When your project gets to the closing stages, a host of new subcontractors and delivery people appear on site. But how do you make sure some of those strangers aren’t there to rob you?

Thefts of plant and machinery are commonplace on construction sites.

But the final fit-out stage of a project can prove a bonanza for criminals.

Schemes may be on site for many months and, in that time, site security staff become familiar with faces and vehicles. But at the end of the project there is a sudden influx of new subcontractors, perhaps shopfitters or installers of white goods on housing developments. This can give both experienced and opportunist thieves easy access to a site – security guards may unwittingly allow criminals on to site as they do not have sufficient information about the new companies and staff who need access.

Recently, during the final stages of a two-year project to build 120 shops, retailers’ stock was delivered to site. Although procedures for the receipt of the goods – mostly expensive cosmetics – were followed by security personnel, crates of perfume were subsequently removed by thieves posing as shopfitters. The losses were in the region of £100,000 but, more importantly, the theft delayed the opening of the flagship store, which had an impact on profits and business reputation. If security staff had been properly briefed with specific details of the tenant’s contractor, this theft would almost certainly not have occurred.

An effective method to tackle such thefts is to obtain a thumbprint on the paperwork whenever goods are released. This serves as a deterrent to would-be thieves and as tangible evidence for the police in the event of a theft.

The majority of thefts during the fit-out period occur at the delivery point, before products reach the installation location. “Round the corner” scams – where delivery drivers are redirected to a different section of the site or to another site, then duped into handing over their load to the criminals – are not uncommon.

So, security for the final phase of a project must be planned and managed carefully. Project managers need to liaise closely with site supervisors and security providers in order to efficiently manage the influx of tradespeople and related service providers. Specific tasks should be delegated to site supervisors, in order to avoid the “it wasn’t my job” culture.

Access control and personnel management is vital. Up-to-date lists of authorised personnel and agency staff should be kept. This can be problematic, but it can be managed through continual liaison between site management and service providers. Photographs of new contractors could be taken, along with company details, to provide a reference database. All personal information must be handled in accordance with Data Protection Act guidelines, however.

In ‘round the corner’ scams, delivery drivers are redirected to another site and duped into handing over their load to the criminals

Vehicle details should be recorded, with numberplate details confirmed against tax discs. A search policy should be in place and planned and random searches of vehicles, equipment and personal belongings must be conducted regularly by a security team.

Sites should have a robust badging system with numbered badges clearly showing areas of access and dates of validity.

To allow easy identification, authorised personnel can wear colour-coded and numbered vests, armbands or hard hats that correspond to their working area (numbers and colours are required to accommodate those who may be colourblind). If an electronic system is installed, access cards should be zoned to prevent unauthorised movements of personnel. Those found outside of their working area should be challenged by security personnel or managers.

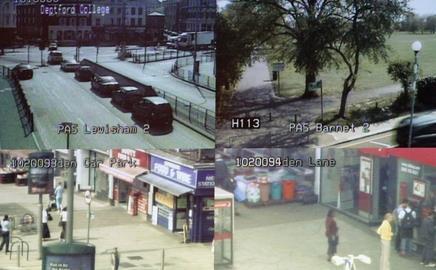

Other solutions may be more high-tech. Radio frequency identification (RFID) and covert electronic tracking devices can play a significant role in tracking products and ensuring correct deliveries. Security systems such as wireless CCTV and perimeter detection systems can be quickly and easily installed at a site, improving surveillance and detection possibilities.

However, these systems need to be proportionate and scalable. To justify the initial capital outlay, they should also be portable for use on different sites. Making personnel aware that these measures are in place through good signage will also act as a deterrent to many.

The weakness of all these measures is that they all rely on human input. We know that a proportion of construction site crime is committed by people in the industry, exacerbated by apathy and a lack of interest in security needs among senior managers.

It is vital that security policies be driven from board level. At an operational level, it is the site manager’s responsibility to ensure personnel are aware of their security obligations and to implement robust procedures to manage the delivery and release of products and material.

Postscript

Gavin McCormick is special projects manager at security and risk specialist Linx International

No comments yet