices (open-plan) 1 person/8-10 m2

Meeting rooms 1 person/2·25-5 m2

Playout/Technical 1 person/2·25-5 m2

Noise levels

Offices NR 40; toilet & circulation NR 45; external breakout limits 55dB(A) at site boundary

Target energy use

Information withheld

BREEAM Excellent

Loads

Installed heating load 7·5 MW nominal

Installed cooling load 10 MW nominal

Base design loading for Broadcast and Media CentresEquipment/Power 30 W/m2 (open-plan); 40 W/m2 (cellular/enhamced)

Lighting 12 W/m2 (open-plan); 15 W/m2 (cellular/enhanced)

Occupancy 10 W/m2 (open-plan); 20 W/m2 (cellular/enhanced)

Fresh air 12 litres/s per person (open-plan); 8 litres/s per person (cellular/enhanced)

Ventilation, scheduled supply air temp 14/20°C (Broadcast Centre); 19°C (Media Centre)

Distribution circuits

LTHW (primary) 90°C flow, 70°C return

LTHW (secondary): 80 °C flow, 69°C return

CHW (primary) 6°C flow, 12°C return

CHW (secondary) 7°C flow, 13°C return

CHW (Media Centre, passive chilled beam) 14°C flow, 17·5°C return

CHW (Broadcast Centre, active and passive chilled beam) 14°C flow, 17°C return

DHWS 60°C flow (traced heated)

Chillers Six 1245 kW (nominal) air cooled chiller (Energy Centre); two 1250 kW (nominal) air cooled chiller (Broadcast Centre)

Boilers Three 2500 kW natural gas fired boilers (Energy Centre); space allocation for future chp (Energy Centre)

Electrical supply

Two 11kV supply – 17 MVA from 24 Seven Network

Standby 11 kV supply – 8MVA

Transformers Six 1·5 MVA/2·2 MVA (Energy Centre); six 1·5 MVA/2·2 MVA (Broadcast Centre); two 1·5 MVA/2·2 MVA (Media Centre)

UPS system Four 1100kVA (Broadcast Centre)

Standby power 1200 kW (Energy Centre); Four 2200 kVA (Broadcast Centre); 1200 kW (Media Centre)

Lighting

Offices 350-400 lux; glare index 19

Toilets, stairs, circulation areas 150 lux; glare index 22

IT server room 400 lux

Plant rooms 200 lux; glare index 25

Costs

Information withheld

Source

Building Sustainable Design

Credits

Client

BBC Property and Land Securties Trillium Partnership

Project manager

Gleeds Management Services

Main Contractor

Bovis Lend Lease

Architect

Allies & Morrison

M&E engineer

Buro Happold

Structural engineer

Buro Happold

Civil consulting engineer

Buro Happold

Quantity surveyor

Gleeds

M&E contractor

Haden Young, ABB (mechanical); T Clarke (electical)

Commissioning contractor

JPS

No comments yet