This CPD, sponsored by Keylite, will outline specification issues, as well as guidance relating to installation, technical performance including energy savings, security and ventilation, and safety.

CPD CREDITS: 60 MINUTES

DEADLINE: 13 JULY 2018

For more information about Assemble Media Group’s CPD distance-learning programme, click here

INTRODUCTION

Roof windows can benefit a building by boosting natural light coming into the structure, while increasing its energy efficiency and offering aesthetic benefits which marry up with architectural design and performance best practice.

Other factors can include:

- Health & Safety

- Design Solutions

- Smart Automation

This CPD will outline specification issues, as well as guidance relating to installation, technical performance including energy savings, security and ventilation, and safety.

SPECIFICATION

ISO 9001 is the international standard that specifies requirements for a quality management system. Additionally, certifications such as BBA approval and CE registering are marks worth looking out for when specifying products.

Most manufacturers will provide CAD details for architects and specifiers. However since some of the industry is moving over to BIM, manufacturers now provide BIM models that can be used when designing in programmes such as Revit, as well as being available in Industry Foundation Class (IFC) format – IFC being the international standard for building information modelling used for sharing and exchanging construction and facility management data across different software applications.

When specifying roof windows, it is important to consider advances in design and the latest regulations and how these can impact upon the performance of the building fabric.

The thermal performance of roof windows should be a key consideration in order to ensure the overall performance of the building is not compromised for the end user.

Research has found that a large majority of roof windows are installed in the UK and Ireland without the manufacturer’s specified thermal collar, reducing the thermal performance. Studies carried out by the Zero Carbon Hub indicate that fabric is often being improperly installed, compromising crucial elements of the thermal design. This leads to an increased focus on installation practices for insulation, detailing and airtightness.

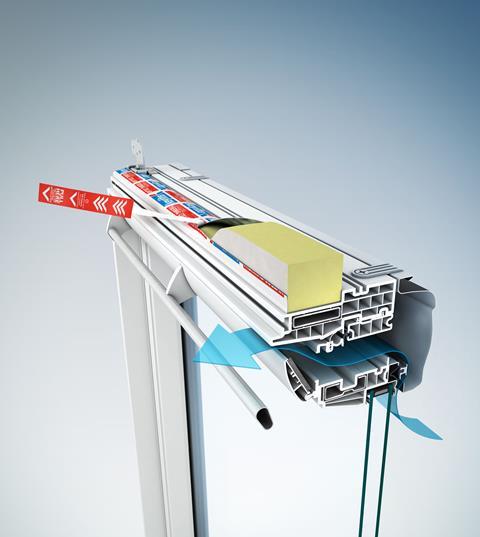

Every manufacturer recommends the structural opening size for a roof window is oversized for ease of installation, usually by around 20mm. This leaves a void around the edge of the frame which is supposed to be insulated with an item called a thermal collar. However, such specified thermal collars are often never bought or installed, meaning that heat escapes around the perimeter of the frame, causing thermal bridging.

The main reason for omitting thermal collars is cost, since they are usually sold as an additional product, costing around £30-£40 per window, however human error can also play a part, with collars often being mistaken for foam packaging resulting in them being thrown away.

THERMAL BRIDGING

A thermal bridge, also called a ‘cold bridge’, is an area of a building construction which has a significantly higher heat transfer than the surrounding materials. The heat loss associated with these thermal bridges is expressed as a linear thermal transmittance (Ψ-value) – pronounced as ‘psi-value’.

As dwellings become better insulated, the importance of thermal bridging has increased. In very well insulated dwellings, the effect that thermal bridging can have on its overall thermal performance can be significant. Recent research has shown that thermal bridging can be responsible for up to 30% of a dwelling’s heat loss.

Standard Assessment Procedure (SAP) calculations – which are required under Building Regulations – now include assessments of thermal bridges in a building’s performance, including junctions between a roof window and a roof.

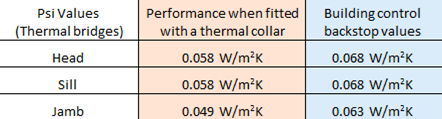

Psi-values are considered independently to a ‘u-value’, which measures a material’s effectiveness as an insulator. Within a roof window, there are three values to consider:

- the head

- the sill

- the jambs

As shown on the table (fig 1), the figures in red demonstrate how specifying a window with an expanding thermal collar improves on the backstop values – effectively the minimum requirements under Building Regulations – in blue, which are set by building control.

INSULATION

If a roof window is installed but not insulated in the roof opening its thermal performance within the opening is clearly going to be compromised. Studies have found that a window with an expanding thermal collar performed as specified with a u-value of 1.3 W/m2K in the roof opening, while another window with, on paper at least, the same specified performance but without the thermal collar experienced a 30% loss in performance, achieving just 1.7 W/m2K.

Improper insulation results in cold bridging, leading to condensation, and eventually mould growth. With the development of better insulated houses, pressure is put on the junctions within the fabric where thermal bridging happens, such as at the corners of windows.

The British Standards Institute has recognised that surface condensation and mould growth are unlikely to occur on the underside of the ceiling provided that:

a) no gaps have been left in the insulation covering the ceiling

b) thermal bridging is minimised, particularly at the junction of the roof with the external walls and around roof windows.

When junctions between a roof window and a roof are properly insulated, psi values are improved as well as air tightness and cold bridging is reduced, along with it the risk of condensation.

Where a roof window does not feature a thermal collar, the surface temperature of the frame is lowered below the dew point, which leads to condensation. On a window installed with a thermal collar, the surface temperature of the frame stays above the dew point, eliminating the risk of condensation forming on the timber.

Research suggests that failing to install a thermal collar results in an additional cost of between £60 and £130 per product over its useful life, suggesting the whole life cost of window without a collar is at least 60% more expensive than a window which features a collar.

Looking at this on a national scale puts such an energy saving into context; there are around 650,000 roof windows installed in the UK annually which feature no thermal collar, equivalent to 12.07 GWh of energy lost, heating 3,500 semi-detached homes, or losing the same amount of energy generated by 11 hectares of photovoltaic panels – an area equivalent to approximately 16 football pitches – at a cost of £22m.

GLAZING

Energy efficiency can be improved through a choice of glazing option. There are various types which can be fitted within roof windows that change both the thermal performance and the visual aesthetics of the units. Triple glazing can improve the overall u-value of a window unit by 33% whilst safety glass can also be utilised when windows are at height. Self-cleaning glass solves the issue of access to windows fitted at height.

To enhance a roof window’s thermal performance and reduce cold bridging and condensation it is recommended to specify roof windows with a ‘warm edge glazing’ feature, where a composite space is used between the glazing panes to reduce heat transfer and the risk of condensation.

SAFETY

Falling from heights, particularly from roofs, is a preventable cause of injury at work, particularly in construction, and the installation of heavy roof windows presents identifiable risks. To improve safety, a window should be specified that has features to enable the installer to fit from inside the roof and in some cases without removing the sash.

Generally, fitting brackets will come separate to the window and have to be fitted to the frame before installation. This makes the units bigger than the structural opening and more difficult to install, often being done from outside on the roof. Minor injuries can arise when installing the sash back into the frame but a spring loaded sash hinge finger is a feature that allows the heavy sash to be installed back into the frame in one smooth, effortless motion.

In order for a roof window to be considered as a means of escape it should have an unobstructed opening area of at least 0.33m², and the opening must be a minimum of 450mm high and 450mm wide. The bottom of the roof window frame should be installed between 600 – 1,100mm off of the finished floor level for ease of egress by the occupants and to enable access for emergency services.

Finally the bottom of the frame must not be more than 1,700mm from the eaves of the roof to ensure ease of escape off the roof.

SECURITY

A secure window under part Q guidelines in the Building Regulations should be able to resist criminal attack or incorporate construction features that are proven to reduce crime.

Windows should be made to a design that has been verifiably tested to meet the security requirements of British Standards including PAS 24: 2012.

There are another three standards that can be met to be Approved Document Q (Security in Dwellings) compliant. These can include a metal locking bolt at the top and bottom of the frame; non-reverse screws; a bottom handle, and laminated glass which can resist manual attack.

VENTILATION

Ventilation requirements are covered under building regulations technical booklet F.

For the purposes of this CPD, we will focus on two types of construction relating to part F and how roof windows can enable them to meet compliance:

- New dwellings (Section 5)

- Work on existing dwellings (Section 7)

NEW DWELLINGS

Ventilation for new dwellings is measured differently from that in existing dwellings. It is done via a Whole Dwelling Ventilation (WDV) rate, measured in litre/second which is determined by the number of bedrooms in a dwelling.

For a three-bedroom house, the WDV rate is 21 l/s. Two of the most commonly-used windows, at 780mm wide, will satisfy the ventilation requirement for the dwelling since each window provides just over 11 l/s. This prevents the requirement for any mechanical or alternative ventilation.

It is important to check a manufacturers’ ventilation rates when specifying as these figures may not be will same for all manufacturers.

EXISTING DWELLINGS

Existing dwellings are measured with an equivalent area for trickle ventilation in mm² per room instead of a whole dwelling rate calculated via l/s.

Per habitable room 500mm² equivalent trickle ventilation is required. Taking the most common roof window size of 780mm wide, two of these windows will satisfy the requirements for each room since each window provides just over 3,000mm² of equivalent trickle ventilation. The area for not inhabited rooms, bathrooms, kitchens and so on is 2,500mm².

Another feature of roof windows is their ability to be used for smoke ventilation in the event of a fire. The most common sized windows for smoke ventilation offer 1m2 ventilation area or 1,500mm².

AESTHETICS

A recessed fit enables the roof window to sit lower in the roof covering, therefore enhancing the overall appearance in the roof. It also helps to improve the thermal performance of the roof window.

The coating on white-painted roof windows protects the wood against dirt and moisture, while extruded PVC offers a maintenance-free, moisture resistant option that can be easily wiped clean and is 100% recyclable.

![REW_BATHROOM_ESTABLISHING_G_FROSTED_[F01]](https://d3sux4fmh2nu8u.cloudfront.net/Pictures/480xany/9/8/2/1851982_rew_bathroom_establishing_g_frosted_f01_458443.jpg)

LIGHT

Roof windows offer architects and designers flexible solutions in bringing daylight into most types of interior spaces, offering up to twice the light transmission of vertical windows. It is important to consider the position of roof windows in order to maximise how successful they prove to be within design.

Rooms with vaulted ceilings are dramatically enhanced by the addition of overhead roof windows. Multiple combinations of windows can be used to maximise light, whilst electric operation can be utilised for ease of use, especially in out of reach areas.

Roof lanterns are an attractive option for a flat roof when wanting to maximise natural light. Modern aluminium glazing bars are slimmer in profile, ensuring maximum penetration of light.

Other flat roof systems include installing roof windows, either singly or in an atrium style, facilitated by a proprietary upstand. Another solution which can be used on a flat roof is a flat roof dome, thermoformed with polycarbonate using a triple skin construction. Polycarbonate is virtually unbreakable, with an impact strength 250 times greater than glass.

Sun tunnels can be used to transport natural daylight through roofing voids into spaces where conventional pitched or flat roof windows cannot be used. There are options for a rigid aluminium reflective tube or a flexible foil tube.

It is essential that all roof windows are installed with a flashing kit. Manufacturers’ specification/technical teams should be consulted to ensure the flashing specified is suitable for the pitch/type of roofing finish on the project.

SMART AUTOMATION

Electric automation can be used in conjunction with roof windows for ease of operation.

Roof windows can be supplied with wall mounted switches or remote control operation that allow multiple windows to be operated together. Rain sensors provide protection by automatically closing windows in the event of unexpected showers.

Where smoke ventilation is required, roof windows can be specified with an automated bespoke ventilation control, designed to open a roof window automatically in the event of a fire. Optional wind deflector can be supplied where BS EN1201-2 compliancy is required. This regulation may not be compulsory on every project, so specifiers should consult local building control regarding smoke ventilation requirements.

How to take this module

Assemble Media Group’s CPD distance-learning programme is open to anyone seeking to develop their knowledge and skills. Each module also offers members of professional institutions an opportunity to earn between 30 and 90 minutes of credits towards their annual CPD requirement.

This article is accredited by the CPD Certification Service. To earn CPD credits, read the article and then click the link below to complete your details and answer the questions. You will receive your results instantly, and if all the questions are correctly answered, you will be able to download your CPD certificate straight away.

CPD CREDITS: 60 MINUTES

DEADLINE: 29 JUNE 2018

Privacy policy

Information you supply to Assemble Media Group Limited may be used for publication and also to provide you with information about our products or services in the form of direct marketing by email, telephone, fax or post. Information may also be made available to third parties. Assemble Media Group Limited may send updates about Building CPD and other relevant Assemble Media Group Limited products and services. By providing your email address you consent to being contacted by email by Assemble Media Group Limited or other third parties. If at any time you no longer wish to receive anything from Assemble Media Group Limited or to have your data made available to third parties, contact the Data Protection Coordinator at building@building.co.uk. View our full privacy policy at www.building.co.uk/cpd

No comments yet