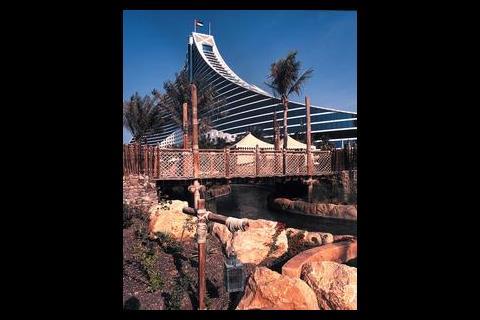

Inspired by the legend of Sinbad, Wild Wadi is a fully themed entertainment water park, designed to give the visitors the experience of a lifetime.

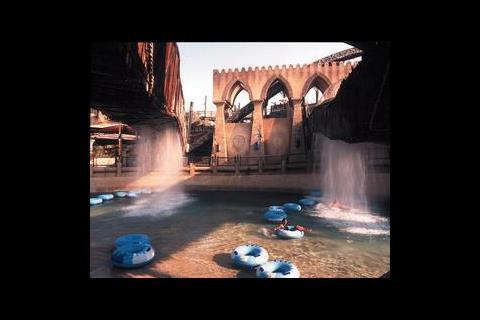

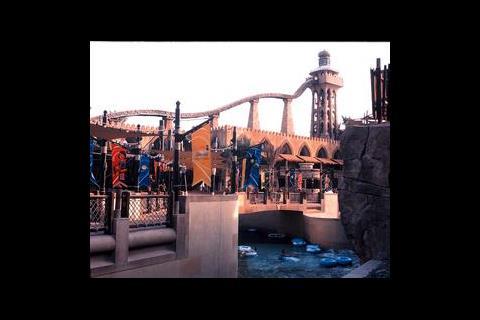

The aqua park consists of interconnecting flume rides, transporting guests around the park on rubber rings within an entirely themed environment, the style and concept of which has never before been seen in the Middle East. If placed end to end, these rides would stretch to incredible 2160 m.

Wild Wadi contains a constant 6·75 million litres of fresh water, with 7000 m³ being pumped around the park, at a rate of 50 000 m³/h. Ninety pumpsets are used to achieve this with an electrical load of 4 MW. While the park is effectively a closed circuit there are still ongoing water losses from backwashing and evaporation. The make-up requirement varies with environmental conditions but averages at around 1000 m³/week.

One of the potential problems encountered early on in the development was the amount of backwash water that would be consumed if conventional filters were used.

The solution was to use 13 diatomaceous earth filters on the various systems. These are made up of the fossil remains of diatoms, a type of algae that produces skeletons of amorphous (non-crystalline) silica. While this is more expensive than conventional filter media, it requires considerably less backwash water and is expected to provide a relatively quick payback.

Nevertheless, it was found that the volume of backwash water was still too much for the municipality sewer to handle in one go so it is backed-off into a storage tank to allow a controlled rate of discharge.

Each ride is constructed of glass fibre, the component parts being imported from America and slotted onto pre-positioned stilts and concreted routes. This process required a high level of liaison between the site team in Dubai, the ride designers in the UK and the American manufacturer of the fibreglass components – as the dimensions and positioning of each part had to be exact to ensure smooth connections. Extensive use was made of three-dimensional modelling in the design and some 3000 drawings were generated before the project was completed.

The design challenge of creating a natural look meant the visible areas are effectively an architectural skin that blends with the landscape and hides the engineering that makes it all work.

Steps have been taken to prevent burnt feet on the sun-baked concrete paths, with solenoid controlled sprinklers rising out of the ground to provide a 30 s spray of water every eight minutes, reducing the temperature of the paths through the subsequent evaporative cooling.

Sixteen of the rides are connected by one metre deep plunge pools, so that frolickers can change rides without having to leave the water - a real boon at the humidity experienced on most days. Water temperature is maintained at around 30°C all year round, using six reverse cycle heat pumps to provide 2·8 MW of summer cooling and 4·4 MW of winter heating.

Each ride offers visitors a different experience, from a relaxed trip down the Lazy River to the exhilaration of an uphill roller-coaster ride on one of the eight Master Blaster rides.

The individual rides also presented their own particular engineering requirements.

The Lazy River was perhaps the least demanding ride to set up, as it is essentially a slow moving body of water in a channel 585 m long and between 3 m and 4 m wide that takes visitors on a non-stop ride around the lower areas of the park. The one concern of the engineers was that the chlorine levels would dissipate along the length of the river. To avoid this, the river has a second treatment plant to top up the chlorine levels if required.

With the other rides, the key to the design is getting the water to behave in the right way. The Master Blasters, for example, are designed to shoot a raft uphill at very high speeds, in a roller coaster fashion. This is achieved by discharging water through nozzles at 270 m³/h for the standard rides and 545 m³/h for the family Master Blaster, that takes four people per raft.

The Action River is very different from the Lazy River, with a 150 m canyon that is prone to sudden bursts of fast-moving water which create standing waves. The waves are created from a 900 m³ tank at the top of the ride that discharges through hidden culverts onto the surface of the ride. Pumps at the bottom of the ride draw water back to the tank and hydraulic gates are used to hold back the water until the head reaches 8 m.

There are two surfing rides, Body-board Point Break Flow Rider and Body-board Beach Break Flow Rider – both the first to be seen in the Middle East. These use a separate compartment in the storage tank, fitted with fast-acting hydraulically driven gates on a plc time controller. At 40 s intervals the gates open to release a slug of water that is driven over curved foam surfaces to create perfect surfing waves.

A choice of 24 rides with differing characteristics ensures that every visitor can find something to enjoy.

Having been shipwrecked in a storm, Sinbad and his companions are said to have been washed up on a breathtaking tropical paradise where they created sophisticated tunnels and slides among the streams, so the children could enjoy a series of fast flowing rides and waterfalls. Many years later, a combination of imagination, concrete, fiberglass and engineering innovation has brought the legend to life.

Source

Building Sustainable Design