The whole-life costs of textile floor coverings can be distinctly pricey for commercial and domestic buildings. Peter Mayer of Building LifePlans reviews the options

The whole-life costs of sheet or broadloom textile floor coverings can be high as they often need replacing and can cost a lot to clean. Factors to consider include: making sure the carpet system suits the substrate, the expected use and environment, maintenance and cleaning.

The classification of pile carpets is covered by BS EN 1307:2005. There are four domestic use classes, ranging from moderate/light to heavy, and three commercial use classes: moderate, general and heavy. Use classes are categorised by the carpet’s resistance to wear and change in appearance. EN 1307 also includes a luxury classification.

BS EN 13297 classifies needled pile floor coverings in a similar fashion, with three domestic and two commercial use classes.

Extra performance characteristics may be determined for demanding environments such as those with caster chairs, as defined by the test standard BS EN 985, suitability for underfloor heating to ISO 6356, dimensional stability in intermittent humid conditions to ISO 2551 and use on stairs to EN 1963.

High-use locations such as airports may require tougher specifications.

Installation guidance can be found in the code of practice BS 5325 and the Contract Flooring Association Manual, as well as manufacturers’ guidance.

Underlays are important to improve comfort, insulation and the expected life of the carpet. They may be fibrous, foam (rubber or polyurethane), rubber crumb or a combination of fibre and non-fibrous materials.

BS EN 14499 defines minimum performance standards and BS 5808 defines a minimum requirement for compression.

Cleaning is critical to long-term performance. A British Standard Product Assessment Specification (PAS 86) for carpet cleaning is being developed. In the meantime, cleaning should be based on manufacturers’ guidance and the advice of specialist carpet cleaners.

Performance of textile floor coverings can be enhanced by the use of entrance mats, multicoloured or patterned carpets to conceal dirt and positioning seams away from areas of high wear.

Sheet textile floor coverings

Cost and performance is not just related to use class but pile fibre, construction, colour, texture and design.

Natural fibres The quality of 100% wool carpets is related to the length of pile, density of yarn and tufts. These tend to be used in the luxury and domestic markets.

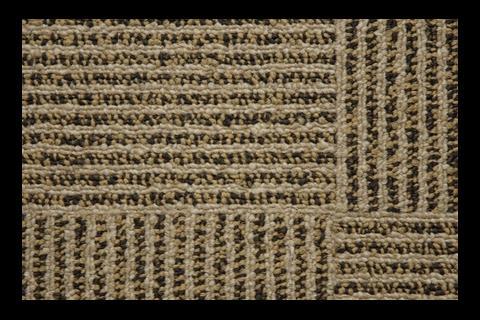

Other natural fibres are often specified for environmental reasons. Common materials include coir (coconut fibre), seagrass, jute and sisal.

There are no BS specifications for these woven materials, apart from coir matting to which BS ISO 11861 refers. Performance data and use class descriptions may be provided by makers.

Sisal is the most hard-wearing and can be used for commercial applications. Coir is also hard-wearing but has a coarse finish so may not be desirable in commercial or public areas.

Seagrass and jute are typically used for domestic environments. Avoid seagrass on stairs as it contains natural oils.

Manmade fibres Nylon or polyamide fibres can be produced in the full range of use classes with excellent wear performance. Nylon 6.6 is the best-performing type. Textiles can be engineered to provide enhanced performance such as easier cleaning or improved wear resistance. These claims should be confirmed from evidence in performance and test data.

Acrylic, polyester and polypropylene fibres are also used but do not give the same all-round performance as nylon.

Wool-nylon mix Typically 80% wool and 20% nylon carpets offer a compromise between the luxury of wool and the wear characteristics of nylon at a cost between the two. An 80-20 carpet will have better abrasive resistance than a 100% wool one and will perform better in very high traffic areas.

Postscript

BLP provides latent defect warranties for buildings www.blpinsurance.com. For durability information contact: peter.mayer@blpinsurance.com or telephone 020-7204 2450

Specifier 4 May 2007

This week: Flooring

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

- 13

- 14

Currently

reading

Currently

reading

What it costs: Textile floor coverings

No comments yet