Established in 2004, GB Environmental is at the forefront of UV technology for disinfecting water, air and surfaces.

Based in Chelmsford, Essex, the company employs 12 people and is expecting to turn over £1m this year. It works in the leisure, food and drink, municipal water and public building sectors. Ralph Coney explains how UV can spell curtains for unpleasant micro-organisms.

Describe your market?

We operate in a number of markets and we see the healthcare sector as having great potential, particularly given the current focus on infection control and the massive hospital build programme. It’s on the verge of getting big. Our products are also suitable for retrofit and temporary, emergency applications – they aren’t limited to new build.

We are competing with other UV technology companies, such as Hanovia, but infection control is a package of measures and our products are both competing with and used in combination with things such as bacterial and HEPA filters, as well as alcohol wipes and gels.

Why UV light?

UV light can be split into three groups of wavebands, UVA, UVB and UVC. The UVC waveband or germicidal wavebands are lethal to all micro-organisms and can be used to kill mould spores, airborne bacteria and viruses such as cryptosporidium, legionella, hepatitis and tuberculosis. Fortunately, the viruses we are trying to kill are the ones that are susceptible to UV light.

Who specifies your products?

Our products are mainly specified by M&E consultants or else by the infection control team at a hospital.

Which are the main products?

We have the Air Guard range of UV air disinfectors. These units fit into the ductwork of an air conditioning system to provide a germicidal barrier to passing micro-organisms. They can be retrofitted in places such as hospitals to prevent the transmission of contagious diseases.

On the water side, we have the Safe Guard range of UV water disinfection equipment. This can be used for things such as drinking water disinfection, protection of stored water from legionella and the protection of water distribution systems in buildings.

Are there any issues with maintenance?

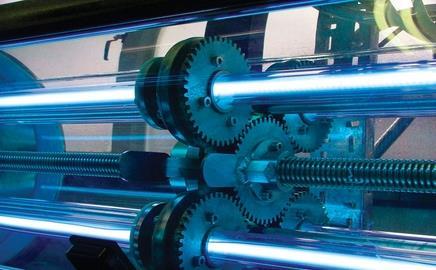

The systems have automatic cleaning and light management systems. If the UV light cannot get to the micro-organisms then it can’t kill them. Our cleaning system uses both a rotational and axial scraping mechanism that keeps the lamp sleeves clean.

What are the lead times on products?

The average lead time is about six weeks. All of our products are made to order. We would base the design on the size of the room and the airflow rate to the room and then build a system so that it delivers the correct dosage of light to meet these requirements.

Are you working on any product developments?

We have developed a freestanding portable unit that can be wheeled into a ward or a room and used to create an isolation room and protect a patient who might be vulnerable to infection. It simply plugs into a wall socket and is designed to recirculate the air in the room.

Something else we have drawn up plans for is a temporary isolation unit in which one of our UV disinfection units is hung above a bed and the bed is shrouded in anti-bacterial curtains and a canopy. It would be particularly suitable for emergency situations, such as an outbreak of bird flu. The next stage will be to build a demonstration system.

Specifier 07 December 2007

- 1

- 2

- 3

Currently

reading

Currently

reading

GB Environmental: Germ warfare

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

- 13

- 14

No comments yet