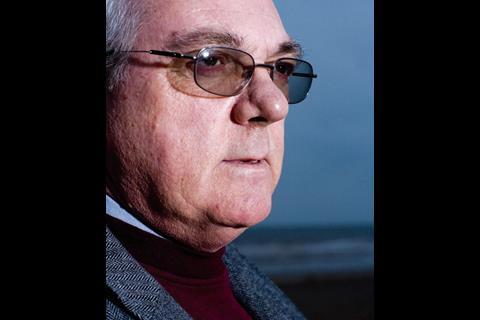

For the 25 years that he was a crane driver, Terry Duxbury endured the job’s unsafe conditions and culture of never speaking out. Here he tells Sarah Richardson about the terrible personal price he had to pay before he found his voice

Standing a short walk out onto the sands near his Skegness home, his dark suit jacket blown back by biting February winds, Terry Duxbury feels a quiet sense of triumph. “Walking on the sand is something I’ve rarely been able to do since my accident,” he says eventually. “But they say you’re not a real crane driver until you’ve gone over.”

It is almost nine years since Duxbury, 54, crippled his right leg packing up a mobile crane at the end of a two-week shift on a retail site in Greenford, west London. He fell down an unguarded hole, shattering his leg. Five years on, his leg was amputated.

According to Duxbury, his story illustrates conditions common to the crane industry, where drivers are pushed to work in unsafe conditions by hire companies who, in turn, are under pressure to do whatever they have to in order to hit deadlines. He has now added his voice to Building’s Safer Skyline campaign to prevent others from sharing his fate.

‘The loneliest journey I’ve ever made’

Delays in the steel supply to the project in Greenford meant that Duxbury had to move his rig around the site on his final day, filling in steelwork around the groundworks, which by this stage were already under way.

“There was a hole near where the crane needed to be. I asked the groundwork contractors to fill it in, but they didn’t.” Under pressure to get the steelwork finished, Duxbury worked around the pit. He finished his work and went to pull up the cranes’ stabilising jacks, his final task.

What followed has replayed itself in Duxbury’s mind ever since. “I stepped back to look under the crane, and I was going down. There was a reinforcing rod, it was going to pierce my chest – it would have killed me. I grabbed hold of it and must have passed out. When I woke up, I was lying in the hole. I was in agony. My left foot was all splayed out to the side”. He pauses again. “That was site safety. There was no barrier.”

Despite his injuries, Duxbury felt under financial pressure to return to work soon after the accident, worried his company would find a new driver if he stayed away. His firm agreed to let Duxbury return for a trial at his own risk, despite the fact that he was on crutches and doctors were still trying to treat his injury.

“My doctor said ‘On your head be it’.

God, I was in agony. I bet you’ve never seen a man on a site with a stick – it stuck in the mud. I was there on trial for one day, and it was too much for me. My leg swelled up beyond belief. I’d thought I was getting better, but I wasn’t. My leg was just rotting away.”

Five years and eight operations later, specialists at Liverpool hospital took the decision to amputate Duxbury’s leg below the knee. “They said I had an infection and my age was against me,” Duxbury says quietly. “I told them just to do it, but they made me go home first. When I went back … that was the loneliest train journey I’ve ever had, knowing they’d cut my leg off when it finished.”

A culture of silence

Duxbury says that the pressure to speed up work on site that contributed to his accident is apparent throughout the crane sector, with drivers being placed under pressure to cut corners on safety.

You empty your bottle [of urine] at the end, or just tip it out from the crane. You’re expected to stay there, in your own filth

“Most of the time, drivers risk losing their jobs if they speak up. Contractors will often ask hire companies to send a particular driver, one who has shown he’s prepared to play the game and take risks to save time.” For example, drivers of mobile cranes often complain that they do not have enough stable ground to support their jacks.

“The drivers should be allowed to say the ground isn’t wide enough. But then the contractor will ring the crane firm and say the driver is refusing to work, and the hirer rings you and says: ‘What’s going on, Terry?’ Nobody says anything then because it’s made clear you have the threat of losing your job.”

Duxbury says that despite relatively attractive basic pay for crane drivers of about £14 an hour, many contractors refuse to pay “maintenance time”, that is, the time needed to check the crane. This leads some drivers to skip maintenance procedures. And given that there will be pressures to work even if defects are discovered, carrying out extensive checks seems to many to confer little advantage.

Because of this culture of silence, Duxbury set up the website www.lifting-world.co.uk. Established in the year his leg was amputated, 2003, the site provides a forum where drivers of all cranes, from tower cranes to mobiles, can ask for safety advice.

“While I was at home, I had a lot of time for reflection,” says Duxbury. “Crane drivers can’t go anywhere to tell people what’s happening or to ask for help. From my own experience, the industry is just a series of closed doors.”

The forum has been a big success with drivers. It has more than 600 members, many of whom use the site to raise specific safety concerns. One tower crane driver wrote after the recent fatal collapse in Liverpool that he knew his crane – on an unrelated site – wasn’t safe, but that he was worried about refusing to climb. The United Crane Operators Association, of which Duxbury is a director, called the company in question and demanded it check the crane. An independent assessor condemned the machine.

The site has also enabled drivers to ask each other for advice on driving. Although drivers have a licence for particular models, the long duration of projects means they can sometimes find themselves being asked to operate a machine they have not used for a year. Duxbury says there is a bullying culture at hire companies which prevents drivers from admitting they need a refresher. “If you say you can’t remember, they just take the mickey. So you’re left to set up the crane and recollect what to do with all the levers, and the others on site are all staring at you.”

Forged documents, filthy conditions

Duxbury says there is a problem with forged competency documents among drivers, and the banksmen that they rely on to direct them. “You are supposed to carry certificates on site, but it might be that your insurance is out of date. If that’s the case, you tell the site manager you don’t have it there but you’ll have it faxed over from your company. Then you can use tippex or whatever.”

In Duxbury’s opinion, the only way to stamp out the problem is for original documents to be carried on cranes at all times, and for workers to have the right to inspect each other’s certificates.

Then there are the conditions under which many drivers are forced to work. Duxbury explains how tower crane drivers often skip breaks, because the time it takes to descend counts as downtime. Instead, they are expected to remain in the cab throughout the entire working day, urinating in a bottle and defecating in plastic bags. “You empty the bottle at the end, or just tip it out from the crane. You’re expected to stay there, in your own filth. On top of that, many are worried about deep vein thrombosis.”

Duxbury knows that conditions need not be this bad. During his time as a driver, he took his crane onto film sets to assist with stunts. One memorable experience was a job on the set of Kevin Costner’s Robin Hood Prince of Thieves. “The conditions are so much better than construction - regular breaks, top safety experts,” he says brightly, before staring at the sand once more.

“But nothing like that will ever happen in our industry, not until drivers can believe they won’t be sacked for saying no when cranes aren’t safe.”

Postscript

If you have any experience of the way crane drivers are treated, or want to support our Safer Skylines campaign email us at building@cmpi.biz

For more on the Safer Skyline campaign, go to www.building.co.uk/saferskyline

2 Readers' comments