When this has to be achieved inside a Grade II listed building where space is at a premium, the job becomes much more complex. These were the challenges faced by consulting engineer Gifford when it was appointed to work on the phase one refurbishment of the Great Hall at Lincoln's Inn in central London.

Situated just behind Chancery Lane, the Inn is the oldest of the four Inns of Court where newly qualified barristers are called to the Bar. The Great hall was opened in 1845 to relieve the burden placed on the Old Hall by the Inn's functions. It is used for dining during the law students' term times and provides lunch for its members throughout the year, so a well equipped modern kitchen is key to the operation of the venue.

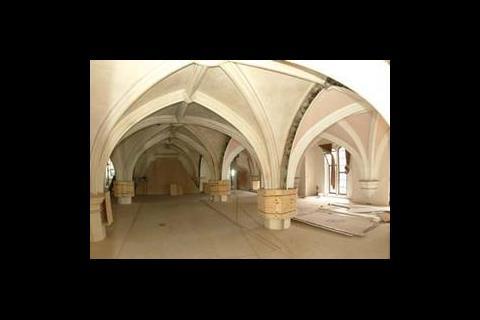

Deputy estates manager Chris Bell from the Inn says: "Dining is an important function of the Inn and the Great hall is used every day for lunch for the judiciary, members of the Inn and the bench. The hall is often also used in the evenings for formal functions." The first phase of the refurbishment programme encompasses the kitchen, its ancillary areas such as glass, pan and dishwashing rooms, and some offices. Senior mechanical engineer Mark Smith is leading the project for Gifford: "The Inn is looking for a high-spec modern kitchen. The old kitchen was a double height space with a vaulted ceiling, so part of scheme involved installing a mezzanine floor to create a new Bar common room above the kitchen which can be used as a pre-dinner reception room in the evening and for special events."

As with many historic buildings, no original drawings of the services existed, and there were lots of unknowns to contend with as work began. Smith says: "Services in older buildings tend to be added to over the years and the redundant services are often left in position and the Great Hall was no exception. This is usually done to avoid the disruption which stripping out can cause, so surveying has been a major part of the project not only for the consultants but also for the contractors as well."

Location of plant

One of the biggest challenges facing the design team was the lack of space to site air treatment plant – apart from a small service yard to the west of the building, all the other facades are open to the public. "A ventilated ceiling is being installed in the kitchen, rather than hoods, and needs plant to supply it with fresh air and treat the extract to remove cooking smells," explains Smith. The kitchen is located at basement level and a bin store in the service yard has had to be knocked down to make a plant room for extract and supply air handling units.

The Great Hall is used for dining and lunch for its members throughout the year, so a well equipped modern kitchen is key to the operations of the venue.

The building's listed status meant any penetrations in the building had to be made through windows rather than brick. A kitchen specialist was on board from the beginning of the project and has been integral, says Smith, in the design of the ventilation solution. "The extract we are looking at for the kitchen itself is 8·8 m3/s and the supply is 8·1 m3/s. We worked out that we could do it with one extract fan, but we didn't have enough plant space in the service yard to put in one supply air handling unit large enough to supply the whole kitchen, so we had to split it between five separate units, strategically placed around the building."

Noise issues also came into play on the project. "The fan needed for a 8·8 m3/s extract generates just over 90 dB – equivalent to standing by a lawnmower." The design team had to satisfy the local authority that the new extract would not impact on the surrounding area. "We've used a lot of ductwork attenuation and specially designed acoustic louvres on the plant room to do this," says Smith.

Supply air will be brought through the plant room's double banked 540 mm thick acoustic louvres. There are two windows through which a supply and extract duct will each run. Smith says: "On the supply, we have had to use more than one silencer because we couldn't physically get a big enough silencer into the plant room to serve the whole kitchen, so we have had to break it down and have a silencer coming off the fan and then separate silencers for each supply leg." A smaller duct also splits off the supply leg to service the pastry room, with a cooling coil installed to bring the air down to around 12°C which will cool the air in the space to the required 20°C to prevent the pastry from spoiling.

The smell of the extract air was also an issue that Smith says had to be dealt with: "We have a ultraviolet system which works by mineralising the grease and removing odours. The air then passes through a pre-filter, that takes out the dust formed by the mineralisation, followed by a carbon filter to remove other cooking smells."

The pan wash, dish wash and glass wash rooms, all located in the south basement area, also presented a problem with air discharge, as Smith explains: "On the south side we have a terrace which is used as an entrance area to the building, so we had to treat the extract air with carbon filters so we don't get any detergent smells."

Controls

The ventilation system is controlled by variable speed drives on the main air handling plant and the extract. The system is operated by a simple switch, similar to a light switch, which when activated will run the system at 40%. "The chef has overriding control of the space," says Smith, "however the system also has an automatic temperature control, so if the temperature rises above a certain level the system's power will increase. This helps save energy during quieter periods but ensures the optimum cooking conditions when the kitchen is busy."

The pastry section is operated by the same system, but the pastry chef will have a separate controller. The system also shuts off automatically if it is accidentally left on overnight or at the weekend but the system is fitted a night time set back to control the temperature to a minimum of 10°C. "This will protect the internal finishes from condensation and maintain the condition of the ceiling," explains Smith.

Source

Building Sustainable Design

No comments yet