Construction still accounts for around a third of all waste sent to landfill, not to mention its broader carbon emissions. How can the industry step up and develop a better approach to buildings’ end-of-life stage? Turner & Townsend Alinea explain the challenges and opportunities, and set out a typical on-site process

01 / Introduction

The key principles of the circular economy, as set out by the UK Green Building Council in 2019, include maximising reuse and minimising impact and waste. The principles of a circular economy are becoming increasingly embedded in the built environment, with new buildings incorporating recycled materials and components to lower the embodied carbon content of a building and make responsible use of finite resources. However, this raises some questions: where do recycled construction materials come from, and how can the main components of a building be recycled at the end of its life?

02 / The construction waste problem

At the end of a building’s life, construction waste presents a significant challenge. The Department for Environment, Food and Rural Affairs (DEFRA) found that activities in construction demolition and excavation (including dredging) create about 60% of the UK’s total waste. A further study by DEFRA revealed that construction is responsible for 32% of all waste sent to landfill, generally at a cost for transportation and disposal.

The Global Alliance for Buildings and Construction (GlobalABC) was founded at the COP21 conference of parties to the UN Framework Convention on Climate Change, and is a global platform for stakeholders in the built environment who are committed to a common vision of a zero-emissions, efficient and resilient sector. GlobalABC estimates that construction activities account for 39% of all carbon emissions globally. While most of this stems from energy used during building operation, a proportion is due to the extraction of raw materials. For example, the production of new steel is estimated to have produced 8% of global CO2 in 2020, producing CO2 at the mining, reduction and smelting stages.

>>>Also read: Cost model: Incorporating sustainability in purpose-built student accommodation

>>>Also read: How hard is it to decarbonise the construction of new homes?

The scale of the challenge is clear, and in recent years the industry has moved away from a linear model which limits end-of-life options to demolition to a broader view that considers how to use the embodied value of a building across a longer timescale.

The environmental value of buildings, components and materials is increasingly being legislated for, with the increased adoption of “reuse first” planning policies encouraging a shift away from demolition.

The complete demolition of a building often means that, for many elements of a building, the energy, carbon and effort that went into the extraction and manufacture of the original materials are wasted. The RICS estimates that 35% of a building’s whole-life carbon is accounted for before the building is occupied.

While there is a preference for entire reuse of a building, it is not always possible, and we must look for other solutions to increase the productive lifetime of materials.

03 / How construction deals with waste

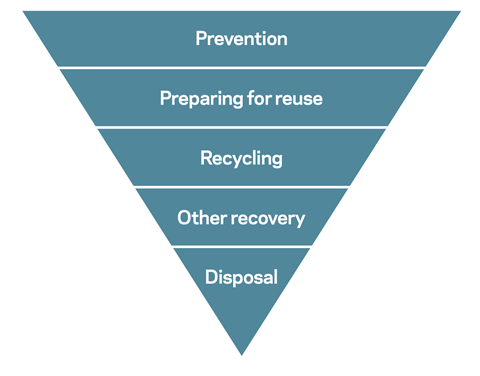

The waste hierarchy (depicted in the diagram below), as set out in article 4 of the EU Waste Framework Directive (2008/98/EC), ranks waste management options in order of environmental impact, starting with prevention and ending with disposal if all other options have been exhausted.

The waste hierarchy

The hierarchy gives a structure to consider efficient material use but also offers exceptions to the rule, in order to encourage lifecycle thinking. For example, could the reuse of building components increase the ongoing environmental impact?

Using the waste hierarchy as a template for what to do with an existing building would see an owner explore the following options:

- Prevention Building reuse, which would prevent the creation of waste and retain current materials in their present state

- Reuse Items of the demolished or stripped-out structure could be reused, such as steel members and stone facings

- Recycling Recycling of building waste into new materials

- Other recovery Using waste to generate energy

- Disposal Landfill disposal with no energy recovery.

04 / The business case for recycling

Planners have increasingly favoured building reuse – as opposed to complete demolition – in order to prolong the productive life of a current structure and its components. However, entire reuse is not suitable for all buildings at the end of their life, and complete or partial demolition may need to be considered.

For example, condition surveys could reveal that the building is not structurally sound or contains hazardous materials. The layout may be incompatible with modern needs or standards and require additional reinforcement. The glass and gaskets in the facade may be past the end of their serviceable life, and often it can be just as carbon- and cost-intensive to replace the entire facade as it would be just to replace the components.

The recycling of materials removed from a project through total or complete demolition may offer something of a solution to satisfy the need to make responsible use of construction materials. Not all materials are suitable for direct reuse but can still offer further utility elsewhere.

The decision to recycle or reuse materials needs to be made in the early stages of a project to ensure all parties are aware of the process that needs to take place and that key materials with the potential for salvage or recycling can be identified.

The evaluation process should include an assessment of the condition of the materials, any market value they may have, and the feasibility of transporting them to facilities where they can be processed effectively.

The resulting question is whether the process can be completed in a cost-neutral way whereby the value of the salvaged material may neutralise the labour costs involved in deconstruction.

Traditionally, it has not been uncommon for the salvage value of materials to be factored into demolition contracts, highlighting the financial incentives associated with sustainable practices.

The appetite for reused or recycled materials is increasing both in the built environment and in the market for consumer goods. This means that the utility and value of scrap materials or materials at the end of their life are increasing.

Below, we consider in more detail a site recycling approach, taking the example of a mid-rise office building in a city centre, built from a concrete core, with a steel frame and cast slabs on hollow rib, and a curtain walling system of aluminium and glass.

05 / How does the intention to recycle impact key packages and the implications for site activity?

How might a recycling approach impact a project that involves a mid-rise, city-centre office building, comprised of a concrete core, steel frame and cast slabs on hollow rib, and a curtain walling system made of aluminium and glass?

Preparatory work

Embedding a reuse or recycling strategy into a project needs to be done at an early stage. Before demolition begins, an audit of materials needs to take place to identify materials that can be reused or recycled. The desire to recover materials needs to be communicated to the project team to ensure appropriate space and time are available. A demolition contractor should be engaged early in the process to enable the extraction of materials, and space on site needs to be allocated for the temporary storage and processing of materials.

Structure

Concrete

The market for recycling structural materials is well established, which makes the process of reclaiming materials generally straightforward. Concrete and similar materials can be crushed down to rubble for reissue either on the project or at other construction sites. Of course, not all concrete can be reused; materials that contain asbestos or other forms of chemical contamination cannot be reused and will be managed differently.

Crushed concrete can be immediately reused as fill and hardcore, such as piling mats and sub-base materials, or used as primary aggregates. The process offers low carbon and cost-effective materials for new development on site.

Although most, if not all, concrete demolition waste can be reused, processing in a constrained inner-city site with limited space is challenging. In such cases, demolished concrete can be transported to a nearby recycling centre for processing and distribution.

Rebar is separated from the concrete as part of the crushing process. The rebar can be retrieved for the recycling process and used to create new reinforcing steel.

Steel

Steel salvaged from deconstructed buildings is exceptionally recyclable and boasts a significant end-of-life recovery rate; this means it also has a high scrap value. A study conducted by the Steel Construction Institute more than 10 years ago, in 2012, revealed that, on average, 91% of steel products were recycled, with heavy structural steel sections and light structural steel achieving even higher recycling rates of 93%.

Steel can be recycled repeatedly without compromising its performance; however, virgin steel is frequently favoured due to its established origin – as evidenced by the recent attempt to shut down Scunthorpe’s blast furnace. Demand for recycled steel has grown in recent years as developers seek less energy-intensive materials and the industry shifts to material sourced from electric arc furnaces, which consume vast amounts of steel scrap.

The demolition technique will be influenced by the value of the materials that can be reused. Hence a more careful deconstruction approach is often more practical to maximise the benefit of reusing structural steel materials. The longer the steel section, the better.

There are multiple methods to recycle steel that do not require extra energy for reshaping. Steel which has been cut to standard length is frequently reused after being tested to confirm its mechanical properties. This can sometimes happen within the same project, in which case storage space or facilities will need to be provided. If it is not practical to be reused, then it may be repurposed for uses such as temporary works or for agricultural structures like sheds or similar.

Facade

Curtain walling

Within a facade, there are several components that can be recycled, but glass and aluminium are key materials that play a vital role.

As an essential metal, aluminium can be traditionally recycled as scrap metal, transforming into new curtain wall framing or being repurposed into consumer products. Similar to steel, it can be reprocessed repeatedly without sacrificing its properties or quality.

There are a number of reasons why the glass within a facade may be removed, even if the overall structure is being retained. The glass may have exceeded its design life; and in older buildings, more modern products and systems will have been developed to provide enhanced building performance. Until recently, this glass would have been disposed of in a landfill site or used in glass fibre, but in today’s increasingly circular economy, glass can be remanufactured into new flat glass, albeit not on the same project due to the manufacturing process.

Specialist processors will first attend the site, assess the glass, and develop a strategy to remove it and arrange for it to be taken from the site to a place where it can be processed and recycled. Not all glass can be recycled; currently, back-painted spandrel glass cannot be recycled, and it is likely that some body-tinted glass (which previously was used for solar control) also cannot be recycled.

The glass needs to be uncontaminated and placed into dedicated collection bags to allow it to be separated from other waste.

Architectural and window glass is gathered into cullet collection bags, which are taken to a cullet processing plant where the glass will be crushed, inspected and treated before being mixed with other raw materials and remanufactured into new glass.

Cullet melts at a much lower temperature than raw materials and so requires substantially less energy, in addition to removing the need for additional raw materials. Industry statistics suggest that one tonne of crushed glass saves 1.2 tonnes of raw materials in the glass manufacturing process.

Material passports

To combat some of the barriers to material reuse, material passports are being developed as a digital way to store information on the characteristics of materials in a user-friendly way. The intention is to give them a transparent value, enabling them to be bought and sold, developing the idea that buildings should be seen as materials banks for future developments, to enable a greater use of circularity in the built environment.

The availability of higher-quality and more comprehensive information on materials within existing buildings can be greatly enhanced through use of developing tools such as material passports, which provide valuable insights into the composition of materials, supporting their potential for reuse.

Challenges and opportunities

A growing focus on efficient use of resources, cutting energy usage and emissions, has increased the demand for the reuse of construction components, and recycling when reuse is not feasible. Projects that are designed to promote a greater degree of reuse and recycling of materials or products could see benefits such as reduced landfill costs and an enhanced social value. However, successfully implementing these strategies is contingent upon engaging with team members at an early stage.

One of the concerns associated with the adoption of circular principles is the potential for increased costs or additional work, which could impact day-to-day work on site. The salvage process can introduce additional tasks on site, necessitating the careful segregation of different waste streams to ensure that materials are properly categorised for reuse or recycling, as well as transport and logistics for waste materials. Despite these challenges, it is important to recognise that the residual material resulting from these efforts holds intrinsic value, which could offset some of the associated costs.

Project teams must consider the storage space required for the segregation of materials, allowing subcontractors to effectively divide and manage the various waste streams, ensuring they remain free from contaminants. Establishing a clear waste management workflow is essential to streamline these processes and ensure that all team members are aligned in their efforts. On-site organisation emerges as an initial concern, particularly in the context of a constrained city-centre location where space is limited. However, proactive planning can mitigate these challenges, allowing for a smoother implementation of waste management strategies.

No comments yet