Phil Marris introduces this month’s focus on heating systems by describing a new radiator system that widens the options for heat pumps

Recent technological advances in the heating industry mean it is now possible to have compact, highly responsive radiators working with heat pump systems.

This ground-breaking technology gives specifiers and contractors that are considering using heat pumps a new option in their choice of heat delivery mechanism. Heat pumps need no longer be confined to use with underfloor heating or oversized radiators.

Now they can be combined with highly responsive compact radiators that allow precise climatic control and perform efficiently at flow temperatures as low as 40°C.

In addition to these benefits the low-mass radiators are claimed to open the door to heat pumps in refurbishment projects, where underfloor heating may not be practical.

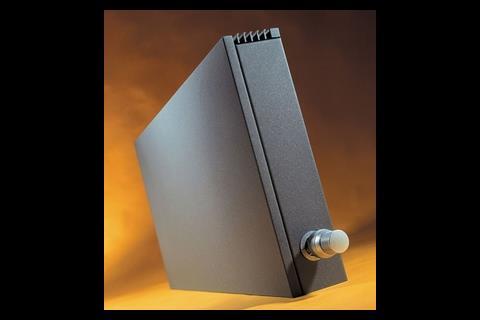

A Low-H20 radiator is only one- tenth the weight of a traditional radiator and contains around one-tenth of the water volume too. The low thermal mass and reduced water content mean the radiators store far less heat and therefore react three times faster to fluctuations in temperature. This reduces the amount of energy wasted during the heating up and cooling down periods.

With the addition of a dynamic boost efficiency unit (DBE) to the Low-H20 heat exchanger, it is possible to improve output levels by as much as 250%, allowing for much smaller radiators – about one-third the size of an equivalent output steel panel radiator.

The DBE unit contains a microprocessor-controlled thermal activator. It is concealed in the radiator and positioned on top of the Low-H20 heat exchanger. The unit is also equipped with intelligent sensors that constantly measure the temperature in the room and the water temperature in the heat exchanger.

If the room temperature falls below the pre-programmed lower limit, the microprocessor will silently increase heat emission to reach the desired temperature again. Once this has been achieved, heat output will automatically be reduced.

Sustainability is the issue of the day and we are all becoming increasingly aware of our responsibilities in preserving our depleted natural resources. Two great environmentally friendly technologies such as heat pumps and DBE working with each other is a positive step in the right direction and an exciting development for the industry.

Combined wood pellet/solar system

Nu-way says running costs for its combined EcoFlex wood pellet boiler and solar panel are equal to or less than oil fuel. The system comprises a 20kW nominal output wood pellet boiler, a 400-litre fuel hopper and conveyor, a 300- or 400-litre stainless steel thermal store and mains hot water unit, a three-port motorised mixing valve and head and solar panel.

More information 170

Cost-saving hot water system

Zenex Technologies has applied its CoolFlue technology to a domestic hot water system that it says can save households 50% on costs and double the flow rate.

The Zenex Super Efficient System, which operates with a 32kW combi boiler, provides flue gas heat recovery using the Zenex GasSaver, and a high flow rate capability over selected periods, via the Zenex primary circuit heat storage cylinder. It is simple to install and will deliver up to 20 litres of hot water a minute for 10 minutes – enough to fill two baths. Regeneration time is six minutes.

More information 171

New bypass valve

Altecnic’s new Eres bypass valve for central heating systems is designed to prevent the pump from working against a closed circuit when all the control or thermostatic radiator valves are closed. It ensures a flow recirculation proportional to the number of valves closed, while limiting the maximum differential pressure generated by the pump. The valve can be fitted in any position.

More information 172

Flate plate collector

Vaillant’s new auroTHERM plus VFK 990 flat plate collector can be mounted on or integrated into a pitched roof. The collector, with special anti-reflex coated, toughened 4mm glass, consists of an ultrasonically welded copper grid with a high selective absorber coating and 60mm rear and side insulation, encased in a polished aluminium frame. Panels can be connected in series in horizontal or vertical orientation.

More information 173

Failsafe condensing boilers

Clyde Energy Solutions has added M770 and M900 models to its range of Modulex high-efficiency condensing boilers. Both cast aluminium alloy boilers have multiple burners to ensure failsafe operation and eliminate the need for standby boilers. This also assists compliance with Part L. Flue gas condensing, premix burner technology and modulation ensure maximum energy efficiency.

More information 174

Source

Building Sustainable Design

Postscript

Phil Marris is managing director of Jaga Heating Products

Original print headline: "Pump action" (Building Services Journal, February 2008)

No comments yet