The team behind the retrofit of an Edwardian property using Passivhaus principles explain the significance of the high performance windows

The arrival of the windows on site means that we can begin to complete the building envelope at 64 Midmoor Road. We began with the installation of the front windows which have been made as replica timber sliding sashes, returning the font elevation to its original arrangement - an approach which contrasts to many of the neighbours that have gone down the UPVC route.

The new sashes have a good overall U-value of 2W/m2K, mainly thanks to the double glazed units that have a centre pane U-value of 1.5 W/m2K in spite of their slim (12mm thick) construction. Crucially they have been carefully detailed to be virtually airtight when locked closed. Each window has two compression gaskets at the top (or bottom) and four seals along its sliding edge. K&D joinery who manufactured the windows worked with us in the design development for these details.

The windows were tested for air tightness when we conducted the main site test last month. By covering each window with polythene, we were able to isolate the windows during the process and determine the air tightness for the building alone. Then, by cutting the polythene and taking new readings, we were able to determine the leakage rate of the windows themselves.

As the house is situated within a hundred metres or so of a conservation area, there was some sensitivity about the works in general

This indicated a problem with the meeting rails and K&D replaced the brush seals with slightly thicker ones. When we carried out the second air test in the same manner we were able to conclude that the windows were now almost completely airtight - perhaps with a total leakage of around 0.05 air changes per hour at 50 Pa.

Now some of you may be wondering why we didn’t pursue a lower U-value. Well, ideally we would have done, but we wanted to enhance the handsome front elevation and gain some favour with the planning authority for the more extreme work that we had planned at the rear of the property.

Also, as the house is situated within a hundred metres or so of a conservation area, there was some sensitivity about the works in general. The use of double glazed sashes within this conservation area is a bit of a no-no and we wanted to demonstrate that a high level of performance can be combined with fine detailing similar to the original sashes. If our project could be used to convince the local conservationists, then that would a positive outcome at a local level.

As for improving performance further, we hope to work with K&D on refinements to this sash design in the future to reduce the U-value substantially more.

At the rear of the house we have followed a stricter approach to U-values, combining 280mm of expanded polystyrene external insulation with triple glazed timber windows. This was especially important as the wall area and number of windows was much greater.

Importantly, the opening casements have double seals that seal tight when the multipoint espagnolette is locked down

There are now a number of triple glazed windows systems available in the UK. Our choice was based on a performance to cost rating and we chose the ’Eco-Passive’ range supplied by the Green Building Store.

The glazing units have a U-value of 0.6W/m2K, low conductivity glazing bars and thermally broken frames, giving an overall U-value of 0.8W/m2K-0.9W/m2K, putting them in real Passivhaus territory.

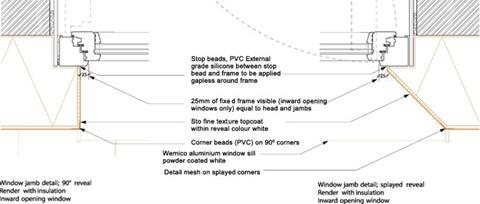

Importantly, the opening casements have double seals that seal tight when the multipoint espagnolette is locked down. The windows open inwards European style and use a tilt/turn mechanism that allows them to operate as a convention hinged casement or be tilted inwards from the top for night ventilation.

The choice to go with inward openers was partly driven by the options available from this manufacturer and partly by the superior thermal bridge detailing at the edge permitted by an inward opening system.

The triple glazed windows have been installed within plywood box linings that were fitted within the structural openings some time ago. This method provided a number of advantages:

- By fitting the plywood boxes first, precisely where we wanted them in the rooms, we were then able to take accurate dimensions for the real window sizes. In this way the boxes acted as templates.

- From a sequencing point of view we were able to create the aperture within the room and therefore complete lining works to each room, but delay window installation and therefore potential damage.

- The inside edge of the boxes was taped into the plasterworks or onto the internal air tightness layer, thus extending our air tightness barrier to where the window will be fitted. Oriented strand board formed a temporary security measure and allowed us to test the whole house for air tightness before the windows actually arrived on site (though we did need to seal the boxes with oriented strand board with silicone).

- The plywood linings have also allowed us to site the window just outside the original face of the wall in the same plane as the insulation. This has two benefits: an increased cill depth inside and a slightly reduced thermal bridge at the window edge.

The relationship between the window and the insulation has been considered too. In line with passivhaus detailing we have lapped the insulation over the timber frame of the triple glazed windows to reduce thermal bridging further, but we have also splayed this reveal to maximise daylight and sightlines. The insulation should be installed in the next couple of weeks and I hope to talk about that in the next blog.

Triple glazed windows on the rear elevation

No comments yet