Glass rainscreen cladding is an established and proven type of facade. This CPD, sponsored by Sto, explores how the robust and secure system offers design flexibility, thermal efficient insulation and a facade that is weather resistant

How to take this module

UBM’s CPD distance-learning programme is open to anyone seeking to develop their knowledge and skills. Each module also offers members of professional institutions an opportunity to earn between 30 and 90 minutes of credits towards their annual CPD requirement.

This article is accredited by the CPD Certification Service. To earn CPD credits, read the article and then click the link below to complete your details and answer the questions. You will receive your results instantly, and if all the questions are correctly answered, you will be able to download your CPD certificate straight away.

CPD CREDITS: 60 MINUTES

DEADLINE: 18 AUGUST 2017

![]()

INTRODUCTION

Rainscreen cladding is a form of double-wall construction, in common usage since the 1970s. The outer layer keeps most of the rain out. A drained and ventilated cavity eliminates the remainder of the moisture by natural drainage and evaporation. The inner leaf provides thermal insulation, prevents excessive air leakage and carries the wind load.

There are two main types of non-structural glass systems: rainscreen cladding, and curtain walling. Curtain walling consists of an aluminium-framed wall, which is attached to a building structure. The frame can have glass, metal panels or thin stone inserted within the frame.

This framed wall prevents any weather from penetrating through to the building.

Rainscreen cladding consists of glass-faced composite panels, thermal insulation and the sub-construction. Open joints between the panels allow a circulating air layer to be formed between the hung panels and the thermal insulation, which is mounted directly on to a building structure.

This CPD will focus on glass rainscreen systems.

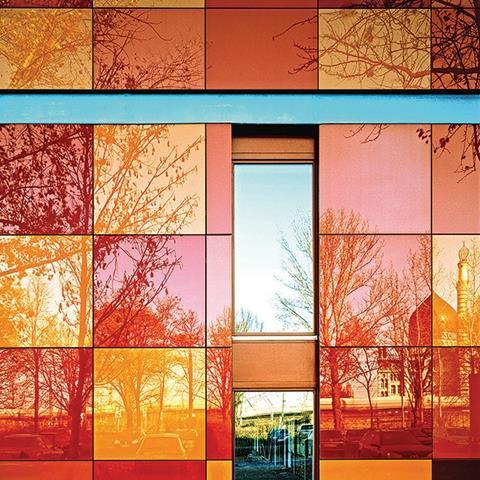

Glass rainscreen cladding systems are an established and proven type of facade, offering huge design flexibility with choices in shape, texture, material type and colour. They are robust, secure and can make a significant contribution towards energy-efficient structures and comfortable, healthy indoor environments.

The sub-construction is a combination of stainless steel wall brackets, aluminium T-profiles and horizontal rails – detailed correctly, this eliminates cold bridging. Insulation on the outside of the construction keeps the wall warm and reduces the risk of condensation and minimises temperature fluctuations.

This breathable system offers thermally efficient insulation, minimising the cost of heating and air-conditioning, while the structural frame of the building stays warm and dry.

They also offer protection from moisture, because interstitial condensation is restricted to the cavity, which can reduce or eliminate internal damp and mould. Rainscreen cladding systems are simple and quick to install in any season, and no wet trades are required.

SYSTEM COMPONENTS

The build-up of a typical rainscreen cladding system is:

- A decorative panel to resist the weather. This can be made from glass, stone, metal or rendered board

- A support structure to carry the panel system, usually aluminium and stainless steel.

- Insulation surrounding the brackets and insulating the substrate. Mineral fibre is the most commonly used type.

Aluminium is an ideal material for rainscreen cladding systems because of its high strength-to-weight ratio and low comparative cost, but stainless steel offers better thermal performance. Stainless steel brackets can achieve the same U-value as aluminium with just over half of the thickness of the insulation layer, without thermal breaks. Therefore a combination of aluminium rails and stainless steel brackets can optimise both performance and cost.

The number of brackets required will depend on wind loads, the properties of the substrate and the depth of the system. Additional fixed-point brackets may be necessary to carry the weight of the system, particularly on low-strength substrates, such as lightweight blockwork, wood or light-gauge steel.

In a glass rainscreen cladding system, the outer leaf panels can be made of solid glass, laminated glass or toughened glass. Toughened glass is four to five times more durable than standard glass, breaks into smaller, safer fragments and stays safely bonded to backing board even when shattered.

To toughen glass, glass is heated and rapidly cooled. The risk is that this locks in nickel sulphide impurities, which can expand when heated, causing shattered panes.

The solution is to use heat soak testing, where toughened glass is reheated to shatter panes with high concentrations of NiS bubbles. This reduces the risk of shattering from 1 in 4,000 to 1 in 40,000 within 20-30 years.

DESIGN CONSIDERATIONS

Different glass panel sizes are available to suit project requirements, and can be shaped before the toughening process into a great variety of forms. This allows better control of grids, lines, joints and recesses as a design element. Once the glass has been toughened, panels cannot be cut again. Colours, if required, are fused to the back of the glass, melting at >600°C. Because the colour is not a paint or a coating, it is permanent, cannot be damaged and does not fade when exposed to UV light. Graphics can be fused to the back of the glass in the same way. A reflective coating can also be applied to the glass.

Thermal performance

Cold bridges can be eliminated if the correct components are specified. With correct detailing of the insulation layer, thermal bridges can be eliminated or minimised and the target U-value achieved.

Fire breaks

Rainscreen cladding systems should be designed in accordance with British standard BS 8414-1:2015, Fire performance of external cladding systems. Test method for non-loadbearing external cladding systems applied to the masonry face of a building.

For buildings of more than 18 metres in height, the cladding system should prevent fire from spreading from floor to floor. To achieve this, continuous horizontal firebreaks are required between the second and third storeys and every storey thereafter. Vertical firebreaks may be required to provide fire compartmentalisation between adjoining rooms. Cavity firebreaks are needed to close the cavity at all openings such as windows and doors. The cavity should contain nothing that could contribute to a fire load. The number and location of firebreaks should meet fire officer/Building Control specifications. Specifiers should consider consulting a specialist firebreak system supplier.

Wind loads

Wind load is often the largest force applied to a facade, varying with the size, shape and location of the building. The corners of buildings – called “rim zones” – attract the highest wind loads. Special attention should be paid to such zones, where negative loads can create significant suction. The number of fixings required is directly related to the wind load calculations and the substrate pull-out capacity.

Wind load calculations should be carried out by a competent structural engineer, in accordance with BS EN 1991-1-4:2005+A1:2010, also known as Eurocode 1. The load imposed on a building can be positive (pushing) or negative (suction). For rainscreen cladding, negative loads are calculated. It is important that the fixing method can withstand the imposed loads. The pull-out capacity is the strength of the substrate in relation to how it holds a restraining fixing. Pull-out tests are carried out to ensure that each fixing has a sufficient load-carrying capacity.

TESTING PROGRAMMES

The British Board of Agrément (BBA) is a UK body that issues certificates for construction products. BBA approval applies to the whole of a system, whether it is used for new buildings or refurbishment.

It provides a “fit for use” confirmation, provided the system is installed, used and maintained as set out in the certificate. The BBA tests all aspects of a system against all relevant criteria and design considerations. In general, industry bodies such as the National House Building Council (NHBC) will not recommend a system that does not have BBA approval.

BBA approval indicates compliance with Building Regulations and NHBC standards, and determines the expected service life. For rainscreen cladding and external wall insulation, this is typically 30 years.

Other relevant standards include the Standard for systemised building envelopes published by the Centre for Window and Cladding Technology (CWCT), widely considered the authority on such systems in the UK. This covers weather tightness, loading and movement, thermal and moisture performance, acoustics, fire performance, operable components, safety and service life. CWCT publishes more than 90 technical notes relevant to glass or rainscreen cladding.

Both building specification service NBS and NHBC refer to its technical notes within their own guidelines. For example, NHBC Part 6 Chapter 6.9, Standard for walls with ventilated rainscreen and NBS Section H92 – Rainscreen cladding are based on the CWCT standard.

How to take this module

UBM’s CPD distance-learning programme is open to anyone seeking to develop their knowledge and skills. Each module also offers members of professional institutions an opportunity to earn between 30 and 90 minutes of credits towards their annual CPD requirement.

This article is accredited by the CPD Certification Service. To earn CPD credits, read the article and then click the link below to complete your details and answer the questions. You will receive your results instantly, and if all the questions are correctly answered, you will be able to download your CPD certificate straight away.

CPD CREDITS: 60 MINUTES

DEADLINE: 18 AUGUST 2017

Privacy policy

Information you supply to UBM Information Ltd may be used for publication and also to provide you with information about our products or services in the form of direct marketing by email, telephone, fax or post. Information may also be made available to third parties. UBM Information Ltd may send updates about Building CPD and other relevant UBM products and services. By providing your email address you consent to being contacted by email by UBM Information Ltd or other third parties. If at any time you no longer wish to receive anything from UBM Information Ltd or to have your data made available to third parties, contact the Data Protection Coordinator, UBM Information Ltd, FREEPOST LON 15637, Tonbridge, TN9 1BR, Freephone 0800 279 0357 or email ubmidpa@ubm.com. View our full privacy policy at www.building.co.uk/cpd

1 Readers' comment