Sponsored by URSA, this module looks at rainscreen systems, with a focus on the pivotal role of insulation. It also explores how early engagement with manufacturers can help designers to specify compliant products within the new building safety regime – and meet demanding thermal and acoustic performance requirements

In this module, we will focus on how insulation works within rainscreen systems.

Learning objectives

- Understand the different components of a rainscreen system, their role and how they contribute to the performance of the wider system.

- Understand the influence that performance considerations – including thermal conductivity, acoustics, fire safety and durability – have on insulation specification within a rainscreen system.

- Gain a clear understanding of the regulations that inform the specification of insulation within rainscreen systems.

From humble origins to modern multilayered facade systems

The origins of rainscreen systems can be traced back to northern Europe, where builders observed long ago that creating walls with inner and outer layers proved an effective way to protect buildings from driving rain and wind. Early stone and timber structures often used layered construction in which rainwater was deflected or drained before it could penetrate to the interior.

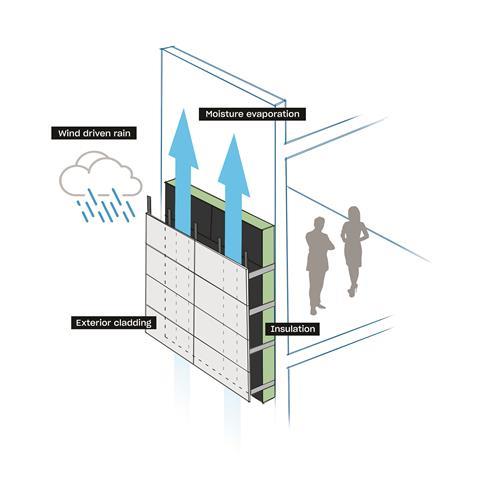

In the mid 20th century, Norwegian architects and engineers studied these vernacular traditions and began to formalise what became known as the rainscreen principle. Their findings were reinforced by groundbreaking academic research published in 1963 by the National Research Council of Canada, titled Rain Penetration and its Control. This research showed how creating a ventilated cavity behind the cladding panels significantly reduced moisture ingress by allowing incidental moisture to drain and evaporate.

Since then, rainscreen systems have evolved significantly. What began as simple timber facades with air gaps have become highly engineered assemblies with multiple layers – cladding, substructures, insulation, membranes and cavity barriers. Today’s rainscreen systems are not just about keeping water out; they can play a central role in buildings’ thermal and acoustic performance.

What is a rainscreen system?

A rainscreen system is a type of building envelope designed to control moisture, provide weather resistance and enhance thermal and acoustic performance. It consists of:

- An outer cladding layer, which can be metal, timber, ceramic, cement or stone panels supported by a bracket system, or a masonry outer leaf

- A ventilated cavity

- An inner wall construction that includes insulation.

![IMG_4168[66]](https://d3sux4fmh2nu8u.cloudfront.net/Pictures/480xAny/9/9/3/2016993_img_416866_997662.jpeg)

The genius of a rainscreen system lies in its layered approach. Each component plays a role, but it is only when they work together that the system achieves its full potential: keeping the building dry, regulating temperature, improving occupant comfort and extending the durability of the building.

The outer cladding layer provides the first line of defence, deflecting most rain while allowing architectural expression. The cladding panels are supported by a substructure, typically aluminium or steel rails and brackets, which anchors the cladding to the building while transferring loads.

Behind this lies a cavity – either ventilated or drained and back-ventilated – designed to equalise pressure, allow air flow and safely direct any water ingress away from the building.

Behind the cavity is the insulation, which not only improves thermal efficiency but can also contribute to acoustic comfort and fire performance. A weather-resistive or breather membrane then protects the inner structure. Additional components may include sheathing boards, vapour control membranes and cavity barriers. These have different parts to play – providing support, regulating condensation and improving acoustic performance.

Glass mineral wool is a material suitable for use as insulation in rainscreen systems due to its thermal and acoustic properties and fire classification. (It is deemed non-combustible with a fire classification of Euroclass A1 when tested to EN 13501-1:2018 Reaction to fire.)

Specifying insulation in rainscreen systems

Once specifiers understand the anatomy of a rainscreen system, they must navigate a series of design considerations that will determine how that system will perform in practice. The building’s height, intended use, occupancy type, performance targets, aesthetic ambition and regulatory obligations all intersect to shape design and specification decisions.

For example, buildings above 18m tall in England and Wales or 11m in Scotland are subject to bans on combustible materials, meaning that insulation and cladding must be non-combustible or pass rigorous large-scale testing under BS 8414. Healthcare or educational facilities, meanwhile, may place particular emphasis on acoustic performance, requiring insulation with proven sound attenuation properties.

Thermal performance is a key driver in modern construction. The updated Building Regulations Approved Document Part L demand lower U-values and enhanced building fabric performance, which means specifiers must carefully consider the thickness and thermal conductivity of insulation. At the same time, thermal bridging – particularly through metal fixings and brackets – must be mitigated to ensure the rainscreen system performs as designed. Conventions for U-Value Calculations (BRE 443: 2019) explains in detail how to factor in the thermal bridges caused by metal brackets when calculating U-values.

Durability and maintenance also come into play. In a rainscreen system, the insulation must be able to withstand exposure to moisture without degradation, while the system as a whole must allow for inspection, drainage and long-term stability.

Thermal performance

The thermal efficiency of the building envelope is measured in terms of U-value (defined in watts per square metre per kelvin or W/m²K), which indicates how effectively an element of the building envelope prevents heat from transferring through it from inside to outside. Different organisations like the Passivhaus Institut and LETI have set their own target U-values for the fabric of new-builds, while government regulations have also set increasingly tough U-value standards for building fabric as part of the move towards net zero.

Approved Document L of the Building Regulations in England, and the equivalent standards in the devolved nations, sets minimum energy performance benchmarks for walls, windows and roofs. For both new dwellings and buildings other than dwellings the maximum U-value for external walls is 0.26W/m²K. However, designers usually work towards the target/notional value of 0.18W/m²K, because hitting this lower target will typically be necessary if the building as a whole is going to meet whole-building energy targets.

Achieving these values in practice requires continuous insulation across the facade and reducing thermal bridging. Glass mineral wool insulation can be a good choice within rainscreen cavities because it is dimensionally stable and non-hygroscopic, which means it maintains its performance over time. Insulation manufacturers can work with designers to assess the specific requirements for insulation on their projects and support them with U-value calculations using their products.

Overcoming thermal bridging

Thermal bridging remains a particular challenge in rainscreen systems. Metal brackets can bypass insulation layers, creating localised heat loss. Therefore the choice between the specification of aluminium, standard steel and stainless-steel brackets can have a significant impact on the thermal performance of the rainscreen system. Solutions include the use of thermal breaks at fixing points and careful placement of insulation to wrap around penetrations.

Moisture control

While rainscreens are primarily designed to shed external moisture, condensation poses a longer-term risk. When warm, humid indoor air migrates through the building envelope and meets colder surfaces within the facade, interstitial condensation can form. If unmanaged, this can lead to mould growth, corrosion of fixings or long-term degradation of insulation.

Glass mineral wool insulation can play a valuable role here, offering vapour permeability that allows any incidental moisture to dissipate rather than becoming trapped. At the same time, its water-repellent treatment ensures that bulk water does not compromise thermal performance. Careful detailing of vapour control layers, combined with ventilated cavities that promote drying, reduces the risk of condensation accumulating unseen within the wall.

The Building Regulations require designers to assess condensation risk using methods such as the Glaser calculation. However, real-world performance often depends on site workmanship as much as design. Ensuring continuity of vapour barriers at junctions, sealing around penetrations and avoiding blocked ventilation paths are all essential to maintaining a dry, durable rainscreen facade. By considering thermal performance alongside condensation-control solutions at early design stages, specifiers can ensure buildings can meet energy performance targets and regulatory compliance. For that matter, insulation manufacturers can work with designers to assess the expected conditions of use of the building and its location to run condensation risk analysis (CRA) for particular sections of the building envelope.

Acoustic considerations

Noise is increasingly recognised as another key determinant of occupant wellbeing, particularly in urban environments where traffic, rail and aircraft noise can all be an issue. Requirements for acoustic performance of buildings are set out in Part E of Building Regulations in England and Wales and in the Technical Handbook Section 5 in Scotland. Rainscreen facades, by virtue of their multilayered design, can offer a valuable opportunity to enhance acoustic comfort if insulation is carefully specified.

Glass mineral wool insulation provides sound absorption and can reduce external noise transmission into internal spaces. When installed continuously across the facade and combined with well-sealed air- and vapour-control layers, such insulation can help achieve sound reduction values that will contribute to a comfortable internal environment. For schools and healthcare buildings, this can mean improved concentration, reduced stress and better recovery outcomes, while for residential projects it enhances quality of life.

The depth of insulation, the continuity of the cavity and the detailing around penetrations and junctions all influence acoustic outcomes. Where even higher acoustic performance is needed, rainscreens can be combined with resilient internal linings or secondary glazing strategies to form part of a holistic noise-control approach. Ultimately, acoustic considerations should not be treated as secondary to thermal performance, but as an integral design factor. Early dialogue with manufacturers can ensure that the selected rainscreen insulation addresses all considerations simultaneously.

Fire performance

No issue has shaped the rainscreen insulation market more in recent years than fire safety. The Grenfell Tower tragedy in 2017 fundamentally altered expectations, regulation and accountability, particularly in high-rise residential construction. For rainscreen facades, fire performance hinges on three factors: the combustibility of materials, the containment of fire spread through cavities, and the evidence for system behaviour in real fire scenarios.

Glass mineral wool is a material suitable for use as insulation in rainscreen systems due to its thermal and acoustic properties and fire classification. A typical glass mineral insulation product is deemed non-combustible with a fire classification of Euroclass A1 when tested to EN 13501-1:2018 Reaction to fire. Always refer to the manufacturer for fire classifications of their products.

Insulation, fixings, membranes, cladding and cavity barriers interact in complex ways during a fire. For that reason, rainscreen systems that are going to be used in certain situations now require special fire testing using the BS 8414 test method, which evaluates a full rainscreen wall under realistic fire conditions. However, systems that are made entirely from components that are all classified as non-combustible do not need to undergo this testing. For designers, the critical point is that compliance is judged not on individual components in isolation but on the performance of the entire wall build-up.

The Building Safety Act 2022 has heightened accountability, requiring principal designers and contractors to maintain evidence of compliance. System test reports, along with detailed records of specified materials, now form part of the digital “golden thread” of building information. This shift places greater emphasis than ever on early engagement with manufacturers, who can provide documentation of test results and guide design choices towards proven combinations.

It is worth looking out for companies that comply with the Code for Construction Product Information (CCPI). This is a voluntary code of practice covering product information such as technical datasheets, brochures, websites, BIM objects, CE/UKCA marking and declarations of performance, installation guides and test certificates. It is designed to ensure all such materials are clear, accurate, accessible, up-to-date and unambiguous. The code was developed after Grenfell to support building safety, regulatory compliance and trust in the construction product supply chain.

The importance of engaging with manufacturers early

Given the updated regulatory landscape and the complex nature of rainscreens themselves, the value of involving manufacturers at the earliest design stages cannot be overstated. Every project has unique conditions: climate, height, occupancy, budget and aesthetic requirements. Manufacturers provide not only technical data but also deep knowledge of how products perform within systems, how they interact with membranes and substructures, and how they have been tested.

By consulting with manufacturers early, specifiers can avoid the costly pitfall of late-stage redesigns, where non-compliant materials must be substituted at short notice. They can also access system-specific guidance that ensures thermal performance, acoustic performance and durability are achieved without compromise. Importantly, engaging with manufacturers creates a clear audit trail that demonstrates due diligence – an increasingly critical aspect under the Building Safety Act.

This collaboration also enables architects and contractors to move beyond compliance and towards best practice, specifying rainscreen systems that are not only legally sound but also optimised for design performance.

Final thoughts

In today’s built environment, rainscreen systems have proven to be more than an aesthetic solution. From their origins in early moisture-control research to modern multilayered assemblies, rainscreen systems have come to offer design flexibility while helping to meet targets on thermal, acoustic and fire-safety performance.

Navigating the revisions to the Building Regulations and standards requires technical clarity and proactive engagement with specialist manufacturers. By collaborating early, architects and contractors can ensure they specify rainscreen solutions that elevate occupant wellbeing, reduce risk and streamline approval.

Please fill out the form below to complete the module and receive your certificate.