Introducing our focus on HVAC, Graham Wright investigates air to water CO2 heat pumps, which offer building services engineers the next step in efficiency

Conventional heating products, such as condensing gas boilers, have reached the pinnacle of their efficiency. Reserves of fossil fuels, such as gas, are finite and produce carbon dioxide when they are burnt, adding to the effects of climate change. This has led to the uptake of alternative, lower carbon solutions such as heat pump systems.

As a result, air-conditioning companies have started to introduce air-to-water or ground-source-to-water heat pumps to provide low-temperature heated water for underfloor heating and hand washing. This type of technology has been available for some time in other areas of the world such as Japan and northern Europe, where it is seen as the best way of providing hot water for both light commercial and domestic applications.

These systems normally work with HFC refrigerants such as R410a but more recently CO2 refrigerant systems have been introduced, which allows higher water temperatures to be offered. The choice of system depends on the water temperature demand but as the thermodynamic properties of the refrigerants are totally different, the system’s efficiency can vary.

HFC air-to-water heat pumps have been available for some time. However, the latest products use inverter technology and improved heat exchanger design to improve efficiency.

While many products are intended to be installed by plumbers, there are still a significant number that will require specialist refrigerant handling because they have to be connected to a remote heat exchanger and consequently may also fall into the F gas regulations with a refrigerant charge of more than 3kg.

C02 units also use inverter technology. They do not need to be installed by specialists because the refrigerant is kept within the outdoor unit. This is connected to the thermal store by hot water piping. Moreover, C02 is a non-toxic natural refrigerant that is less harmful to the environment than other refrigerants. CO2 has an ozone destruction potential (ODP) of 0 and a global warming potential (GWP) of 1, offering an environmentally friendly heating solution.

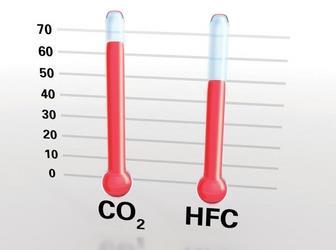

Using a CO2 refrigerant in a heat pump also allows a higher working temperature compared with HFC. CO2 heat pumps can achieve temperatures of 65ºC, compared with 40-50ºC with HFC units.

This means that there is no need for electric heaters to boost the water temperatures to remove the risk of legionella. Higher temperatures also mean higher storage capacity and more flexibility for different heating applications. The thermodynamic properties also allow C02 to operate down to -25ºC without any loss of capacity, while HFC units are often limited to -10 ºC with a significant drop-off in capacity below 7 ºC.

Defrost must be taken into consideration. Some HFC units use a hot gas defrost where the discharge refrigerant is directly injected into the outdoor coil to remove accumulated ice during long periods of continued running. Other systems reverse their operating cycle to use the heat stored in their associated water tank or heat exchanger for defrost, with electric heaters to make up the difference in lost capacity. C02 systems, however, use a direct injection system to prevent the loss of capacity and efficiency.

Heat pumps, such as Sanyo’s CO2 ECO, can be combined with renewable sources such as solar water heating systems to increase efficiency further and reduce carbon emissions.

Despite CO2 water heaters offering an innovative alternative to traditional heating systems, they are based on proven heat pump technology available worldwide.

The units have advantages over ground source heat pumps, which require higher initial investment for installation and may require planning permission. CO2 water heaters have high system efficiency and low running costs but also low installation costs, at the same scale as a room air conditioners.

Original print headline - The natural alternative

Downloads

Simple installation diagram for the CO2 ECO heating system

Other, Size 0 kb

Source

Building Sustainable Design

Postscript

Graham Wright is product manager at Sanyo Airconditioners

No comments yet