This CPD, sponsored by Glazing Vision, will look at the installation of non-fragile glass in rooflights, including standards, safety testing and assembly specifications, alongside how to maximise acoustic performance and reduce condensation

CPD CREDITS: 60 MINUTES

DEADLINE: 6 MAY 2019

For more information about Assemble Media Group’s CPD distance-learning programme, click here

Introduction

At face value, the role of glazed rooflights or roof windows seems straightforward. They provide natural light and ventilation to a building’s interior, give the occupants a view outside, and can provide a means of access or escape.

The demands placed on building fabric require glazing units to perform similar functions to the building elements in which they are installed. This may relate to the structural loads imposed upon the unit, how well it deals with solar gain or heat loss, or even how much sound is transmitted through the glass.

This CPD will examine what can be determined as non-fragile glass and explore various technical notes, standards, product and safety testing and assembly specifications. It will also address acoustic performance, managing condensation risk and the properties of low-iron glass.

Understanding non-fragility

Glass used in rooflights installed on a roof that is accessible but not designed for regular foot traffic should be specified as “non-fragile”. Depending on the anticipated use of the roof, a non-fragile rooflight is designed to prevent people or objects falling through it in the event of an accident on the roof.

To that end, roof access requirements should be assessed at design stage and specified carefully. The safety of those using the space below the rooflight should also be considered, and the risk posed by falling glass assessed, if a pane were to break.

The non-fragility of a roof glazing product is an important measure, but any such rating should not be taken to imply that the product is safe to walk on.

Most rooflights are designed to be non-fragile and provide a level of non-fragility equivalent to the surrounding roof. Tests for non-fragility are defined in the Advisory Committee for Roof Safety’s (ACR) Red Book (ACR[M]001), which references test guidelines for glass rooflights by the Centre for Window and Cladding Technology (CWCT).

Three technical notes by the CWCT have proved particularly influential, having been developed to establish a clear distinction between “fragile” and “non-fragile” glazing:

- TN66 – Safety and fragility of glazed roofing: guidance on specification

- TN67 – Safety and fragility of glazed roofing: testing and assessment

- TN92 – Simplified method for assessing glazing in class 2 roofs.

TN66 categorises glazed roofing using four classes:

- Class 0: roofs designed for unrestricted access by building occupants.

- Class 1: roofs walked on for occasional cleaning/ maintenance activities, which need to support the weight of people and their equipment, and which could be subject to impact from a person, and/or any object carried, falling onto its surface.

- Class 2: roofs where people are not intended to walk on the glass, but which are required to be non-fragile to protect maintenance personnel when they are walking adjacent to the glass roof and could trip or fall on to its surface, or working on the glass roof and could fall onto its surface from crawler boards or other access equipment.

- Class 3: fragile roofs.

Hard- and soft-body impact testing under TN67

TN66’s classifications lead to testing under TN67, often with the result that glazing falls into class 2. TN92 therefore gives alternative routes to compliance for class 2 roof glazing.

TN67 includes two types of drop test:

- The “hard body” test, where a steel ball with a mass of 4.11kg is dropped through a height of 1,200mm to give an impact energy of 48J, representing an object being dropped onto the rooflight, or a person stumbling onto the rooflight while carrying an object.

- The “soft body” test, where a 45kg sandbag is dropped from a minimum height of 1,200mm, giving an impact energy of at least 530J, intended to simulate a person falling on top of the rooflight.

Any unbroken panes of glass are then broken and sandbags totalling 180kg placed on the glass to represent an injured person, alongside somebody helping them. The broken glass has to support the 180kg load for up to half an hour. The procedure is repeated on two more samples to check the consistency of results.

In all cases, nothing must pass through the glass. Any fragments of glass that fall from the tested glass are measured and weighed to assess the risk to people below. Results will apply to the tested pane size and specification/glass type, frame support system and method of glass retention in the frame. These factors should be kept in mind when looking to specify a bespoke rooflight product.

Roof assembly testing under ACR[M]001

The previous examples are product tests, while ACR[M]001 details a roof assembly test, of which a rooflight can be a part. The ACR non-fragility test defines three classes of roof assembly: A, B and C.

Only a product specifically designed to be used structurally can be considered a walk-on rooflight. The recommendation from the National Association of Rooflight Manufacturers (NARM) is to qualify their use with a phrase such as: “must be designed to floor loadings”.

Words such as “walkable” and “mansafe” are undefined, nor are they recognised in relation to glazing and, in some cases, are related to other proprietary roof access equipment. Walk-on rooflights are outside the scope of TN66 and TN67.

Specifying the correct glass for foot traffic

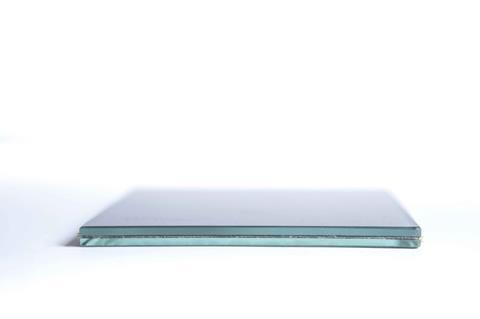

Glass is the only material appropriate for a rooflight product designed to take foot traffic. The outer pane should be toughened, heat soak-tested and laminated, usually with three glass layers – and possibly an additional sacrificial pane – for a total thickness of 25mm to 49mm (or more in extreme situations).

Glazed flooring is heavier than a high-specification rooflight and the roof structure has to be designed to take the loads imposed by products of such weight.

Other contributing loads to consider

It is not only loads imposed by people that need to be taken into account – resisting the elements is just as important. A roof is subject to wind loading all year round. The test method in BS EN 12211 describes how to undertake and assess pressure testing, wind resistance and frame deflection. Snow is more seasonal but can linger and increase over an extended period of time. The ability of roof glazing to withstand snow loading is tested in terms of long-duration loading, and any deflection in the centre of the glass measured accordingly.

Site location is a significant factor in determining the wind and snow loads to which roof glazing is exposed and should be considered accordingly.

| Application | Domestic | Commercial | Heavy-duty |

|---|---|---|---|

|

Uniformly distributed load (UDL) (kN/m2): |

Up to 1.5 |

Up to 4.0 |

Up to 5.0 |

|

Concentrated load (kN/m2): |

Up to 2.0 |

Up to 3.6 |

Up to 4.5 |

Acoustic performance of glass

The acoustic performance of rooflights is impacted by whether the rooflights are double- or triple-glazed, the size of gap between panes and the thickness of the panes. Glass – whether annealed, toughened or heat-strengthened – follows the mass law of sound transmission, where doubling the thickness of a pane (and therefore its weight) reduces sound transmission by 4dB to 6dB.

Laminated glass offers a greater benefit from the use of a thicker PVB interlayer, or standard EVA interlayer, which is the soft plastic material changing the composite product’s response to sound transmission. Specific acoustic interlayers are available to improve performance further. Double- and triple-glazed products use glass panes of different thicknesses to reduce “sympathetic resonances” – the reduction of sound of equal frequencies. A double-glazed unit might be expected to achieve a sound reduction of about 32dB; a triple-glazed unit may achieve a reduction of 40dB.

Greater benefit would only be seen with significantly increased distance between the glass panes – up to 200mm for the best, albeit impractical, effect. Scenarios in which this would be desirable lend themselves to the specification and installation of secondary glazing. Although not directly related to the glass, the acoustic performance of a rooflight unit as a whole depends on the quality of its installation and airtightness. Air leakage and resulting sound transmission around the whole unit can be addressed by lining the reveals with a sound-absorbing material.

Reducing condensation risk using heated glass

Condensation risk leads to some people choosing heated glass. Any area of glazing suffers greater heat loss than the building fabric around it, so its surface temperature will be colder. When warm air containing moisture vapour comes into contact with that colder surface, the air temperature drops and excess moisture is deposited as condensation.

For rooflights that cannot achieve U-values low enough, and/or applications where the moisture load/humidity is particularly high, heated glass raises the surface temperature of the rooflight, reducing the potential volume of condensation occurring on it.

The best way to eliminate condensation risk is thermally efficient building fabric and controlled ventilation, rather than consuming more energy through additional heating. Changing the level of risk in one place may shift the likelihood of condensation occurring to the next-coldest surface, so heated glass should be specified with care, and for the right reasons – for example, in high-humidity environments such as swimming pools.

Anti-slip treatments

Other applications for heated glass include evaporating rainwater or dew, and melting ice and snow. However, walk-on rooflights are slippery when wet and anti-slip finishes provide an antidote to the inherent risks. Homeowners might be unlikely to access their roof in adverse conditions, but on commercial and other non-domestic buildings, access to roofs can be required any day of the year.

Sandblasting the surface of rooflight glass can increase slip resistance, while adding obscurity and creating light diffusion. More commonly, ceramic frit paint is used. The frit is screen printed or digitally printed onto annealed glass before tempering to achieve the desired performance. Fired permanently into the surface of the glass, the frit provides slip resistance. Textured glasses offering slip resistance are also available.

Slip resistance is measured by pendulum test values (PTV), with a higher PTV meaning better slip resistance. A surface with a PTV of up to 24 has a high risk of slipping, while 25 to 35 is a moderate risk and 36 or more is a low risk. Sandblasted glass and fritted glass generally achieve PTVs of 50 and 60 respectively, so are both considered low risk. Wet and dry tests are carried out, and lower figures are unsurprisingly achieved in wet conditions.

Ceramic frit and screen-printing techniques can also be used for decorative effect, especially in conjunction with enamelled glass. Ceramic paint is applied to the glass before toughening. The toughening process fires the paint into the surface of the glass.

Glass is not always transparent

Decorative uses of glass, and other situations where clarity is particularly desirable, lend themselves to the use of low-iron glass. The silica used in the initial glass production is selected for its low iron content, removing the natural green/blue colouring that occurs otherwise.

Other visual effects can be achieved using smart glass, also known as switchable glass, but for entirely different reasons. Electrochromic glass features an interlayer that responds to a small electrical current passing through it, changing the glass from translucent to opaque. Reversing the electric potential makes the glass clear again. The level of current applied can alter the depth of colouration. This technology can be used for privacy purposes or as a means of solar control and shading.

How to take this module

Assemble Media Group’s CPD distance-learning programme is open to anyone seeking to develop their knowledge and skills. Each module also offers members of professional institutions an opportunity to earn between 30 and 90 minutes of credits towards their annual CPD requirement.

This article is accredited by the CPD Certification Service. To earn CPD credits, read the article and then click the link below to complete your details and answer the questions. You will receive your results instantly, and if all the questions are correctly answered, you will be able to download your CPD certificate straight away.

CPD CREDITS: 60 MINUTES

DEADLINE: 6 MAY 2019

Privacy policy

Information you supply to Assemble Media Group Limited may be used for publication and also to provide you with information about our products or services in the form of direct marketing by email, telephone, fax or post. Information may also be made available to third parties. Assemble Media Group Limited may send updates about Building CPD and other relevant Assemble Media Group Limited products and services. By providing your email address you consent to being contact by email, telephone, fax or post by Assemble Media Group Limited or other third parties. If at any time you no longer wish to receive anything from Assemble Media Group Limited or to have your data made available to third parties, contact the Data Protection Coordinator at building@building.co.uk. View our full privacy policy here

No comments yet