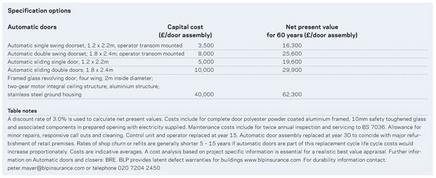

Doors for retail premises not only have to look good but meet a host of functional requirements. Peter Mayer of Building LifePlans runs through the issues and life-cycle costs

Guidance on the specification, design, installation, operation and maintenance of automatic doors for safety, is provided by BS 7036, which comprises five standards.

Automatic doors are operated by some form of presence-sensing device. Positioning of the sensors is critical for effective operation. Operator devices which move the door are typically electrical motor driven, pneumatic or hydraulic. Control units may be required. Where power supply fails doors operate manually. Control systems have lifetimes of between 10 and 20 years.

Door types

Swing door Just like a normal hinged door but automatically operated. BS 7036–3 applies. Commonly provided as a low energy swing door (BS 7036–4) powered so that users are unlikely to be harmed if struck by the door.

Sliding or folding door The door leaf of sliding doors may be straight or curved, these slide horizontally across the opening. See BS 7036–2 for avoidance of body traps.

Balanced door For use where space is restricted. The door opens with a combined sliding and swing action. See BS 7036–3.

Revolving door BS 7036–5 gives guidance on maximum revolving speed. Additional safety devices are required for revolving doors with an internal diameter greater than 3m.

Door construction

Automatic doors for retail use are constructed from glass or metal-framed glass. Typically aluminium, stainless steel or decorated galvanised steel is used. Timber-framed glass doors are also available.

Aluminium may be mill finished. Anodising is to BS 3987, minimum 25 microns thick, for an expected service life of 30-plus years.

Decorative coatings for both aluminium and steel include PVC plastisol (10-30 years), polyvinylidene fluoride PVF2 minimum 25 microns thick (10-20 years), polyester (five-10 years), polyurethane (10–15 years). Life depends on exposure to coastal, polluted or industrial environments, aspect and orientation, as well as coating thickness.

In a retail environment the door leaf life expectancy is more likely to be related to appearance than physical functionality.

Safety glass is used in framed or frameless doors. Typically toughened glass to BS EN 12150 or laminated safety glass to BS EN ISO 12543. BS 6206 for impact performance of safety glass describes three categories: Class A is the most resistant to impact. Insulating glass units to BS EN 1279 may be used for improved thermal performance.

Functional requirements

Safety BS 7036 considers issues such as signage, finger trapping and tripping risk, inclusion of protective barriers, proper operation of safety devices, activation, opening forces and opening times as well as the condition of operating devices and the door. A full hazard analysis and risk assessment should be carried out to guidance from HSE Code of Practice L21 and BS 5304 for safe use of machinery.

Accessibility Disability Discrimination Act applies. Automatic doors and shop entrances may require additional safety measures for people with disabilities or the elderly.

For further guidance go to: Centre for Accessible Environments and BS 8300 for the design of buildings and their approaches for disabled people.

Emergency escape This can be achieved by break-out facility which may be manual or integral to a fire alarm system.

Weathertightness and physical properties of doors are covered in BS EN 14351–1:2006. BS 6375 is still applicable as a guide to specification for weathertightness.

Security Locking systems, ironmongery and hinges should be specified for the expected use and resistance to forced entry.

Operation and maintenance

Automatic doors come under the Provision and Use of Work Equipment Regulations 1998. BS 7936–1 gives guidance: regular maintenance and annual inspection.

Specifier 23 May 2008

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

- 13

Currently

reading

Currently

reading

Doorstep challenge

No comments yet