Ireland’s National Maritime College is not only one of a handful of such high-tech facilities in the world, it is also more energy efficient than your average office. And on top of that, it’s a PPP project. We find out how it’s all possible

Ireland may have just got in on the public-private partnership trend started across the Irish Sea but that hasn’t dampened its pioneering spirit. So rather than believe the popular wisdom that alternative procurement methods discourage sustainable design, the Irish government made energy-efficiency a key driver for one of its first education sector PPP projects.

As a result, the recently completed National Maritime College project in Cork, south-west Ireland, presented a particular challenge for the engineers at Building Design Partnership. Procured by the Irish Department of Education and Science, the scheme provides education and training facilities for the Cork Institute of Technology and the non-military requirements of the Irish Naval Service (see box: “The partners behind the NMC”).

This is no conventional college: courses range from a certificate of proficiency for deckhands to a masters degree in nautical science. As well as classrooms, labs, computer suites and a library, the college also has a broad range of specialist facilities for hands-on training, including state-of-the-art simulators for teaching navigation skills.

“The Department [of Education and Science] was the driving force behind the project and the issue of energy efficiency was high on the agenda,” Paul Niblock, building services director at BDP, explains. In its tender document, the department set a demanding energy target of 112 kWh/m2/y and under the PPP agreement, Focus Education, the shortlisted consortium, had to accept the risk on the volume of energy consumed by the building in the first 25 years. With nothing better to go on, the brief cited the Energy Consumption Guide 19‘s best practice figures for a naturally ventilated office. But as Niblock says: “This is not an office block and when you look at the kit that had to go into this building it is quite a difficult target to achieve.”

BDP’s view was that if there was any chance of meeting these figures, it first had to look at the areas in the building in which it could outperform the targets to compensate for the higher use zones. “The first step was to optimise the structure and our second line of attack was to look at the engineering systems,” says Niblock.

Being on board at the bid stage was a big advantage for BDP, allowing the services design to influence the way the building was configured, the availability of natural ventilation and daylight and also the envelope’s thermal performance. To this end the building has been split into three distinct blocks linked by a lateral three-storey circulation route: to the east is the facilities block, in the centre is the simulator block and to the west is the engineering block.

Detailed studies on the building’s energy use were carried out during the design to ensure that it met the energy targets set down in the brief. “The calculation of the energy usage over 25 years is quite complex because it has to be very accurate, particularly as the developer is putting its money behind it,” says Chris Croly, building services engineering associate at BDP, who undertook the environmental modelling of the scheme. “Through the simulations we demonstrated that the energy requirements for the most part could be met.”

Optimising the structure

Of the three blocks, the central simulator block was the most demanding for the design team. Here two state-of-the-art ship simulators are installed (see box “Welcome aboard”) in a large drum-shaped structure, along with a series of ancillary simulators. The design team knew there would be large heat gains from the PC-based systems, projector and electrical equipment. And with most of the simulators requiring total blackout, it was decided to house these in an inner block, flanked by rooms with lighter loads, such as classrooms and labs, which use natural ventilation and daylight.

The simulator block has been designed to make good use of thermal mass. The installation of suspended ceilings has been avoided to expose the structure, with services carried through a raised floor void, which provides an unobtrusive means of distributing the extensive power and data cabling for the simulators.

The simulator rooms are mechanically ventilated and cooled by a displacement ventilation system – air is supplied through the raised floor void and extracted at high level. “This system was chosen as it takes advantage of the increased floor to ceiling heights in the simulator rooms to permit stratification, thus maintaining comfortable conditions in the occupied zone below 2 m,” says Croly. So although the projectors have a large heat load, they are located at a high level in the room and the heat they generate is immediately removed from the room by the displacement strategy.

The classroom and laboratories also have exposed concrete ceiling soffits: pre-cast, profiled troughs were used with deep recesses to maximise the area available for passive heat absorption. Natural stack-assisted ventilation is provided by allowing air to transfer from the perimeter windows through openable clearstory windows to the corridors, where it rises in a natural ventilation shaft. This will permit a high degree of computerisation of the classrooms if required in the future, without the need for mechanical cooling or ventilation.

With the exception of the lighweight roof, the facilities block, on the east side, uses a heavyweight construction similar to the simulator block. The learning resource centre on the second floor is a largely computer-based workspace, but despite this it is entirely naturally ventilated and passively cooled. Fresh air is drawn in through motorised grilles at low level and tempered by passing through a void containing the space radiators. Air exits through an outlet at the top of the library stack. The inlet and outlet dampers are controlled together on the internal temperature.

A number of computer rooms are located next to the library. Their positioning enables them to draw air through from the double-height library, removing the need for any mechanical ventilation. All classrooms and computer rooms are provided with exposed soffits that moderate the internal temperatures and form part of the building’s night-cooling strategy. Here the windows have motorised actuators, controlled by room temperature sensors with local over-ride switches to allow users to maintain a comfortable environment.

Because of the nature of the facilities, BDP was able to take a much simpler approach to the engineering block on the west side of the building. A lightweight, steel-frame structure has been used and is predominantly naturally ventilated. And gas-fired radiant heaters overcome the problem of the large volume of the spaces and the ventilation losses from the provision of make-up air for engines.

Engineering systems

A number of measures were taken to optimise the engineering systems within the building. While some – such as using waste heat from the ship engine used for training students – fell by the wayside, others stood up to scrutiny.

Space heating is provided by two fully condensing boilers fitted with direct weather compensation control. To enable these to operate in condensing mode for longer periods the wet heating system has been designed to operate at a reduced temperature. Unlike a traditional heating system, which produces water at 82°C and then reduces this water temperature through a mixing valve to meet the load depending on the outside temperatures, the system installed at the college will generate water at around 50°C. “The efficiency of a boiler increases as its temperature reduces and controlling the heating water temperature with the boiler instead of the mixing valve can considerably improve the heating system efficiency,” says Croly. It is predicted that this could save up to 10% in heat energy.

To take further advantage of this strategy, the building’s radiators are slightly oversized to reduce the required water temperatures and increase the time for which the boilers operate in condensing mode. Domestic hot water is supplied from local gas-fired hot water generators in each block to reduce distribution losses.

The initial scheme considered the installation of cold and hot water loops around the building to enable a heat pump to be used to transfer the heat rejected from the simulators to other areas of the building where it was needed. However, the need for mechanical cooling in the simulators during the heating season was reduced through the use of displacement ventilation, and it was established that such a system would not be economically viable.

“Features such as heat pumps are often placed in buildings to produce an image of sustainability,” says Croly. “We aimed to reduce the loads through careful building design before the application of technology based solutions.” In fact, advanced energy saving measures can actually become uneconomical once loads are minimised. And with the developer requiring a full cost justification for all design options, this option was quickly dismissed. Perhaps this shows that the Irish government really has found a way to combine the PPP approach with environmentally responsible design.

The partners behind the college

The £36m National Maritime College is one of the few education schemes in Ireland to be built under a PPP. Getting the scheme off the ground called for a partnering arrangement between the Irish Naval Service and the Cork Institute of Technology. Both had previously relied on antiquated facilities and had found it difficult to make a business case for the substantial upgrades they required. However, by joining forces the two organisations were able to exploit the economies of scale that came with the provision for 750 students.

The new college was subject to a bidding process by three potential providers. Focus Education, a joint venture between Bovis Lend Lease and Bank of Scotland Corporate Banking, was selected as the preferred bidder and undertook the financing, design and construction of the college. It will also be responsible for its maintenance over the next 25 years and accepts the risk on the building’s energy consumption for this period.

Between 8am and 5.30pm Monday to Friday (8am to 10pm for the library and IT labs) the navy and the institute buy availability of the building, sharing the facilities using a simple booking system. Outside that time, Focus will sell spare capacity to third parties and split the profit with the other organisations. The big money will be made by hiring out the simulator facilities to other maritime organisations, but areas such as the gym and the training pool will also be made available.

Bovis Lend Lease is responsible for the construction and facilities management, with Bank of Scotland Corporate Banking handling the equity and finance aspects of the project. BDP provided m&e, structural, civil and architectural design services.

Welcome aboard

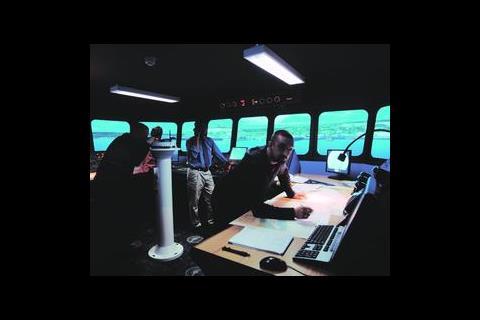

There are probably only half a dozen one-stop maritime training facilities like this in the world. At the heart of the college are the two state-of-the-art simulators. These are mock-ups of actual ship bridges with either 360° or 270° projection screens on which the main waterways and harbours of the world – from the Dover Straits to Sydney Harbour – can be simulated. While the bridges don’t move, the images on the screens sway to reproduce the natural motion of up to 12 Navy or 20 merchant vessels, and different weather conditions can also be created.

The simulators use WIndows-based software, with 16 networked PCs spread throughout the space. In addition to these there are a number of ancillary simulators, including an engine room. Realistic noise conditions are recreated in the space, where students can experience real engine room faults. Radio communication and radar simulators are also provided, linked to a full radar and comms antennae system mounted on the roof of the block. What’s more, all the simulators can be linked together for a complete exercise.

The maritime training college also has a 5 m deep survival training pool, along with helicopter test rig. A range of weather conditions can be created with a wave generator, rain simulator and large fans.

Several heavy engineering workshops provide welding rooms, machine rooms, electrical motor test rigs and an engine room, which replicates the propulsion and ancillary systems on board a ship.

A fire and flood training rig has also been built. The flood test rig comprises an enclosed ship hull that is flooded as students fight to hold back the water using timber off-cuts. The fire and smoke test rig simulates the conditions of a real on-board fire.

Source

Building Sustainable Design

No comments yet