Structural fire resistance is crucial to the safety of buildings. This CPD, sponsored by Steel for Life, provides an overview of the performance of steel in fire, including key standards and fire resistance periods

CPD CREDITS: 90 MINUTES

DEADLINE: 16 MARCH 2018

For more information about UBM’s CPD distance-learning programme, click here

INTRODUCTION

Much is known about structural steelwork in fire. Rigorous testing, including full-scale building tests in the late 1990s, has led to the development of robust modelling and analytical techniques that are subject to constant refinement. Fire protection accounts for approximately 10-15% of the cost of a steel frame for a typical multi-storey commercial building.

This CPD provides an introduction to fire protection of new steel-framed buildings. It will provide an overview of the performance of steel in fire, legislation and standards on fire resistance, fire resistance periods and fire protection options for steel-framed buildings.

CARDINGTON FIRE TESTS

In the late 1990s, a series of full-scale fire tests were carried out on an eight-storey steel-framed building with composite steel deck floors at the BRE’s Cardington facility. Observations from the Cardington fire tests and other large building

fires have shown that the behaviour of the composite steel deck floor plays a crucial role in providing inherent fire resistance when compared to tests on isolated construction elements. The fire tests demonstrated that the slab acts as a membrane supported by the perimeter beams and protected columns.

STEEL SECTIONS IN FIRE

All hot-rolled structural steel sections have some inherent fire resistance. This is a function of the size of the section, the degree of exposure to the fire and the load that the section carries. Fire resistance is usually measured in relation to the ability of the structural section to survive in a standard fire test as described in BS 476-20, BS ISO 834 and BS EN 1363-1. This test takes place in an approved furnace and follows a standard time-temperature curve which is the same for all materials.

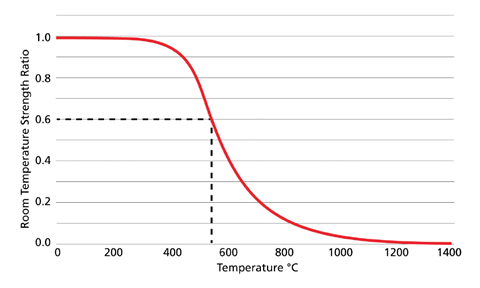

While the strength of steel decreases with temperature, that strength reduction has been quantified through standard fire tests, shown in figure 1 (above). For very large hot-rolled sections, lightly loaded and with some partial protection from concrete floor slabs on the upper flange, inherent fire resistance with no additional protection can be as high as 50 minutes. Where the inherent fire resistance of the steel is less than that necessary to meet the regulations for structural stability for the building, additional precautions must be taken. This usually takes the form of applied fire protection, which insulates the steel from the increasing temperatures, and/or a fire engineered solution.

LEGISLATION AND STANDARDS ON FIRE RESISTANCE

Building Regulations

The obligations placed on those who design and construct buildings to ensure that they are both safe and healthy are contained in the Building Regulations. These are devolved and therefore differ in England, Wales, Northern Ireland and Scotland. The requirements of the regulations are set out in functional terms – that is, they outline what the requirements are but not how they can be achieved.

Requirement B3(1) of the Building Regulations for England states: “The building shall be designed and constructed so that, in the event of a fire, its stability will be maintained for a reasonable period.”

Approved Document B

Each devolved UK government publishes guidance documents on how compliance with the Building Regulations can be achieved. In England, the relevant document for fire is Approved Document B. It contains details of the structural fire resistance requirements to meet designers’ obligations on structural stability. For example, an office building higher than 30m requires 120 minutes fire resistance plus a sprinkler system. An unsprinklered assembly building 18-30m high requires 90 minutes fire resistance.

BS 9999 – Fire safety in the design, management and use of buildings

In recent years, as the result of extensive research into the nature of fire, how it spreads and the risk factors in building fires, BSI has published BS 9999, Code of practice for fire safety in the design, management and use of buildings. The intention behind the development of the document is to provide a more transparent and flexible approach to fire safe design through the use of a structured approach to risk. In many cases, the use of BS 9999 will lead to safer solutions for fire than are possible using the government publications.

One of the most obvious changes in BS 9999 is to structural fire resistance requirements, illustrated in table 1 (below).

| Building description | Approved Document B | BS 9999 without sprinkler system (mins) | BS 9999 with sprinkler system (mins) |

|---|---|---|---|

|

Open-plan office building, two storeys, <1000m2 ground floor area |

30 |

15 |

15 |

|

Open-plan office building, 30-60m in height |

120 + sprinkler system |

90 |

60 |

|

Department store, three storeys |

60 |

45 |

30 |

|

Department store, 11-18m in height |

60 |

75 |

60 |

|

Storage building, medium risk, four storeys |

90 |

90 |

60 |

|

Leisure centre, two storeys |

60 |

30 |

30 |

FIRE RESISTANCE PERIODS

The fire resistance requirements for a building and, therefore its frame, are defined in terms of the fire resistance period and is stated in terms of minutes (15, 30, 45, 60, 75, 90 or 120 minutes).

It is important to note that fire resistance is not the length of time that a structure is likely to survive in a real fire, but a standard measure for comparing the performance of different designs in a consistent manner. In a real fire, once the combustible material or fire load has been consumed, the fire will decay and/or move. In a standard fire test, the temperature rises quickly and increases indefinitely, so conditions are far more severe.

Fire resistance test results are expressed in terms of time to failure against one or more of three criteria for the product/element under consideration. These are:

- Load-bearing capacity – ability to support the applied load and to resist collapse

- Integrity – ability to resist the passage of flames/hot gases

- Insulation – ability to restrict the temperature rise on the unexposed face.

In England the minimum period of fire resistance varies depending on the purpose and height of the building. For open-sided car parks, the minimum period of fire resistance is 15 minutes; for offices over 30m high with sprinklers it is 120 minutes.

FIRE PROTECTION OPTIONS

Unprotected steelwork is usually deemed to have 15 minutes inherent fire resistance. For higher fire resistance periods, fire protection is usually required. Passive fire protection materials insulate steel structures from the effects of high temperatures (this is in contrast to active fire protection systems, such as sprinklers). Passive fire protection materials can be divided into two types: reactive, of which thin-film intumescent coatings are the most common example, and non-reactive, most frequently boards and sprays.

Thin-film intumescent coatings

Thin-film intumescent coatings generally have three components: a primer, a basecoat and a sealer coat. The basecoat is the part that reacts in a fire, and usually comprises the following ingredients:

- A catalyst which decomposes to produce a mineral acid such as phosphoric acid

- A carbonific such as starch which combines with the mineral acid to form a carbonaceous char

- A binder or resin which softens at a predetermined temperature

- A spumific agent which decomposes together with the melting of the binder, to liberate large volumes of non-flammable gases. These gases include carbon dioxide, ammonia and water vapour. The production of these gases causes the carbonaceous char to swell or foam and expand to provide an insulating layer many times the thickness of the original coating.

They are mainly used in buildings where the fire resistance requirements are 30, 60 and 90 minutes, although some products can offer 120 minutes. Coatings can be applied either on or off-site. They can be water or solvent-based, depending on the intended use of the structure. Both can be used to achieve attractive surface finishes. Thin-film intumescents can easily cover complex shapes and post-protection service installation is relatively simple.

Boards

Boards are widely used for structural fire protection in the UK, whether the protection system is in full view or hidden. They can be applied on unpainted steelwork and offer the specifier a clean, boxed appearance. Application is a dry trade and so is less likely to disrupt other trades on-site, and as boards are factory manufactured, thicknesses can be guaranteed.

There are broadly two families of board protection: lightweight and heavyweight. Lightweight boards are typically 150-250kg/m³ and are not usually suitable for decorative finishes. They are cheaper than heavyweight equivalents and typically used where aesthetics are not important. Heavyweight boards are usually 700-950kg/m³ and will generally accept decorative finishes. Both types of board may be used in limited external conditions but the advice of the manufacturer should be sought.

Sprays

Spray protection is extensively used in the US but is less common in the UK. It can be used to cover complex shapes and details. Costs do not rise significantly with increases in thickness, because much of the cost of application is in labour and equipment. Some materials can also be used in external and hydrocarbon fire applications. The downsides are that sprays are not suitable for aesthetic purposes, and as application is a wet trade this may impact on other site operations. A cost allowance may have to be made for prevention of overspray.

Flexible blanket systems

Flexible blanket systems have been developed in response to the need for an easily applied fire-protection material that can be used on complex shapes and details, but where application is a dry trade. There are a limited number of manufacturers of these products.

Concrete encasement

Until the late 1970s, concrete was by far the most common form of fire protection for structural steelwork. However the introduction of lightweight, proprietary systems such as boards, sprays and thin-film intumescent coatings has seen a dramatic reduction in its use. Traditional methods such as blockwork encasement are also used occasionally. Concrete tends to be used where resistance to impact damage, abrasion and weather exposure are important – for example in warehouses, underground car parks or external structures. The principal disadvantages are the higher cost in comparison to lightweight systems, the high space utilisation rate, as large protection thicknesses take up valuable space around columns, and weight.

Detailed guidance on the installation of coatings, boards and spray protection systems is available from the Association for Specialist Fire Protection. Information on the thickness of concrete encasement for specific periods of fire resistance is published by BRE. It can also be found in BS EN 1994-1-2.

Fire safety engineering

Fire safety engineering can be seen as an integrated package of measures designed to achieve the maximum benefit from the available methods of preventing, controlling or limiting the consequences of fire.

The simplest form of structural fire engineering is the use of codes to design individual elements of construction. Techniques for structural fire engineering on assemblies of elements of construction using a simplified method have also been developed, requiring little specialised knowledge on the part of the engineer. These can be used in the design of simplified sub-assembly models and make use of the understanding of the behaviour of composite construction in fire gained from the Cardington fire tests.

Use of these models, which combine the residual strength of steel composite beams with the strength of the slab in fire, allows the designer to leave large numbers of secondary beams unprotected in buildings requiring 30-120 minutes fire resistance, resulting in significant cost savings, although some compensating features such as increased reinforcement in the slab may be required.

How to take this module

UBM’s CPD distance-learning programme is open to anyone seeking to develop their knowledge and skills. Each module also offers members of professional institutions an opportunity to earn between 30 and 90 minutes of credits towards their annual CPD requirement.

This article is accredited by the CPD Certification Service. To earn CPD credits, read the article and then click the link below to complete your details and answer the questions. You will receive your results instantly, and if all the questions are correctly answered, you will be able to download your CPD certificate straight away.

CPD CREDITS: 90 MINUTES

DEADLINE: 16 MARCH 2018

Privacy policy

Information you supply to UBM (UK) Ltd may be used for publication and also to provide you with information about our products or services in the form of direct marketing by email, telephone, fax or post. Information may also be made available to third parties. UBM (UK) Ltd may send updates about Building CPD and other relevant UBM products and services. By providing your email address you consent to being contacted by email by UBM (UK) Ltd or other third parties. If at any time you no longer wish to receive anything from UBM (UK) Ltd or to have your data made available to third parties, contact the Data Protection Coordinator at ubmidpa@ubm.com. View our full privacy policy at www.building.co.uk/cpd

1 Readers' comment