Sponsored by LABC Warranty, this module looks at the culture change required for an organisation to embrace timber-framed construction

Learning outcomes

- Understand what is involved in timber-framed construction.

- Identify the benefits and risks of timber-framed construction.

- Recognise the culture change needed for an organisation to successfully adopt timber-framed construction.

Timber frame as a modern method of construction

Timber-framed construction is classed as a modern method of construction (MMC) – a collective term for innovative building techniques designed to improve efficiency, quality, and sustainability compared with traditional brick and block methods. MMC approaches share a common feature: components are manufactured offsite in controlled factory environments, then transported to site for rapid assembly. There are seven different types of MMC covering everything from modular homes to 3D printing. Timber-framed systems fall within category 2: factory-made flat panels, including open-panel and closed-panel systems.

In this module we explore how organisations traditionally reliant on masonry construction can adapt their mindset, processes and skills to embrace timber-framed construction effectively.

Understanding timber-framed construction

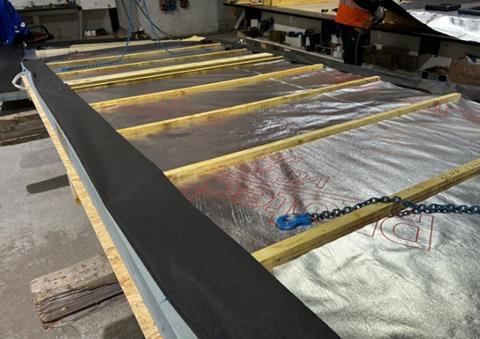

Timber-framed buildings are created using structural panels manufactured offsite. Open-panel systems comprise a structural timber frame and sheathing finished on site, while closed-panel systems arrive with insulation, membranes and sometimes services and windows pre-installed. Once delivered, the panels are assembled to create the building structure, with external cladding and internal finishes added on site. This precision-engineered approach allows consistency and quality control that are difficult to achieve through traditional site-based methods.

The benefits of timber-framed systems are well documented – and offer multiple advantages that align with modern housing objectives. They include:

- Accuracy of manufacture

- Efficiency of design, reducing or eliminating waste

- Certainty of cost through repetitive production

- Jigs and robots allowing the industry to address the skills shortage

- Increased output as housing demand escalates.

So that’s it, then… Job done… Silver bullet found?

Well, yes and no. There are still a few culture changes that need to be embraced before timber frame can truly deliver on its potential.

Cost: perception versus reality

At first glance, timber-framed construction may appear more expensive per unit than traditional brick and block. However, when full project efficiencies are considered, such as reduced preliminaries, and enhanced accuracy is factored in, the value proposition can change dramatically. The cheapest method for any project will depend on a whole host of variables, but quicker build times, early weathertightness and predictable quality can all deliver significant savings if the project team are willing to embrace a different way of working.

Design discipline and early collaboration

That new way of working means thinking ahead. A mindset where the kitchen needs to be ordered as the soleplate is positioned takes some adjustment for anyone used to working in the traditional way. But this shift in perspective is fundamental to unlocking the benefits of MMC.

Timber-framed construction thrives on precision and repetition. To achieve this, “design freeze” needs to be implemented as early as possible to prevent costly and disruptive structural revisions later. Designs should also standardise key dimensions and interfaces where possible without stifling architectural freedom. The greater the level of repetitive design, the more efficient the manufacturing process and the more predictable the outcome.

Early engagement between designers, manufacturers, warranty providers and site teams is essential. Traditional procurement models – where detailed design follows tender – can clash with MMC principles. Instead, collaborative approaches such as design for manufacture and assembly (DfMA) and early supply-chain involvement (at RIBA stage 2–3) can make the difference between success and frustration.

Regulatory and assurance landscape

As regulatory requirements evolve, timber systems must meet not only building regulations but also the expectations of warranty providers, mortgage lenders and insurers.

Closed-panel systems, cassette roof panels and engineered floor joists often fall outside the scope of the Building Regulations approved documents as they are not considered to be traditional construction, so compliance relies upon performance-based evidence including structural calculations, along with certification and testing for fire resistance. Robust reviews through schemes such as LABCW system acceptance or NHBC Accepts can provide confidence in the durability and quality of timber systems.

Managing risk: fire, moisture and durability

Timber is a natural material that offers strength and sustainability but also some vulnerabilities. Timber construction is standard in many parts of the world, but in the UK cultural hesitancy – mainly centred around combustibility, weathering and longevity – still influences decision-making.

Fire performance is often misunderstood. It is important to recognise that, with the correct cavity-barrier detailing, factory quality assurance and certified fire-resistant linings, modern timber systems can meet demanding performance standards.

Similarly, moisture management is crucial in timber buildings, but correct sequencing, temporary weather protection during construction and airtightness testing can all play a part in mitigating the risk of trapped moisture. Data on warranty claims consistently shows that failures are rarely due to the material itself, but rather to poorly designed interfaces, poor sequencing or lack of understanding of the system. Training, competent supervision and a mindset of shared responsibility are vital to managing those risks. The LABC Warranty Technical Manual has guidance on all of this.

Logistics and site integration

Efficient logistics remain the backbone of any MMC project. Vehicle and crane movements, panel storage and installation sequencing all need to be considered from the earliest layout designs.

A well-designed site could, for example, serve eight plots from one crane mat rather than four, with a subsequent saving in time and cost.

A successful offsite build is one where the site feels calm and predictable, with just-in-time deliveries and minimal rework. To achieve this, planning and communication must be continuous – from the design team to the manufacturer and the site manager.

Payment terms aligned to factory production and stage completions, meanwhile, can improve cash flow and partnership confidence between builder and manufacturer.

Sustainability and the Future Homes Standard

Timber frame sits naturally within the sustainability agenda. As a renewable, carbon-sequestering material, timber contributes directly to reducing embodied carbon – a critical target under the Future Homes Standard. Precision manufacturing should also lead to less waste, better airtightness and improved thermal efficiency in use. These advantages not only support ESG goals and the Future Homes Standard, but also position timber as a cornerstone of the UK’s transition to low carbon housing. Looking ahead, circular economy principles may allow timber components to be recovered, reused or recycled at end-of-life, too – creating further environmental and economic value.

Competence and training

Cultural change depends on competence. Every participant in the project – from the architect to the crane operator – needs to understand how timber frame behaves, how it needs to be protected and how it should be maintained.

Site teams accustomed to masonry construction often underestimate the precision tolerances of timber systems. Awareness training, toolbox talks and manufacturer guidance are essential. The more informed the workforce, the fewer site errors, moisture risks and warranty issues will arise.

It is vital to work with timber-frame specialists certified under BM TRADA Q-Mark, Structural Timber Association members or other recognised quality schemes, and factories certified to ISO 9001, the international standard for quality management.

Operatives, supervisors and site managers should receive system-specific training and toolbox talks. Culture change is achieved when MMC competence becomes embedded across all teams, not just confined to a few champions.

Work quality plays as important a role in the success of timber-frame projects as it does in traditional construction. However, timber frame presents its own unique challenges. Management teams and operatives may lack familiarity with timber-frame systems unless they receive adequate training. These systems are often less forgiving than traditional methods, with limited or no scope for on-site adaptation. Even skilled operatives may find certain aspects of timber frame counterintuitive when working with these systems for the first time.

There are plenty of questions to ask: are all operatives suitably trained, or is this limited to a small number of supervisors? Are those managing the site suitably qualified or experienced with the system? Timber-based systems may be liable to shrinkage after their initial installation – have the operatives allowed for this, and is the site manager aware of it?

Principles associated with traditional construction are still relevant to timber frame buildings: cavity barriers, cavity trays, clean cavities and installation of gas membranes may raise issues on site that require a suitable solution. Are those managing the site aware of this, and are they adequately trained to understand the ramifications of incorrect detailing?

Training should not be confined to site staff: warranty inspectors, designers and clients all need exposure to timber-framed construction in order to be able to make informed, collaborative decisions.

Procuring timber frame

For commissioning organisations seeking to make a move into timber frame, organisational alignment is essential. Senior leadership must champion the change, and governance structures need to define accountability. Housing, procurement, technical and maintenance teams must co-ordinate. Pilots and phased adoption can help organisations learn and build confidence before scaling, because timber frame requires new skills and knowledge.

Staff across a whole range of roles need training on timber-frame systems, tolerances, factory quality processes, logistics and installation. Procurement teams must learn to specify and evaluate timber-frame providers. Upskilling is vital to reduce reliance on external expertise and embed timber-frame capability within the organisation. Timber-frame success relies on structured processes and feedback mechanisms. Each project should capture lessons learnt, analyse defects and feed knowledge into future procurements. Digital tools such as BIM can support traceability, while structured checklists and quality gates ensure consistency across design, factory and site stages.

Continuous improvement and innovation

To embed timber frame as a core delivery method, organisations must commit to continuous improvement. Each project presents an opportunity to collect data, measure performance and refine both technical design and delivery processes. Establishing robust feedback loops between site, factory and design teams ensures that lessons learnt translate directly into better outcomes on future schemes. This approach mirrors the manufacturing sector’s emphasis on incremental improvement and quality assurance, helping construction move closer to a right-first-time culture.

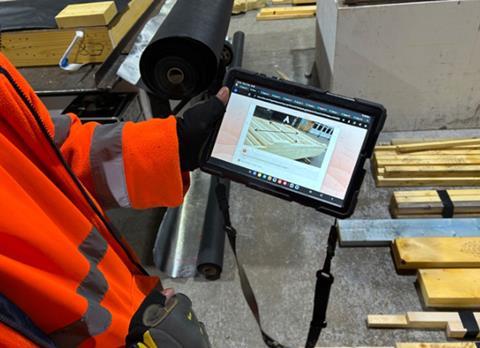

Digital tools are increasingly central to this transformation. BIM and digital twins enable real-time co-ordination between design, manufacturing and site assembly. Integrating 3D models with factory data allows tolerance checking, clash detection and visual verification long before components reach site. In the future, technologies such as AI-assisted inspection, drone surveying and digital quality-assurance platforms will further strengthen assurance processes and reduce reliance on subjective site inspections.

Warranty providers, such as LABC Warranty, are adapting their inspection and risk-assessment frameworks to reflect this shift. Digital evidence, photographic records and traceable material data can provide a robust audit trail to demonstrate compliance, durability, and performance. This not only reduces rework and cost but also builds confidence with lenders and insurers.

Conclusion

Timber frame can deliver low carbon, precision-built homes at scale, but success depends on more than the system itself: it demands a change in behaviour, mindset and process.

The adoption of timber frame is becoming widespread across the industry. Vistry, BarrattRedrow, Persimmon and Taylor Wimpey all have their own factories – multiple factories in some cases. This commitment will help to drive up timber frame usage in England from around 15% now to a predicted 30% or more within a few years. Scotland has always embraced timber frame, with approximately 90% of housingbuilding using this build format.

If we plan earlier, collaborate more openly, invest in competence, and embrace data-led assurance, timber frame can move from being a “modern method” to a “mainstream method” that is trusted, repeatable and integral to the future of UK housing.

Useful resources

LABC Warranty offers training in timber-framed construction and a whole host of other construction-related topics. Find out more here.

Please fill out the form below to complete the module and receive your certificate.