Navigate the complexities of fire safety regulations for internal partitions with this module, sponsored by Siniat. Gain essential knowledge on testing, extended application and third-party classification to confidently specify compliant and high-performing systems.

The tragic Grenfell Tower fire in 2017 served as a profound catalyst for change within the construction sector, fundamentally shifting the landscape of responsibility and highlighting the importance of safety at every stage of a building’s lifecycle.

The subsequent Hackitt report in 2018 delivered a critical assessment of the regulatory framework and industry practices, leading to significant amendments to Approved Document B (ADB) of the Building Regulations in 2019. ADB is a UK government document that provides guidance on meeting the Building Regulations’ fire safety requirements.

The 2019 updates directly addressed recommendations from the Hackitt report, notably introducing the role of principal designer. This key appointment placed greater responsibility on the principal designer to oversee the design phase and ensure that building safety is considered from the outset.

Further solidifying this shift was the introduction of the Building Safety Act 2022, with secondary legislation and implementation commencing in 2023. This further reinforced and expanded the regulatory framework for building safety, particularly for higher-risk buildings, through measures such as the new Gateway process – a series of mandatory checks at key stages of a building’s lifecycle designed to ensure safety is considered from planning through to occupation.

The legislation highlights the critical need for robust specification, placing a clear responsibility on all involved to ensure that specified systems are suitable for their intended application. A key element of this new era is the concept of the “golden thread” of information. This digital record-keeping process mandates the creation, maintenance and transfer of accurate and up-to-date safety and product information throughout a building’s lifecycle – from design and construction, through installation and maintenance, to occupation and eventual demolition. This requires robust test data and clear documentation to substantiate any claims made about a building’s safety and performance.

This evolving regulatory landscape necessitates a comprehensive understanding of product and system performance, including how test evidence is appropriately applied in real-world contexts. Rather than relying on interpreting test data, the use of formal classification reports – developed through standardised methodologies – is now strongly advised. These reports provide a structured, consistent means of verifying that products and systems meet the necessary performance standards. Moving beyond minimum compliance, the industry must adopt a proactive approach to risk management, embedding safety considerations into every stage of the building design process and increasing confidence that performance claims are backed by independently verified, third-party evidence.

Learning objectives

- Understanding of the evolving regulatory landscape for fire safety in the built environment.

- Knowledge of the critical steps involved in demonstrating the resistance to fire performance of internal partitioning systems.

- Awareness of the key considerations and responsibilities for manufacturers, designers and contractors in specifying and installing compliant internal partitioning systems.

Understanding the evolving landscape

The regulatory framework for construction product and system testing has evolved, affecting the assessment of internal partitioning systems and highlighting the ongoing drive toward a safer built environment. Before 2019, a transition from British Standards (BS) to European Standards (EN) was under way, but there was limited clarity around the use of formal EN classification and the consistent use of extended application standards. In the absence of clear guidance, manufacturers often relied on basic calculations and internal evaluations to demonstrate performance.

The 2019 updates to ADB reinforced the adoption of EN standards, known for their more rigorous testing protocols. While EN classification is not mandated, it is recommended within ADB and offers a more robust and transparent approach. It also supports extended application through standardised rules and independent review, helping to de-risk projects by ensuring competent evaluation of test data. The BS 476 series is being phased out, with EN standards set to become the only acceptable test method by September 2029.

This transition necessitates that industry professionals work to EN testing methodologies and classification practices to align with evolving expectations around compliance and specification.

Test

Fire resistance testing is a crucial stage in verifying the safety and performance of a system. The standard procedure involves selecting a representative base partition system that reflects typical construction details. This system is then subjected to a fire resistance test conducted by a UKAS-accredited third-party testing body in accordance with EN 1364-1. This standard specifies a method for determining the fire resistance of non-loadbearing partitions.

During the test, a specimen, typically measuring 3m x 3m, is exposed to heat within a furnace. The temperature inside the furnace follows a standardised time-temperature curve, reaching approximately 1,000ºC within a relatively short period. The partition system’s ability to withstand this intense heat is evaluated over time, depending on the desired fire resistance level, and results are rounded to the nearest standard fire resistance classification (for instance, 30, 60, 90, or 120 minutes).

Manufacturers can aim to exceed the target fire resistance duration by at least 10%, depending on the classification sought. For example, a system targeting EI120 would typically be tested for at least 132 minutes. This additional test duration helps demonstrate the system’s robustness and provides a basis for permissible extensions under EN standards.

While testing to a specific target duration is essential for achieving a particular fire rating, many manufacturers also opt to test their systems to failure. This involves continuing the test beyond the required timeframe until the partition system loses its integrity, insulation, or both. This comprehensive approach provides valuable insights into the overall fire performance characteristics of the system and its potential failure modes.

Fire resistance can be required for specific durations, ranging from 30 minutes to, in certain high-risk scenarios, up to four hours. It is crucial to recognise that drywall systems often constitute the most extensive fire-resisting elements within a building. As such, they are frequently penetrated by essential building services such as pipes, cables and ventilation ducts. The integrity of these penetrations is paramount. Therefore, it is important to ensure the compatibility of any services that pass through fire rated partitions, to maintain the overall system performance.

This is often achieved by direct fire testing or application of the tests using classification reports.

Extending test data to real-world applications

Regulations recognise that conducting a specific fire test for every conceivable partition configuration is not always practical or feasible. Therefore, the regulations outline a framework for assessing the classification of a product or system based on existing test data, provided this is done rigorously and transparently.

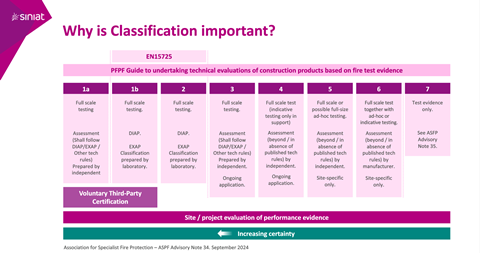

According to ADB, where a test is to be extended in lieu of a specific test, it must be conducted in accordance with the relevant standard for extended application pertaining to the original test. It must also detail the test evidence that forms the basis of the extended classification. For performance classifications where no specific extended application standard exists, assessment reports should be produced following the principles outlined in BS EN 15725: Extended application of test results for fire resistance and/or smoke control of building products and building elements.

These reports must also provide comprehensive details of the test evidence used to support the assessment. Further guidance on best practice in conducting such assessments can be found in the Passive Fire Protection Federation’s (PFPF) Guide to Undertaking Assessments in Lieu of Fire Tests.

A simpler method of extending fire test results involves taking the data obtained from a standardised 3m x 3m test rig and determining how it can be reliably applied to a wider range of real-life construction scenarios. This is achieved through the application of extended field of application (EXAP) standards.

EXAP standards provide a set of predefined rules and methodologies that allow manufacturers and assessors to extrapolate the results of a fire test to cover variations in the tested system. These variations might include:

- Increased dimensions: Within specified limits, the test results might be applicable to larger partitions.

- Variations in components: Certain changes are permissible under EXAP rules, such as increases in stud centres, stud thickness or size, and plasterboard thickness. However, changes to stud shape (for instance, from C stud to I stud) or plasterboard type (for instance, from fire board to fire moisture board) are not allowed and require separate testing for each variation.

It is important to briefly introduce another key term related to the application of test data:

- Direct field of application (DIAP): This refers to the limited variations from the design that was fire-tested.

Crucially, in the UK for single-frame internal partitions, the primary route for extending fire test data is through EXAP standards. This ensures a degree of standardisation and consistency in how test results are applied to diverse construction projects.

The critical stage of classification

Once a resistance to fire test has been conducted and the potential for extending the results through EXAP standards has been explored, the final step is classification. The mantra to remember is: test – extend – classify.

It is important to understand that an independent, third-party notified body must carry out all three of these stages. This ensures impartiality and provides confidence in the validity of the performance claims. Where manufacturers do not have classification reports available, questions should be raised regarding the process of extension from the test and the competency of the individuals involved, as this carries greater uncertainty than systems which have been independently classified.

The classification report will clearly state whether the resistance to fire performance achieved applies directly to the tested configuration or if it has been extended to cover variations included within the EXAP standards.

This information is crucial for specifiers to determine if a particular classification is applicable to the specific height and configuration of the partitions in their project. A classification report follows a standardised format, ensuring a clear and readable presentation of the essential information. Typically, it includes:

- Details of the tested build-up: A precise description of the materials, dimensions and construction of the partition system that was subjected to the fire test.

- Overall classification: The fire-resistance rating achieved according to the relevant EN classification standards.

- Field of application summary (DIAP or EXAP): A clear statement outlining the specific configurations and variations to which the classification is directly applicable (DIAP) or has been extended (EXAP), including any limitations on dimensions or construction details.

A full third-party classification offers several key benefits, including independent verification of resistance to fire performance claims, enhancing confidence in specified products and systems. This process also saves valuable time by negating the need to scrutinise raw test data – an exercise that is often open to individual interpretation and carries a significant degree of personal risk – allowing professionals to focus on other critical compliance aspects.

Furthermore, classification facilitates the seamless integration of resistance to fire performance data with other classified fire-resisting elements and allows for concise summaries to be readily incorporated into the golden thread of information. The move towards comprehensive classification is facilitating a clearer understanding of how these elements work together to maintain fire compartmentation.

Understanding single-frame partition EXAP rules

Applying EXAP standards for single-frame partition systems is governed by specific rules that dictate the permissible variations from the originally tested configuration. A thorough understanding of these limitations is crucial for accurate specification and to avoid inadvertently invalidating the resistance to fire performance claims.

Within the context of single-frame partition EXAP, certain fundamental aspects of the tested system are considered immutable. For instance, the exchange or replacement of the lining boards used in the original fire test is not permitted. Similarly, any change in the shape or fundamental profile of the steel studs from that which was tested is also not allowed.

This means that specifiers cannot, for example, substitute a standard plasterboard with a moisture-resistant or impact-resistant board, or change from a C-stud profile to a resilient bar system, and still rely on the same fire test evidence. Such alterations necessitate new resistance to fire testing to validate the performance of the modified system. Consequently, manufacturers are increasingly required to invest in more comprehensive testing programmes to cover the breadth of their system offerings. This may also mean that some less common or highly customised partition systems may no longer have readily available fire performance substantiation.

Regarding steel stud profiles, the common practice among manufacturers is to conduct resistance to fire tests using the smallest size of C-stud that they intend to be covered by the test. EXAP rules typically allow for an increase in the stud size from the minimum tested size, as a larger stud is considered to offer equivalent or better structural performance in a fire.

Understanding deflection head requirements

The deflection head detail, the junction between the top of the partition and the underside of the floor slab or roof structure above, is a critical area for maintaining the fire resistance of an internal wall.

The primary modes of failure in resistance to fire testing are typically related to insulation (the ability of the partition to limit temperature rise on the unexposed side) and integrity (the ability of the partition to prevent the passage of flames). The transfer of hot gases through gaps at the deflection head can lead to a failure of insulation, creating a risk of hot spots forming, potentially igniting materials on the non-fire side of the partition. EN testing has made this detail harder to pass the test and so changes have been made to designs.

The most common methods for achieving this restraint and preventing the passage of hot gases include the application of a metal angle in conjunction with suitable fire-stopping material at the head of the partition.

While a range of specific combinations and proprietary deflection head systems exist, this fundamental principle of providing a thermal and physical barrier remains consistent. This represents an important change for the drywall contracting industry, and it can have significant cost implications if not properly considered during the specification and installation phases.

It is crucial for contractors to be aware of these new requirements and to factor in the cost of appropriate deflection head treatments in their project budgets. Specifiers should check that the manufacturer has conducted resistance fire tests that specifically include and address the deflection head detail in accordance with the latest EN standards.

Cold state versus fire state

When considering the height limitations of internal partitions, it is crucial to differentiate between two distinct parameters: the cold state maximum height and the fire state maximum height. The cold state maximum height represents the maximum design height of a partition under normal, ambient temperature conditions. This height is typically calculated based on the mechanical and structural properties of the partition components, such as the steel stud gauge and spacing, and the type and thickness of the plasterboard linings.

In contrast, the fire state maximum height defines the maximum permissible height of a wall while still maintaining its designated EN fire resistance rating. This height is determined based on the observed behaviour of the partition during resistance to fire testing and the rules for extending the application of those test results.

The fire state maximum height is often lower than the theoretical cold state maximum height, and a partition that might be structurally sound to a certain height under normal conditions may exhibit different deflection or failure modes when exposed to the intense heat of a fire, thus limiting its effective fire-resistant height.

Methods for determining fire state heights

There are several recognised methods for determining the maximum fire state height of an internal partition system:

- DIAP: This involves conducting a standard fire test in a 3m-high furnace (as per EN 1364-1). The achievable fire state height under DIAP is typically up to 4m, allowing for an extension of one metre in height.

- EXAP: This method involves extending the results from a standard 3m furnace test based on the rules outlined in EXAP standards. Typically limited to single metal-framed partitions, achievable heights can be extended by up to an additional 3m – meaning a partition tested at 3m could potentially be approved for use at 6m – based on positive performance indicators during the fire test. These indicators include minimal mid-point deflection, a 10% overrun in fire resistance duration, and, for higher extensions, the addition of extra board mass to enhance thermal and structural performance.

- National annex (addendum to EXAP standard): Some countries, including the UK, have national annexes that provide additional methodologies for determining fire state heights based on calculations. These methods often require stud temperature data obtained during a standard fire test and are typically limited to single metal-framed partitions. By monitoring the stud temperature, they can perform analyses that may allow for increased partition heights, potentially reaching 10m or more. However, it is crucial to note that achieving these greater heights may come at the expense of the fire resistance rating duration.

- Overheight testing: This involves conducting fire tests in specialised furnaces that are significantly taller than the standard 3m height. The achievable fire state heights are largely dependent on the dimensions of the available testing facilities. However, this method has limitations due to the limited availability of such tall furnaces and the high costs associated with conducting these specialised tests.

A notable area where standardised test data is lacking is junctions and details – specifically, how fire-rated internal partitions interface with other building elements such as walls, floors and ceilings.

As it stands, there is no specific EN test standard available to comprehensively test the resistance to fire performance of these critical interfaces. For junction details, manufacturers will often provide recommended details based on extensive knowledge, expertise and bespoke testing. These should always be reviewed and approved by the principal designer and any relevant third parties prior to construction to ensure that all site requirements are met.

Given the complexities and nuances involved in determining fire state heights, it is highly recommended to rely on manufacturers that have invested significantly in testing and classifying their complete range of partition systems.

Always ask manufacturers for classification reports to verify the fire state height limitations for specific partition configurations. This ensures that the specified systems meet both the structural and fire safety requirements of the project.

Final thoughts

Independently verified classification by a recognised third-party body increases confidence that a partition system can perform as claimed, including achieving specified fire resistance ratings at designated maximum heights. This independent validation removes reliance solely on manufacturer declarations and significantly de-risks the process across the entire construction chain, providing greater certainty that the installed systems will perform as intended in the event of a fire.

Please fill out the form below to complete the module and receive your certificate.

No comments yet