Three more options for fast-track sustainable modular construction

Modcell

Like Arco2’s system used on the Bosvigo school, the ModCell (it stands for Modular Cellulose) concept is to take materials that are perceived as being “deep green” and combine them with modern methods of construction.

Designed for use in housing, schools and commercial buildings, the company says the super-insulated system results in buildings that meet the demanding PassivHaus specification. As a result, ModCell buildings can have zero heat requirements.

The roofing and cladding system comes in two varieties, ModCell Straw and ModCell Hemp. Both comprise a structural timber frame built out of sustainably sourced timber which is “infilled” with locally sourced straw bales or, alternatively, has Tradical Hemcrete sprayed into it. The panel is then plastered using a protective lime render.

The units can be used as load-bearing panels, up to three modules high or as free-standing, non load-bearing cladding panels, where a structural frame is employed.

Panel sizes vary, but the most common is 3,000mm high, 3,200mm wide and 490mm thick. These provide U-values of 0.13W/m2K and a fire resistance of two hours.

Panels can be lifted into position on site using a telescopic arm or crane – the weight of the largest panels is 1.7 tonnes.

Kingspan Tek

The Kingspan Tek Building System can be used to create load bearing and non-load bearing walls, roofs and floors of a complete building up to four storeys. Alternatively, roof and wall elements can be used individually with other systems or construction methods.

The system comprises structural insulated panels which perform in a similar way to an I beam. The OSB facing boards act like the flanges and the rigid eurethane insulation core acts in a similar way to the web.

The panels are made in northern Germany and have U-values in the range of 0.1W/m2K to 0.23W/m2K.

Outer walls are lined internally with plasterboard. Before cladding externally, a non-tenting breather membrane is fixed directly to the wall panels. A range of cladding options can be used, including a masonry spray render, an outer leaf of brickwork, or timber boarding.

Eurban

Eurban specialises in the design, manufacture, delivery and installation of solid timber building structures. These are large format panels rather than modules, which are compatible with most forms of external cladding, ranging from timber and brick to mineral render and composite panels.

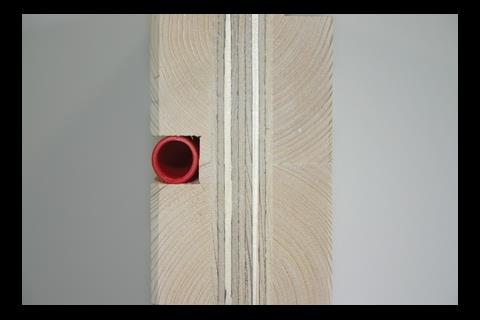

Fabricated in Germany by Finnforest Merk, LenoTec is a highly airtight panel, comprising strips of waste wood off-cuts and glue. The panels are self-supporting in two directions, so require no additional framework and can be used as load bearing walls and floors. They are made to order for specific projects and can be produced in dimensions up to 4.8 x 20m with thicknesses between 50mm and 300mm, and are airtight from thicknesses of 85mm upwards.

A typical construction for an external wall might include 12.5mm of gypsum plasterboard, an 85mm thick LenoTec panel, 140mm of Woodfibre insulation and a rear ventilated outer cladding.

Channels to accommodate services can be cut into the panels in the factory, allowing a rapid first fix.

Specifier 20 June 2008

Specifier 20 June 2008

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

Currently

reading

Currently

reading

The alternatives: Modular systems

- 11

- 12

- 13

No comments yet