This summer the spectacular new Wembley Stadium opened its doors for the first time. The building’s services are one reason why the new venue is better than the original. Here we outline five key technologies that make it one of the most advanced stadiums in the world.

Lighting

Light levels for high definition television were the driver for the pitch lighting design. TV cameras shoot the action from the sides of the pitch, so in addition to getting the correct lighting levels on the playing surface, the challenge for the design team was to ensure a uniform vertical lighting level of 2,000 lux across the field of play.

Wembley uses 400 floodlights, manufactured by Thorn, to illuminate the pitch. These are suspended beneath the roof trusses parallel to the touchlines to keep light spill to a minimum. One unique feature of the stadium’s lighting design that goalkeepers will appreciate is that the floodlights are not positioned over the corner flags, giving the goalie a chance when facing a corner kick.

Complex rendering software was used to position the lamps. Aiming angles for the 2,000 W floodlights are interlaced to eliminate shadows for the TV broadcasts and to create a uniform light level.

The floodlights use unjacketed 2 kW metal halide lamps with a cylindrical quartz arc tube connected at each end. Because the lamps are slim and double-ended they can be accurately positioned within the luminaire.

Aiming of the lamps took place during the day using a grid laid on the playing surface, with the aiming position of each lamp indicated by a flag. The grid conformed to a prepared drawing. A rifle-type aiming attachment was used to aim the floodlight at the flag. Then an illuminance test was carried out at night to ensure compliance with the standards.

The scheme provides six preset lighting levels to meet FIFA guidelines and broadcast standards. This has been achieved using programmable switching. Lighting levels can be adjusted for non-broadcast, practice, concert and emergency modes.

All pitch lights are supported by a UPS to ensure continuity of events.

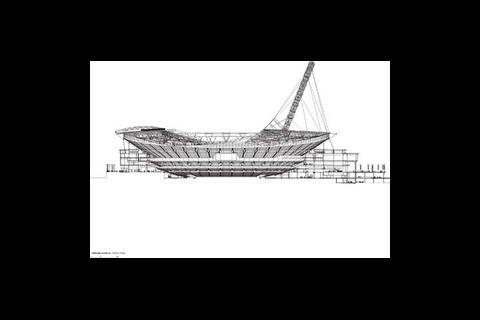

In addition to the pitch, a key feature of the Foster & Partners design for the new stadium is its partly retractable roof. When fully open, it allows sunlight to reach the whole pitch – essential to maintain the turf. In poor weather the roof can be closed in one hour to cover all 90,000 seats.

The roof is supported structurally by the stadium’s 315 m span, 135 m-high landmark arch. This is dramatically illuminated at night to be visible across London. The arch is illuminated by rings of six 400 W metal halide floodlights at 10 m intervals.

Power supply

“The biggest test for the stadium’s electrical system will come when Wembley hosts a night-time event in the heat of summer,” says Leon Higgins, divisional director of services designer Mott MacDonald Group.

When it does, the stadium will need all its 18.5 MVA power supply to keep the lighting, catering, life-safety, heating, ventilating, air-conditioning, cooling and other power requirements running. Eight large restaurants form a major component of this demand.

The venue’s power is delivered through a combination of high- and low-voltage electrics. High-voltage power is supplied from the grid through two primary substations: one has two 10 MVA feeds; the other has an auxiliary 7.5 MVA feed. If one primary mains supply should fail, the second supply will enable an event to continue regardless.

Reliability of power supply is critical for the stadium for both crowd safety and to ensure continuous TV coverage. If there is a problem, electrical loads are shed progressively to match the power available from the grid. In addition, the floodlights and power for television outside-broadcast vehicles are both backed up with a UPS.

“If we lose power, the viewers watching TV wouldn’t know,” says Higgins.

Fire engineering

“It was impossible for a unique building like Wembley to meet the evacuation times stated in the building regulations, which makes designing for fire safety a real challenge,” says Leon Higgins, divisional director of services designer Mott MacDonald.

As a result, the designers followed a fire-engineered solution. The shape of the stadium was one of the biggest challenges. “Not only is it circular, but it is shaped like a wine glass, so putting vertical shafts into the building is pretty tricky,” explains Higgins.

To deal with the problem of the building’s shape, the scheme was designed to enable the fire brigade to take fire tenders into the basement to tackle a fire. This solution was only possible because Wembley’s basement incorporates a giant underground ring road below pitch level. The road has been installed primarily for deliveries to the stadium’s retail and catering outlets, and to enable players and VIPs to access the stadium away from the public. It will also provide a subterranean location for outside broadcast vehicles to link up to TV services (see ‘Information backbone’).

Above ground, the stadium’s broad circulation concourses are designated “places of relative safety” for the spectators. These concourses are also home to more than 50 catering kiosks, complete with cooking facilities. All kiosks have fire shutters, and designed in is a smoke ventilation route from the kiosks through the façade.

Heating, cooling and watering

In addition to hosting the world’s most famous football cup final, the new Wembley is also a conference, exhibition and dining venue. The stadium has eight separate restaurants and more than 60 pitch-side hospitality suites.

Mott MacDonald opted for a centralised plant solution for servicing the stadium. Key spaces, such as the conference and dining venues, operate independently, while a boost fresh-air supply is also available.

To match variations in the load profile between large sporting and smaller corporate events, the cooling system has a variety of centrifugal and screw water chillers. Fully modulating gas boilers complement the design of the cooling system. Both the chilled water and heating systems use variable- speed pumping to match demand and save pump energy. The pitch-side hospitality suites are heated and cooled using a three-pipe VRV system.

The complexity of stadium operation and the variety of specialist systems installed necessitated a control system that could interface with the various sub-controllers and allow calendar-based event programming. Control of the mechanical services uses distributed intelligent controllers linked through a transmission control protocol/internet protocol data network. All controllers incorporate local UPS systems.

When you consider there are more than 2,500 WCs, 12 commercial kitchens – including the largest kitchen in London – and more than 50 food and beverage outlets on the public concourses, the provision of a safe hot-and-cold water supply is critical.

Early in the scheme’s design, Mott MacDonald had to come up with a solution for possible loss of mains water. To reduce consumption time-and-movement detectors control urinal flushing and infrared taps are installed. The consultant’s analysis of peak water consumption revealed a requirement for more than 600,000 litres of stored water. To avoid risks with water-borne bacterial growth, the distribution system is treated with chlorine dioxide, which removes the need for routine drain-down and chlorination between events.

Information backbone

In an environment where the safety of large numbers of people is the key priority, gathering and presenting information clearly and accurately is essential. The solution at Wembley is to use a common cable infrastructure to support fire safety, security, operations, retail and entertainment needs.

The infrastructure is based on fibre optics and Category 6 structured cabling to connect all parts of the stadium. A total of 72 separate data hubs are used to ensure the multi-gigabyte network supports the following services:

- High-resolution colour CCTV streaming of cameras

- Public address multi-channel audio transmission

- Voiceover internet protocol telephony with 802.3 af power over ethernet

- Building and security management systems

- Ticketing and crowd monitoring

- Retail point-of-sale systems

- Operational and business systems

The audiovisual system includes two giant 14 x 8 m LED video screens within the stadium bowl to enable spectators to see a close-up of the action. TV monitors are located throughout the public circulation and hospitality areas so that spectators can be informed and entertained.

A quality audio system is in place. The system has been designed with full concert quality output so that the stadium can be used to host concerts without the need for additional speakers. The system uses digital routing and processing to enable paging and multimedia presentations, as well as high-powered concert sound augmentation.

The designers took an ‘acoustic fingerprint’ of the old Wembley and, by using a computer radiance model, have replicated the fingerprint by acoustically treating the stadium’s bowl and roof.

In addition to public facilities, each of the 400 press seats that straddle the north side of the pitch’s centre line are fitted with data connections, telephony and video monitoring.

There is also an underground compound set aside on the stadium's circular access road beneath the building for broadcasters’ articulated production trucks and ancillary support vehicles.

At the heart of the broadcaster compound is a dedicated ‘patching centre’ that connects to all camera positions, the two pitch-view TV studios, 10 radio commentary booths and a dedicated radio production/engineering room.

Team sheet

Architect: Foster & Partners, HOK Sport

Structural, mechanical and electrical engineers: Mott MacDonald Group

Main contractor: Multiplex

Source

Building Sustainable Design

No comments yet