Built nearly a decade apart, the Queens Building at De Montfort and the Centre for Mathematical Studies at Cambridge were both cutting-edge examples of university architecture in their day. They were also both participants in the PROBE project to research buildings’ energy efficiency. Roderic Bunn revisits to compare their ratings then and now.

Queens Building, De Montfort University

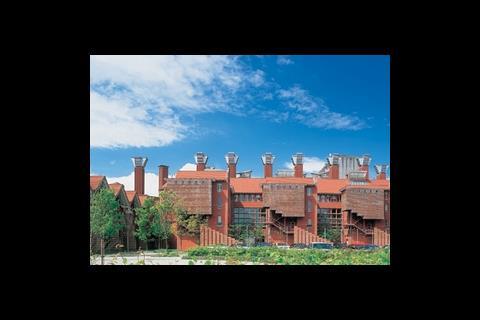

Completed in late 1993, the Queens Building at De Montfort University, Leicester, quickly gained a reputation as a structure that pushed the boundaries of traditional services design. Its startling architecture – in particular the distinctive ventilation chimneys – was intended to reflect the innovative ethos of what was then a new university. The designers were also pioneering in their use of natural ventilation, daylighting and passive solar design. Queens was seen as the first in a new generation of low-energy, naturally ventilated buildings.

PROBE findings

A detailed picture of the building’s performance was revealed in 1996, when a rigorous post-occupancy evaluation was carried out as part of the PROBE project. The assessment revealed a number of key shortcomings.

Significantly, the research team found that the original commissioning period had been compressed into a six-week window before the start of term in October 1993. Unresolved defects meant that for the first two years the building operated with problems in critical mechanical and control systems. For example, motors and actuators serving the rooflights were not properly commissioned, with the result that many motors burned out trying to drive the actuators past their stops.

The building's thermal massing and complex natural ventilation seemed to be effective at maintaining a comfortable environment, although the survey of its occupants, conducted by Building Use Studies (BUS), showed dissatisfaction with high summertime temperatures, particularly on the third floor, and stuffiness in both winter and summer months.

PROBE researchers also found that even the design’s copious provision of daylight was not enough to displace use of electric lighting. This appeared to be the result of a failing of the control systems – and of the building's users. For the occupants themselves, the greatest concern was noise, largely stemming from the open-plan areas, which academic researchers, used to private labs and offices, found difficult to adjust to.

However, the investigation did show that the Queens Building’s claims to low use of energy were largely borne out in practice. Based on a treated floor area of 8,400 m2, gas and electricity consumption was 143 kWh/m2/y and 52 kWh/m2/y respectively. This compared favourably with the Energy Efficiency Office’s low target consumption for university buildings of 185 kWh/m2/y and 75 kWh/m2/y respectively.

The revisit

A revisit during early August 2006 revealed that some parts of the building have changed dramatically since the PROBE assessment, while others are much as they were when it took place.

The desk-based staff of the Institute of Energy and Sustainable Design (IESD) now occupy the former m&e laboratory, while the double-height heavy engineering laboratory has been separated by a mezzanine floor, with laboratories on the first floor. This reflects the university’s shift away from engineering to maths, chemistry and media studies. The smaller engineering facility on the ground floor now shares space with media units and TV studios.

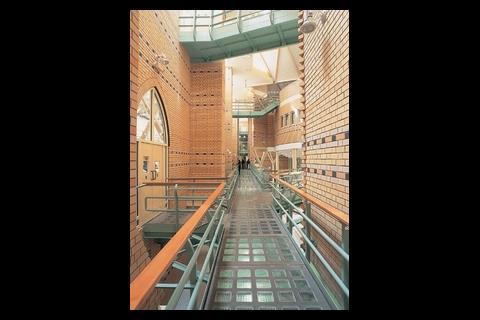

IESD staff enjoy a large space that has single-sided natural ventilation with stack-assisted exhaust through motorised rooflights. The natural daylight from the west-facing elevation comes with the penalty of glare from low-angle sun. This didn't bother the previous occupants, but full-height blinds with pull-cords have

now been installed, and the IESD staff use them regularly.

The IESD has replaced the motors for the rooflights. The original motors burned out shortly after they were installed because the designers did not know how powerful they had to be, or how far they should drive open the windows. A decade might seem a long time for failed motors not to be replaced, but the engineering staff weren’t bothered by the leaky rooflights – they tended to move around more, and they were warmed by the large, heat-generating machinery. Today, IESD staff open and close the rooflight vents via wall-mounted switches.

The windows serving the IESD offices can mostly be manually opened. The pivot mechanism has two settings: open and closed, with no intermediate position. This might have been acceptable for a machine shop, but sedentary workers require finer control. IESD staff have improvised ways of wedging the windows – finding that different-sized rolls of Sellotape give different rates of ventilation. Some windows have now been fitted with motorised actuators. Once a new BEMS is commissioned, the IESD will be able to introduce a night-cooling regime.

The new upper floors

Installation of a mezzanine, internal solid walls and partitions on the first floor to create laboratories required a complete rethink of the ventilation strategy. Originally, fresh air entered the ground-floor machine hall via ventilated buttresses. Today, this air crosses the machine hall and enters a central corridor through a series of transfer grilles. Extract is then out through the original ridge ventilators.

The only way to ventilate the first-floor laboratories was by knocking vents into the ventilated buttresses at that level, and relying on enough natural buoyancy to drive air through the ridge ventilators. But in practice, these laboratories do not seem to get enough air, and conditions are noticeably uncomfortable. The wing has undergone further changes of use since the ventilation system was reconfigured, and in places it seems unable to cope.

Occupants of the labs also suffer glare from the apex windows, way beyond their reach, and currently they have no blinds or other mechanism by which to control it.

The third floor of the Queens Building was originally designed as an open-plan drawing studio, with lots of daylight from glazed ventilators in the roof gables and large, triangular windows on the east-facing elevation. But drawing boards went out of fashion not long after the building was occupied. Today, it is home to banks of computers for student use.

As in the machine shop, the motors serving the ridge ventilators soon burned out. Previous occupants of the space found ways to wedge the ventilators open, but at the time of writing the vents were found to be closed and the power turned off. There seems little effective ventilation in this space. With a lack of thermal mass in the roof, heat from the computers and hot air rising from low levels, the former drawing studio is a hot space in summer.

The auditoriums

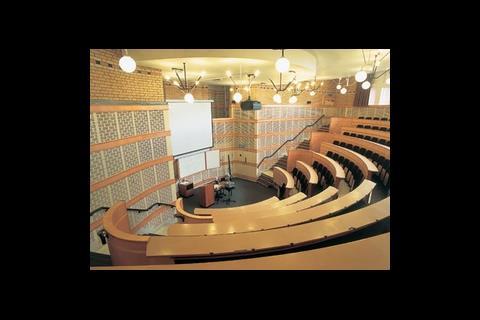

The hemispherical auditoriums sit side by side along the north-west elevation. Both rely on buoyancy-driven ventilation, with incoming air tempered by traversing a concrete plenum beneath the seating and extracted through tall, insulated chimneys. The strategy has worked well for the auditorium that is orientated with its raked seating backing onto the road. But it has arguably failed for the other auditorium, which was rotated through 180º as a space-saving initiative (see below).

Some incoming air for this latter auditorium travels a convoluted route to reach the seating plenum, but the greater proportion of it takes the line of least resistance, entering the space directly past heating coils set into the perimeter wall. The incoming air is simply not in contact with the heating coils long enough to raise its temperature, and a lack of turbulent flow creates serious stratification problems. This can lead to an 8°C difference between the upper and lower seating areas. Malcolm Cook, reader in building ventilation at the IESD, thinks blanking off a section of the supply grille may encourage better mixing.

Energy consumption

In 1996, gas and electricity consumption was 143 kWh/m2/y and 52 kWh/m2/y respectively. In 2004, the energy figures were 176 kWh/m2/y for gas and 87 kWh/m2/y for electricity – close to the original EEO benchmark but still heading the wrong way.

While the increase in electrical use may arise from a combination of more computers and a change of use of the engineering wing, the relatively inefficient electric feature lighting in the main concourse has defaulted to “on”, despite very good daylighting. Lighting control in many open-plan areas and laboratories also seems non-existent or nonsensical. (In one lab, the fluorescent lights were on in the daylit perimeter, but off in the central area.) A notable exception is the IESD offices, where a daylight-linked dimming system has been installed.

The increase in gas consumption is largely attributable to difficulties with the heating. Three major problems were resolved in 2005: rezoning of the heating system so that demand in one area doesn’t bring on the heating in others; extra pipework to create new heating zones; and the replacement of two- and three-port valves which had seized. More recent energy figures may show an improvement.

What the occupants think

During our revisit, BUS conducted another occupant survey. Forty-five questionnaires were completed (compared with 75 in 1996). In general terms, satisfaction with temperatures in both summer and winter is the same, although occupants perceive the air in winter to be better (see right). Productivity has improved by about 4%, but the building still suffers a minus score as it did in 1996. Lighting and noise scores are better.

Levels of satisfaction are very dependent on location. For example, the relatively high satisfaction rate for the refurbished IESD offices is not matched by users in the new laboratories.

Conclusion

The area that now houses IESD can be deemed a successful part of the building. Incorporation of TV studios and media facilities into the ground floor has also worked well. However, the laboratories created on the first floor suffer from insufficient buoyancy to drive the natural ventilation, and lack of storage space is another problem. The former drawing office on the third floor of the main building suffers from overheating. Also, direct solar gain on the lightweight roof, along with high heat gains from computers, make this area very hot in summer. Electric lighting tends to remain on in this space, despite the fact that it receives lots of daylight.

So, does the building deserve its iconic status? Given that so much of its ventilation and daylighting is determined by its bricks and mortar, it’s hard to avoid the conclusion that the Queens Building is rather stuck in a time warp. It’s difficult to improve or alter it, apart from changes to heating circuits and replacement of valves and motors. And elements such as these should not be “fit-and-forget” – they are critical to the building’s operation, energy efficiency and occupant comfort. The saving grace is that the users seem willing to forgive the transgressions on comfort and lack of user control in the belief that they are working in a building worthy of being loved for its very idiosyncrasies.

Centre for Mathematical Sciences, Cambridge University

Resolving issues of the cosmos and advanced mathematics requires a clear head and a quiet environment, so it’s fitting that the Centre for Mathematical Sciences at Cambridge University – home to Stephen Hawking – moved the art of mixed mode ventilation and comfort cooling on to a new level. When the first phase of the

multi-building development was completed in 2000-2001, it offered an interesting example of advanced natural ventilation, with automatic controls and manual override for the opening windows and vents, and clever use of internal blinds – as much to reduce light pollution as to prevent glare.

PROBE results

When the PROBE study was undertaken in 2002, the second phase of the project had not been completed. Looking only at the first part of the project, the researchers found that the design strategy of exposed thermal mass, solar shading, buoyancy-driven single-sided natural ventilation and night cooling was essentially sound. But departmental billing had not yet been implemented, so it was not possible to undertake a detailed energy analysis.

Although an airtightness test of Pavilion D (see plan overleaf) returned a value of 19.03 m3/hm2, the buildings were designed before airtightness values were stipulated in the Building Regulations. The planar glazing on the first floor above the entrance from the concourse was particularly leaky. There was also air leakage through the high-level ventilation outlets, and at the sills and reveals of the fixed corner windows. Very significant air leakage occurred through perforated steel panels enclosing services risers. Airtightness was apparently improved for the phase 2 pavilions, although no pressure tests were carried out.

The combination of automatic and manual control of ventilation gave mixed results. The overall approach proved sound, but occupants reported irritating delays in windows driving to new positions. In the phase 1 pavilions, the controls for blinds and windows proved unintuitive to use, and confusing for new occupants.

The recent visit

The CMS was a prime target for a revisit because all pavilions are now complete and the new occupant survey is able to cover the phase 2 buildings as well. The assessment of the phase 2 pavilions began in 2005, culminating in a new energy and occupant survey in summer 2006. While Chris Parkin of Roger Preston and Partners – the scheme’s building services consultants – concentrated his study on the phase 2 pavilions (F, G and H), feedback was also obtained on the phase 1 and phase 1a buildings (see overleaf). The facilities team reported that some of the pumps in phase 1 had been retrofitted with inverters to achieve the correct operating point. In some cases, smaller pumps were installed.

The air-handling units are equipped with run-around coils that pre-heat or pre-cool the incoming air. A cooling coil provides dehumidification and cooling, while a re-heat coil deals with any supplementary heating needs. Re-heat coils in multi-zone supply ductwork systems allow for local control of heating and cooling.

Unfortunately, it is not clear how the system should be controlled. On the day of the revisit, it was evident that incoming fresh air at 17°C was being heated by a run-around coil to 19.7°C, then cooled to 15.9°C and finally reheated by a duct reheat coil to 21.4°C. The fault probably lies in the setup of the cooling coil and its interaction with the run-around coil, something that requires closer investigation.

The quality of the operating and maintenance manuals is regarded by the facilities team as inadequate and incomplete. As a consequence, the facilities team does not have a strong grasp of how the systems are supposed to work. Furthermore, the site’s two BEMS systems are largely used for fault-finding rather than energy management.

In the cellular offices, the manual override controls for blinds and windows demonstrate the importance of good ergonomics. In phase 1, the user controls are still not intuitive. The buttons were not labelled by the controls supplier or installer, and the occupants were forced to add their own labelling with indelible markers. In phase 2, far more attention was paid to usability. The controls are clear in purpose, well labelled, and have red lights that give immediate feedback.

However, conflict between the demands of the central BEMS and the needs of the occupants occurs in all pavilions. Weather override is under the control of the BEMS, which closes windows when it rains (and opens and closes them for cooling). Not only is there a delay in window actuation, during which time rain can get in, but also the BEMS can’t remember users’ preferences. For example, if an occupant has opted to have the windows closed on a hot day, and it rains, when it has finished raining the BEMS will open the windows to cool the room. Occupants have to reset their window and blind positions – one said they have to do this twice before the system settles down.

For a site with hundreds of window-opening motors and actuators, the system has proved robust. However, in Pavilion A, almost every window motor has been replaced since 2001. The new motors have software that only drives them for a certain period to prevent them trying to push the actuators beyond the point of maximum window opening. For the earlier motors, a pressure device would sense that the window was fully open. When those sensors failed, the motors would continue to drive the actuators, forcing gears to slip over the chains.

Lighting throughout the site is under the control of a Philips ECS system. Absence detection was used in phase 1 to cover for occupants failing to turn off lights when they left. As most occupants of the (largely cellular) offices do turn off their lights, it was decided not to extend the system to the phase 2 pavilions. In any case, it proved to be a mild irritation to occupants seated for longer than 20 minutes, because the system turns off the lights.

Lighting has significant out-of-hours use, because of long working hours. When a person enters a pavilion at night, all access routes stay lit for security reasons. In phase 2 pavilions (which have no passive infrared detection) the lighting can stay on all night.

Energy performance

Pavilions F, G (which house boilers and pump sets) and H were subjected to an energy assessment to stage 2 of the CIBSE TM22 Energy Analysis Reporting Method.

Computing power is a significant load. Pavilion F is home to a COSMOS supercomputer that runs 24 hours a day. The maximum load of the computer and its accessories is about 36 kW, but there is no sub-metering to verify its consumption. Occupants’ computers are left running overnight in all pavilions as a matter of IT policy, primarily to perform campus-wide mathematical calculations but also to enable software upgrades and maintenance.

Treated floor areas were estimated with guidance from Energy Consumption Guide 19 and using this the averaged electricity consumption for each of the three pavilions is estimated at 106 kWh/m2/y (20z6 kgCO2/m2/y). There are no established energy benchmarks for the CMS type of building, so Parkin created a set of bespoke benchmarks based on the proportions of the pavilions that were either naturally ventilated or air-conditioned (the latter estimated at 20%). Adjustments were also made for longer operating hours, but at a reduced 2,300 degree days per year. As a consequence, electricity use comes in between the bespoke good practice benchmark of 74 kWh/m2/y, and a typical benchmark of 126 kWh/m2/y.

It was not possible to disaggregate the gas consumption of the three pavilions from that of an adjacent Ambient Flow Facility building (AFF), because there is no sub-metering on the gas supplies or heat meters. The gas consumption figure is therefore based on the sum of the treated floor areas of the pavilions and the AFF (5,007 m2).

Correcting for degree days, the (estimated average) gas consumption for each pavilion is 155 kWh/m2/y – considerably higher than the bespoke good practice benchmark of 86 kWh/m2/y but below the typical benchmark of 163 kWh/m2/y.

What the occupants think

In 2001 an occupant satisfaction survey in Pavilion B, plus smaller studies of Pavilions C and D, found the buildings were seen as comfortable: responses were in the top decile for overall comfort and air quality in winter, lighting overall, comfort overall and needs. Relatively low scores were given for temperature in summer, space at desks and health perception.

In July 2006, an identical survey was carried out in the three phase 2 pavilions. As in 2002, the pavilions returned very good scores for all criteria except air temperature and air quality in summer (see right). The aggregated scores may be adversely affected by the large proportion of Pavilion B that has a high south-facing component, and the problems with user controls and window opening. July was also the warmest month since records began, with a maximum temperature of 35.6°C measured in Cambridge University Botanical Gardens on 19 July, compared with the dry bulb design condition of 28°C.

The lanterns for phase 1 were built in situ by a contractor inexperienced in bespoke design. Phase 2 pavilions benefited from more airtight detailing, particularly around risers and the lanterns. The latter were built on the ground and then craned into position. User controls for window and blinds were vastly improved for the phase 2 pavilions. Less successful are some of the run-around coils, which are running inefficiently, wasting refrigeration and pump energy. The fault lies in a lack of control over when and how to operate the heat recovery, and a lack of facilities management time.

Conclusion

Overall, the CMS is an extremely agreeable place to work and the site plan fosters a strong sense of community. The buildings have aged well, a consequence of a good choice of materials and high levels of services maintenance.

The CMS highlights the virtues of good user controls and the importance of proper operating and maintenance manuals so the buildings can be run in line with the design intention. The lack of heating and chilled water sub-metering, absence of energy monitoring software and inability of the facilities staff to spend any time on energy-saving activities militates against improvements in energy efficiency.

Despite these shortcomings, the estimated energy consumption has bettered what might be considered typical for buildings of this kind. It would be interesting to see how the site would improve given sufficient time, effort and metering technology. n

The original design, Queens Building

Architect Short Ford Associates worked on the building design alongside environmental engineer Max Fordham LLP. A team of advisers backed them up, including Cambridge Architectural Research (on the stack-effect chimneys) and Bristol University (on the physics of the airflow).

The result of their collaboration was a highly insulated, thermally massive envelope, with mostly shallow-plan floor plates and generous ceiling heights. The 10,000 m2 building is L-shaped, with the south-facing wing comprising a full-height engineering laboratory, and a four-storey east wing containing a complex arrangement of laboratories, classrooms and offices.

The structure is almost exclusively naturally ventilated: there is cross-ventilation for the narrow wings, and chimney stack-assisted for the main building. The top floors are ventilated by motorised ridge windows.

The original design, Centre for Mathematical Sciences, Cambridge University

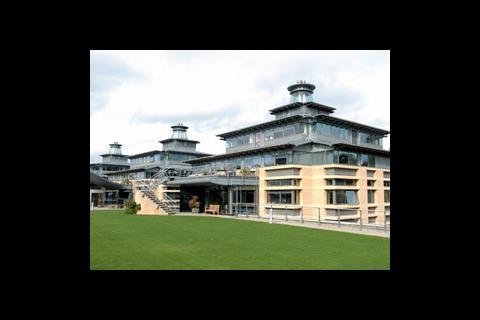

The CMS comprises six pavilions, one double-size pavilion, a gatehouse and a library on a greenfield site west of Cambridge city centre.

The 20,000 m2 development was designed by Edward Cullinan Architects, with Roger Preston & Partners providing services consultancy, and the first phase was completed in 2000-2001.

Six of the pavilions are very similar in design. Each has a lift shaft in the centre, surrounded by a spiral stair encased in a concrete and glass block tower, topped with a glazed lantern.

Circular corridors give access to cellular offices around the perimeter. Lecture theatres, common rooms and meeting rooms are mainly located in the basements.

Pavilion A houses the large, barrel-vaulted and grass-roofed cafeteria, along with some administration offices and the main reception. Pavilion B is double-sized.

All the buildings are predominantly naturally ventilated, although mechanical ventilation with comfort cooling is provided for lecture theatres, some internal rooms, and areas with high heat gains.

The phased development of the site means it has two separate building management systems: a Siemens system for phase 1 and a Honeywell system for phase 2.

Downloads

Occupant satisfaction survey

Other, Size 0 kbOccupant satisfaction survey of the CMS building

Other, Size 0 kb

Source

Building Sustainable Design

No comments yet