Three more high-performing options that help reduce heat loss from buildings

When it comes to specifying windows, the embodied impact has a small overall bearing on the building. The main consideration for specifiers is heat loss through them. Here we take a look at three high-performing alternatives.

1 Timber: U-value 0.9W/m2K

The Ecocontract range from the Green Building Store is aimed specifically at larger residential and commercial projects in which developers are trying to meet the criteria for BREEAM and the Code for Sustainable Homes. The windows are manufactured entirely from laminated Forest Stewardship Council European redwood, oak or mixed Accoya – a timber product made using a non-toxic wood acetylization process.

But it’s the U-values that we’re most interested in. The double-glazed, 24mm argon-filled unit achieves an overall U-value of 1.4W/m2k, with a light transmission of 79%. While the triple-glazed, 44mm argon-filled unit achieves a U-value of 0.9 W/m2k with the aid of a warm-edge spacer, and has a light transmittance of 72%. Under the Code for Sustainable Homes the windows meet level one for energy and three for materials. It also has an A rating under the Green Guide to Specification.

2 PVCu: U-value 0.8W/m2K

High performance windows have long been the preserve of northern European countries, often with long lead times and a price premium. LB Plastics is aiming to address this with a specially developed PVCu system capable of achieving U-values well below 1W/m2K.

The Sheerframe HED (homogeneous energy dynamics) system is aimed directly at the mainstream housebuilding sector trying to meet levels five and six of the Code for Sustainable Homes. The secret to its performance is the window system’s reinforcement – Thermlock. This patented reinforcement made out of thermoplastic offers, the company claims, the structural strength of conventional steel and aluminium – its deflection strength is 35% higher than aluminium – but with significantly reduced thermal conductivity. In addition, several separated structural chambers within the profiles further improve thermal efficiency.

Together, these characteristics eliminate the need to use costly combinations of glass and gas as in a standard Sheerframe window, says the company. So while the reinforced PVCu windows have the strength to meet BS 7950 and Secured by Design requirements, they can also achieve U-values of 0.8W/m2K.

3 Aluminium-clad timber: U-value 0.7W/m2K

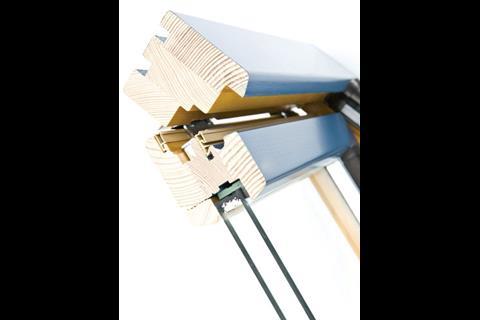

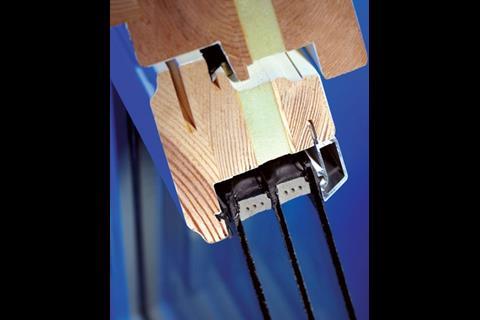

Norwegian window manufacturer NorDan’s NTech range of windows achieves a U-value of 1.2W/m2K and has a 92mm insulated frame and double-glazed, sealed units with low emissivity coated glass that cuts energy loss by 20%, the company claims. The Ntech Passive goes one step further with a U-value of just 0.7W/m2K.

This window has a 105mm insulated frame and triple-glazed sealed units with low emissivity coated glass, which cuts energy loss by 54%.

To improve lifespan and address maintenance costs, NorDan also offers optional aluminium cladding, where 2mm-thick aluminium extrusions are clipped to the outside of the window frame. NorDan has carried out extensive lifecycle assessments of its windows and concludes that there are significant savings in both maintenance and energy losses over their lifetime, in real cost terms. The substantial reductions in energy losses, it claims, add to this figure. If energy inflation of 6.2% per year is taken into account, these differences become substantial, far outweighing any differential in capital costs.

Postscript

This article appeared in the 5 September 2008 edition of Building under the headline: The alternatives: efficient windows

No comments yet