Belfast’s victoria square is a glitzy new shopping centre that keeps strong links with the street. david arminas talks to the team who delivered the services

Over the long years of the Troubles, Belfast’s shopping areas were continually disrupted by bombings, and the last big city centre retail development was CastleCourt in the late 1980s. In March, in a striking demonstration of how much has changed, the then first minister Ian Paisley and his deputy Martin McGuinness together opened the £400m Victoria Square.

“It was an iconic image,” says Belfast-born Paul Niblock, services director at BDP, the scheme’s architect and engineer. “Two former enemies standing side by side, saying how bright the future looks. I’d seen it all over the years and grew up with the Troubles. But now I’m part of this rebuilding effort, and I take great personal pride in that.”

The grand opening was the culmination of a 10-year struggle to revive an area previously occupied by two dowdy 1960s government office blocks, a downmarket retail area, an unloved square and a multistorey car park. “It was,” says Niblock, “pretty grotty.”

The city council wanted a retail-led regeneration project that looked and felt like a continuation of the streets rather than a separate mall. The task for the services team was to find a way of cramming in all the necessary facilities without intruding on valuable retail space or cluttering the roof with plant, Niblock explains.

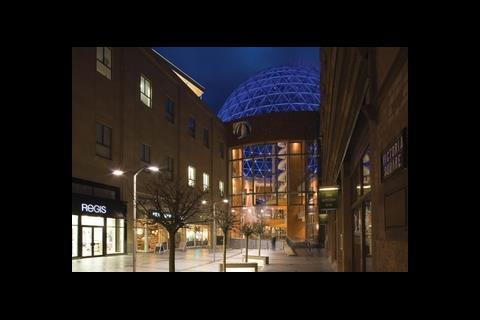

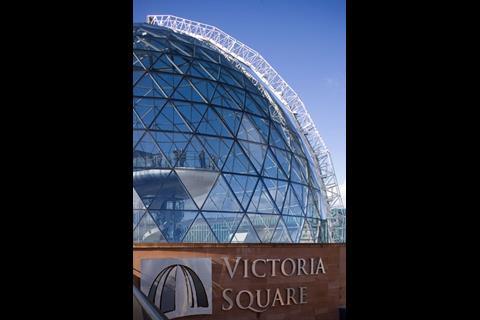

The grot has been replaced by a spacious, canopied shopping precinct with a cinema complex, more than 100 apartments and underground parking for 1000 cars. It is all capped by a showpiece glass dome giving panoramic views across the rooftops to the hills beyond. The 75,000m2 of retail space consists of more than 70 units anchored by an 18,000m2 House of Fraser store, Belfast’s biggest retail outlet.

On the former site of the rundown square stands the segmented glass dome, 35m in diameter, which rises 45m above street level. It sits on a 24m-high circular colonnade with a glass canopy roof. From the air, it appears as if an observatory has been dropped into the centre of Belfast. At night the dome has a blue glow thanks to hundreds of LED lights at the junctions of the internal framework.

The space beneath it provides the main pedestrian circulation. The retail street is split-level – shoppers descend about 4m to the lower ground, while the upper ground is a wide balcony. Although the entire street is covered by the glass canopy, it remains open at both ends.

“Because the street is an open development there are no active climate controls,” Niblock says. “But that doesn’t mean we left environmental conditions to chance because there is a lot of activity that flows from shops and restaurants on to the street. We did a lot of thermal modelling, our largest ever with a model for the entire scheme, and looked at temperature build-up in the dome.”

The initial concept was to use fritted glass, which has a ceramic coating, to reduce solar heat build-up under the dome and the surrounding area. “But looking through fritted glass is like looking through a mesh screen,” Niblock says. “We found that we could use a standard low-emissivity glass with some ventilation at the dome’s top. A fabric ‘solar sail’ was installed on the internal motorised cleaning gantry and it moves slowly with the sun to reduce direct sunlight. This system saved about 50% of the original cost of fritted glass.”

While the glass canopy provides weather protection, there were concerns it would lead to wind whistling down the street. RWDI Anemos, a wind engineering consultant, built a 1:300 model of the scheme for wind tunnel tests to quantify air movement according to Lawson comfort criteria. These define whether the wind environment will be “acceptable”, “tolerable” or “unacceptable” for specific activities.

“This allowed us to redesign aspects of the entrances, including installing a major glass screen dropping down from the roof to break up air flow,” Niblock says. “On the initial wind tunnel tests, before the dropped screen was introduced, the environment at the entrance was tolerable for standing but unacceptable for sitting. Introducing the screen changed this to acceptable for sitting.”

Having usable, clutter-free frontages for each retail tenant was essential to maximise rental value. Although the shopping centre remains effectively a street, the design avoids the need for it to house electricity transformers and water and telecommunications connections by routing them all – plus primary heating and cooling through a condenser loop system – into the back of tenants’ units.

Heating and cooling

The layering of mixed-use tenancies and the limited roof area meant there was little space for tenant plant. The unmanaged sprawl typically found on top of shopping centres had to be avoided because the roof is visible from the viewing platform in the dome. A central condenser loop system allowed the development to avoid large-scale rooftop plant for heating and cooling.

The loop reaches each tenant through dedicated risers and service corridors and feeds into the back of each unit, where the tenants connect their own heat-pump systems. The rooftop plant – which belongs to the landlord and consists of boilers and coolers connected to the two-pipe loop – has been screened from view. Parts of the roof are covered in sedum, enhancing the uncluttered appearance.

The closed loop system supplies constant-temperature water to every tenant to use for heating or cooling as required. “The condensor system gives an energy benefit,” says Niblock. “Between seasons, larger retail and residential units could be on cooling and rejecting heat while some smaller units will have a heating demand. Small units can recover their heat from the system without running their boiler plant. Another advantage was that during the hectic fit-out period, all the tenants had everything inside their units. There weren’t different crews running around installing individual condensors and pipework and hauling plant on and off the roof.”

Tenants pay for heating and cooling pro rata on a square metre basis, plus a service charge. “With the condensor loop, the energy consumption for heating and cooling is in the tenant’s plant. The tenant draws heat or coolth as required using a heat pump. All we are doing is getting rid of the heat in summer and injecting a little bit of heat in the winter from the boiler plant to keep it up to temperature.”

Space restrictions meant the designers had to rethink the electricity distribution. A conventional set-up would have been too restrictive and inflexible and would have taken up valuable space, says Richard Smyth, BDP’s electrical designer for Victoria Square.

Under a conventional design, the transformers of Northern Ireland Electricity (NIE) would have distributed HV to the landlord’s LV switchboards. Each tenant would have been responsible for its M&E and a customer of the electrical supplier, with its own cable snaking around service corridors to its premises. This would have increased the riser and corridor space required. Centralised utility company metering rooms would have been provided.

“NIE also has onerous requirements about where their transformers must go,” Smyth says. The maximum transformer rating is 1000kVA and all transformers are oil-filled so they must be accommodated and accessible in line with strict NIE rules. “It’s mainly a maintenance and access issue for them to get at their equipment. As with many city centre shopping areas, NIE wanted some of the transformers along the street in front of the shops,” Smyth explains. This would, however, have created problems for shops, restaurants and bars wanting to use their frontage areas.

Landlord is energy supplier

The solution was for the landlord to become the HV distributor and NIE to have a single 11kV supply to the HV switchboard. “The landlord set up an energy supply company to buy from NIE. The new company also owns the entire electrical infrastructure of the development. Because the landlord owns all main transformers and switchgear, we could put them wherever we wanted, such as in service yards or even on the roof. It all frees up that prime retail frontage,” Smyth says.

A resilient three-cable 11kV supply is provided; any two cables will carry the full load. Each cable feeds into a bus-coupled section of the HV switchboard. Power is distributed via three HV ring circuits feeding twin 2000kVA cast- resin transformers fitted with automatic fan-assisted ventilation. This allows for a transformer failure with no loss of supply, as the surviving transformer can carry the full load.

The landlord has saved more space by using a flexible LV distribution busbar running around the development in the service corridors. “Tenants just plug into the busbar and if a retail unit doubles in size, they simply unplug their original connection and plug in a larger one for the extra load.”

Under the traditional approach, NIE would have had several meter rooms and required 24/7 access. This space has been saved because all meters are within tenants’ premises. The computerised system allows remote metering by a third-party operator.

An additional benefit of this solution is that the landlord can buy HV energy cheaper than multiple LV supplies and sell energy to tenants at a discounted rate. The tenants have a cheaper and more reliable electricity supply while the landlord achieves maximum flexibility and the potential for a modest revenue stream.

Basement parking ventilation

Fire safety codes for the two-level underground parking area for 1000 vehicles were met with a ventilation design based on 100 impulse fans. A system of continuous ventilation ductwork would have required much more space, including for risers, Niblock says.

By using 400mm fans the service zone was reduced from more than 1m to 400mm. This gave significant cost savings as the excavation depth was reduced by 1.2m to about 9m. The system needs only two large risers at each end of the car park. Having only two made it easier to accommodate them in the retail areas above. It also allowed BDP to reduce from eight to four the number of stairwell accesses required for fire fighting.

In a fire, the main supply and extract fans will ramp up automatically to full speed and the impulse fans in the unaffected floor will switch off. All the fans are reversible so the direction is automatically selected according to the fire’s location. This allows maximum air flow to clear the smoke from the affected area, keeping other areas smoke-free for escape and to assist firefighters. Wire fire detector lines are located throughout the upper slabs. Heat from a fire will melt the wire, allowing the garage management system to pinpoint the blaze.

Victoria Square has captured the attention of many organisations, including the Royal Town Planning Institute, to which Niblock and his team have given presentations. “What’s good about a retail project is that it’s so open to everybody, a great equaliser of cultures,” he says. “Victoria Square is a project of European standards and it’s a good demonstration of the way the country is going – an embodiment of the optimism in Northern Ireland.”

Original print headline - Welcome to the megadome

Data sheet

Client: Multi Development/T+T Design

Architect, structural engineer and mechanical/electrical/environmental/acoustic engineer: BDP

Quantity surveyor: Cyril Sweett, Gardiner & Theobald

Project manager: Faithful & Gould

Fire engineering: Warrington Fire Research Mechanical contractor: Vaughan Engineering

Electrical contractor: JB Building Services

Main contractor: Farrans/Gilbert-Ash

Regulatory authority: Belfast City Council

Total cost: £400m investment cost, £160m construction cost

Building services total: £15m

Total net cost: £1097/m2

Total site area: 18,000m2

Gross floor area: 145,737m2

Plant rooms: 7,400m2

Retail: 54,771m2

Cinema: 3,734m2

Catering: 7,771m2

Residential: 10,764m2

Public circulation: 7,703m2

Parking provision: 30,103m2

Tender date: November 2004

Tender system: two-stage tender

Form of contract: design build

Contract period: four years

Completed: March 2008

External design conditions

Winter: -4°C

Summer (a/c): 27°C db, 20°C wb

Internal design conditions (streets and dome)

Winter: ambient

Summer (non a/c): not to exceed 28°C for more than 5% per annum

Structural details

Slab thickness: 325mm

Floor to ceiling: 4000mm

Live load: 4+1KN/m2

Dead load: 4.8KN/m2

Occupancy

Typical: 0.2 person/m2

Noise levels

Retail: NR 40

Residential: NR 30

Target energy use (gross floor area)

Gas: 32kWh/m2/y

Electricity: 104kWh/m2/y

CO2 target: 50kg/m2/y

Typical occupied hours: 9am–11pm

Diversity (hours/week): 100

BREEAM rating: pending

Calculated heating load: 1108kW

Installed heating load: 1200kW

Calculated cooling load: 3182kW

Installed cooling load: 3200kW

Electrical supply

12MVA at 11kV from energy grid

kVA standby power – 3x500kVA

Downloads

Source

Building Sustainable Design

1 Readers' comment