The findings, published in Building Services Journal (p 7, February 2002), illustrate a worrying trend that has seen building maintenance costs balloon in the last couple of years. These figures reflect the ever increasing budgets being sanctioned to ensure that building services operate with as little disruption to a building's occupants as possible. Indeed, with increased legislative pressures and heightened productivity targets, this emphasis on trouble-free service provision is well founded.

Law and order

Traditionally, building services has encompassed the provision of fundamental utilities such as lighting, electricity and heating. However, as the demands for building services have become more complex, so the legislation covering them has mushroomed.

Nowadays, if an extraction fan in an underground car park fails, the repercussions could lead to serious customer and staff disruptions, as health and safety officers will be forced to close the facility if the build-up of fumes exceeds specified safety limits.

The same regulations can come into force if a cooling system in a large restaurant's kitchen fails, or an environment system in a data centre breaks down leading to operational disruptions and potential profit losses.

The Workplace (Health, Safety and Welfare) Regulations 1992 stipulate that, during working hours, 'the temperature in all workplaces inside buildings shall be reasonable'. The Regulations go on to state that 'An acceptable zone of thermal comfort… lies roughly between 13°C and 30°C.' Although a maximum temperature is not expressed, working conditions outside those stipulated – brought about by a malfunctioning air conditioning system, for example – will result in a failure to meet heath and safety criteria.

As a result, air conditioning, extraction and cooling system failures can not only lead to disruption in terms of productivity and, consequently, profit, they can also lead to health and safety violations and possible legal action.

Condition critical

Safeguarding utilities against failure is therefore an increasingly important role that the building services manager has to incorporate into their budgetary considerations. One of the most cost-effective methods of doing this is by adopting a conditioning-monitoring policy, which identifies potential failures and encourages more efficient maintenance regimes. In this way, conditioning monitoring can be used to anticipate key component failures and co-ordinate just-in-time maintenance policies.

Conditioning monitoring involves the collection and assessment of data from building services systems, which can be used to establish an effective preventative, predictive and/or proactive maintenance policy. More specifically, vibration monitoring is generally regarded as a cost-effective cornerstone on which such initiatives rest, although other technologies such as thermal imaging, oil debris, temperature and sound analysis are also available.

By measuring vibration, building service managers can assess operational changes in the condition of rotating machinery – including ahus, pumps, fans and chillers – brought about, for example, by machine imbalances and bearing degradation.

The principle of vibration monitoring is particularly suited to assessing utility provision due to the heavy reliance on components that rotate and therefore become unbalanced when suffering from wear or unexpected stress or deflection.

Monitoring the situation

There are two main derivatives of vibration monitoring equipment: those which supply continuous, permanent monitoring; and those which are hand-held and mobile.

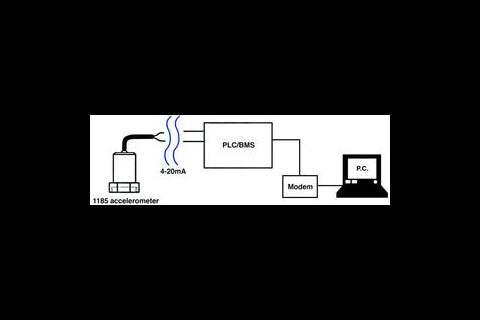

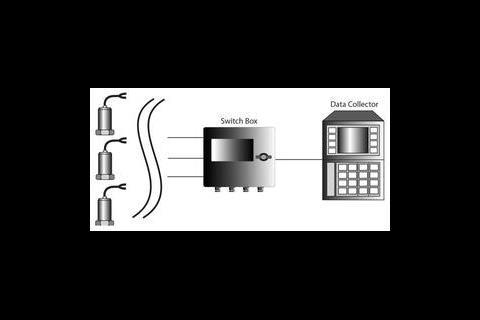

For critical applications, accelerometers can be connected via a bems to a pc for real-time data monitoring and analysis. Off-line data collectors are more often used where analysis or monitoring doesn't need to be real-time.

Both types of monitoring are typically based on piezoelectric technology and utilise a measuring element constructed of either synthetic piezoelectric ceramics or quartz.

The sensor produces a signal that is directly proportional to acceleration and can be amplified for acceleration measurements, or electronically integrated within the sensor into a velocity or displacement signal. Available in a variety of designs, piezoelectric accelerometers are easy to use and install. Consequently, these low-cost devices are ideal for a wide range of applications due to their solid-state design which is unaffected by dirt, oil and moisture.

Permanent location

Vibration sensors can be permanently fixed to key systems to provide a continuous data stream. This can be fed back via a conventional 4-20 mA output for broadband monitoring or via an ac output for full frequency analysis. Standard data processing equipment can then be used to compare the information gathered against previous vibration trends.

Since permanently fixed sensors are able to supply a continuous output signal that can be hard-wired back to switch boxes and then on to processing units located in central control centres, manual intervention is not required during the measuring process. This arrangement means that diagnostics collected by the sensors are extremely accurate as they are collated from the same location on every occasion. Error readings are therefore eliminated, providing even higher levels of accuracy and repeatability.

On the move

Although most manufacturers supply fixed monitoring solutions, more recently, all-in-one sensors have also been developed to provide a quick and easy method of collecting vibration data to immediately assess equipment performance.

These systems can feature a truly mobile metering system that can be used on routine inspections around the building. Vibration level readings can subsequently be used to plan effectively for remedial repair of component replacement.

These all-in-one systems, featuring built-in displays and portable vibration metering kits can provide a complete solution from a single location. These instruments are particularly useful in hard-to-reach places or where building managers have only just embarked on a predictive maintenance scheme.

Bridging the gap

The pressures brought about by increased operational spending and the demand for more complex but also reliable service provision can be immense. However, vibration monitoring systems provide a cost-effective method of bridging the gap between these often opposing requirements by identifying and mitigating system failures before they happen.

Source

Building Sustainable Design

Postscript

For further information contact Suzanne Pearl, Monitran Ltd, Monitor House, Hazlemere Road, Penn, Bucks, HP10 8AD. Tel: 01494 816569. Fax: 01494 812256. E-mail: info@monitran.co.uk or visit: www.monitran.co.uk.

No comments yet