As an exhibition to celebrate the development of the earth's surface and regions, the Dynamic Earth Exhibition is aptly positioned. Housed in the Sir Michael Hopkins designed William Younger Centre in the shadow of Arthur's Seat, the surrounding area is rife with evidence of plate tectonics and geological movements. The city's castle, less than a mile away, sits on a dormant volcano.

On entering the Polar Region through double sealed doors from the adjoining 'submarine', visitors are confronted by a sudden lowering of temperature and a 1·5 m3 mass of ice jutting from the floor.

Several ideas were toyed with before the design was finalised, including the use of a refrigerated meat transporter. This was discarded mainly due to the lack of control that would have existed over the growth of the structure.

It was initially thought that, to keep the ice frozen, a mix of cold pipework and continuous cold air would be required. The specialist contractor, Star Refrigeration, however, had vast experience of ice-rink construction and calculated that the pipework would be enough to hold the surface temperature at the required 4°C.

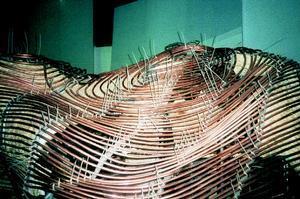

The final design consists of a hollow structure with an internal stainless steel frame covered in a network of copper piping. Glycol at -15°C is fed through this pipework, around which the ice forms.

The internal frame was constructed off site and supplied in two parts. Joined in the exhibition room, it was then covered with 1 km of carefully positioned 12 mm copper piping.

Copper was chosen for its heat transfer properties, ease of moulding and ability to keep its form. The sculpture has been based on 'real' icebergs and the designers were keen to recreate the intricate shapes found in nature. Larger diameter plastics pipe would have constricted this design. The pipework would have required connecting at many more points and would be less likely to maintain the shape designed when the ice formed. After a quarter-sized prototype was built and run, the engineers were reassured that transparent pipework was not necessary.

Due to the small diameters required for the design, bending machines could not be used. Instead, all 1 km of copper piping was bent over the knees of two Star Refrigeration plumbers. The sharpest edges were created by welding triangular copper plates to the pipework – the transfer of energy flowing from the pipe into the plate and ice forming at his point. The installation of this and all services pipework took only six weeks.

The iceberg was grown naturally, the glycol-filled pipes freezing latent moisture in the surrounding air. At full growth, the external depth of the ice will be 30 mm. From switching on to full growth, the creation of the iceberg was expected to take around two weeks.

The depth of ice inside the structure, at 10-15 mm, is limited by air circulation. The ice stops a few centimetres from the floor – not high enough to induce major circulation under the iceberg. The external depth is limited by the transfer of energy from the glycol.

The entire structure sits on an emergency drainage tray. No standby generation has been provided as the mass of ice is great enough to sustain itself for several days – enough time for an emergency supply to be connected should the mains supply still be down.

Periphery lighting is supplied by 12 x 13 W fluorescent lights with a blue colour filter. These are positioned slightly underneath the sculpture so, as the ice grows, the light will shine through it as well as onto it.

Setpoint conditions for the Polar Region are 15°C, 50% rh. The main variable in the system is the visitors and the effects their reactions to the display will have on the air movements in the room. Computer modelling was considered unrealistic enough to allow for groups of excited children running around and touching the sculpture, the air movements created affecting formation and melting of ice.

To minimise initial contact with visitors, hence possible condensation, supply air is introduced at floor level around the periphery of the room. The intention is for it to flow upwards, 'sticking' to the walls. A heated mat embedded in the ceiling of the room is another 'just in case' addition.

Careful control is required to ensure the ice will remain frozen and not fur up. The room has a separate system with standard temperature and humidity sensors. This is tied into the full Johnson Controls bems.

Maintenance of the structure is dependent on the reactions of visitors to it. The designers and engineers fully expect, and indeed intend, it to be a hands-on experience with people touching and sitting on it. They even expect name-carving to take place and are actually excited about what would normally be taken as vandalism. They see this instead as the sculpture having a life of its own. Minor maintenance to wear and tear of this kind can be carried out by brief melting with a hairdryer.

The Polar Region is only part of the Dynamic Earth exhibition. Other features include a rainforest, complete with tropical thunder rainstorms. The whole exhibition is an interactive learning experience, but with so much fun you'd hardly notice.

After months of preparation and design work, the last commissioning to be carried out before the public arrived was, what the engineers have named the 'tongue-test'. One of them had to lick the ice to ensure that if a curious youngster decided to, the sculpture wouldn't become 'iceberg with stuck child'.

Downloads

Arctic Edinburgh

Other, Size 0 kb

Source

Building Sustainable Design