The Scottish Parliament uses textbook design methods to cut carbon emissions, but in practice it is still guzzling energy. So, Jason Palmer asks, what’s gone wrong?

- Estimated at £10 million and built for £345 million, the Scottish Parliament was years late and it doesn’t work properly, so what went wrong with its low energy solutions?

- Graphical data shows results for energy use and results are worse than air conditioned offices.

- Problems encountered include bad lighting, rushed commissioning and poor estimates of ‘energy efficient’ cooling and water heating strategies.

- The good points; landscaping, cycle parking and recycling bins; and the politicians seem to like it…

By rights, new government buildings should set an example for others to follow. They should demonstrate exemplary health and safety on site. They should be fully accessible to all members of society. Above all, they should do everything possible to address sustainability issues and climate change.

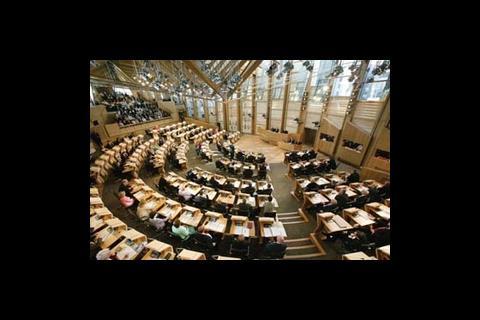

Scotland’s Gaudi-esque parliament building, Holyrood, ought to have been the perfect opportunity to embody these high ideals. Instead, it has caused ongoing controversy as a result of spiralling costs (from £10millon when it was first properly mooted in 1997, to a staggering £345million by completion) and long delays.

But the media storm has largely failed to pick up on what is arguably the biggest disappointment of this building. Here was a project that had every reason to achieve impressive green credentials. The briefing for the project put environmental concerns right at the heart of the design, envisaging clear targets for low energy design. The stated aims were an Excellent rating under BREEAM, and the “good practice” benchmark from Econ 19. But now that Holyrood is up and running it is becoming clear that its energy use and CO2 emissions output falls far short of these ambitions.

The failing is not for the want of good intentions on the part of the services designers. UK architect and services engineer RMJM persuaded its partner, architect Enric Miralles from Catalonia, that low energy systems could deliver the requisite standards of comfort. And, although Miralles insisted that the building services should not be intrusive and that the m&e remain invisible to visitors, designs went forward on this basis – with a preference for low energy solutions.

There were several strands to the engineers’ strategy to reduce energy use. Natural ventilation is used in most areas of the building, even where the depth of plan would normally rule out “natvent”. The Members of the Scottish Parliament wing and other offices are entirely naturally ventilated, and this system extends to most of the public foyer in the debating chamber building and the garden lobby. Where occupants need more fresh air than can be provided by natural ventilation alone, low velocity displacement ventilation is used.

Where cooling is required, it is provided as comfort cooling (rather than full air conditioning), partly through the use of boreholes. These already existed on site, having provided the water for beer brewed by its previous owner, Scottish and Newcastle. Two new boreholes were drilled, providing 10,000 litres/h of water at 10-11°C. Most of the chilled water circuits run at more than the conventional 5°C and 11°C, with the result that well water is used for all but the most extreme areas, such as IT rooms and kitchens.

As a failsafe precaution, there are also chillers large enough to cope with the whole cooling load – RMJM couldn’t risk the debating chamber getting too hot when the MSPs are sitting. Once the water has passed through a heat exchanger, it is also used as greywater for flushing the building’s many WCs.

Insulation was another prime concern, and the engineers aimed to achieve U-values of 0.225-0.25 W/m2K for walls and 1.4 W/m2K for windows. To reduce energy use, an array of solar collectors was installed to generate domestic hot water on sunny days. These take the pressure off gas-fired calorifiers, saving gas and reducing CO2. There are 40 m2 of solar water heating panels on the roof of the Canongate building – the only spot not visible from Holyrood Park, and consequently the only place planners would countenance such technology.

A combined heat and power boiler is also used to generate electricity on site. Waste heat created as a byproduct delivers 150 kW of the Parliament’s full 2.4 MW heating load.

So far, so good. And yet meter readings from the BMS two years after handover show that both gas and electricity consumption were higher than the good practice benchmarks for an air conditioned “prestige” office – the level of Econ 19 that the project was aiming to achieve (see Figure 1, opposite). Gas consumption was 16% higher per m2 in 2005, while electricity was 20% higher.

A bad light

Part of the blame for this outcome lies with the lighting, for which different strategies are used in different areas. In the debating chamber and committee rooms, it seems that camera-friendly lighting took precedence over energy efficiency. Metal halide lights are used – about two spots per MSP, each one precisely positioned using lasers to make sure no shadows fall on members’ faces during TV interviews.

A lighting control system was installed using timers and movement sensors for most areas, but the debating chamber and committee rooms were excluded because it was felt that timer controls were inappropriate, so security staff are meant to switch off lights manually. However, there are clearly some problems with lighting control – when I visited, lights were on in the empty debating chamber and in committee rooms.

Ineffective or rushed commissioning is all too familiar on large building projects that run late, and it is possible that mechanically ventilated parts of the complex are not currently making the most of variable speed pumps and fans. There is little evidence available, but it may be that they are not being wound down during periods of low occupancy, for example over the summer. This would push up consumption of both electricity (for fans and pumps) and gas (for winter heating).

The benefits of using well water for cooling and solar thermal panels to provide some hot water might seem obvious. But, in practice, these appear to be very small compared with total energy consumption. RMJM assumed during design that the thermal panels would meet 60% of the domestic water load for Queensbury House and the Canongate building, equivalent to savings of 24,000 kWh/year, or less than 1% of annual gas consumption for the parliament. In fact, the amount is insufficient even to appear as a gas saving in Figure 1.

When you look at energy consumption over the year, it is surprising that there is no change in electricity consumption during the summer recess. Although the Parliament remains open for visitors, one might expect significant savings from lower ventilation rates and reduced lighting in the debating chamber, committee rooms and offices. One might also think that electricity use for small power – particularly IT and task lights in the MSP offices – would be lower. However, sub-meter records broken down by final use indicate no such savings. Apparently there is significant potential for trimming power use in the summer, and also in other periods when MSPs aren’t sitting, such as Christmas and weekends.

Sustainability

When it comes to the building methods, the vast quantity of concrete used – despite the fact that aggregate and sand were sourced locally – means that embodied energy is high. CO2 emissions from the construction are even worse because making concrete emits about 0.87 tonnes of CO2 per tonne poured.

On a more positive note, this is to be weighed against durability – this building will not degrade in a few decades in the way some lightweight buildings will. And the thermal capacity and exposed soffits will help to keep internal temperatures stable even if Edinburgh’s peak temperatures rise as a result of climate change.

In some areas, the designers showed a preference for local materials. The debating chamber has Scottish oak, for example, and 8,500 m2 of Kemnay granite from Aberdeenshire for cladding. But anti-competitive measures in European tendering made it difficult for the architects to use only Scottish materials. Nevertheless, questions also remain about whether it was really necessary to import South African granite for some of the cladding on the MSP wing.

Turning to the landscaping, there is plenty of good work. Rare plants, lichens and local grasses were included to promote biodiversity and more than 40 cycle parking spaces exist alongside the 65 car parking slots for staff. Every office has its own recycling bins for paper, newspapers, magazines and plastics, and the parliament claims that it now manages to recycle 60% of its waste.

But even with these plus points, the question still remains: how did Holyrood manage to score so highly in its BREEAM assessment, in spite of the high energy consumption? The answer is that it did so well only because it was assessed during the design stage – and that prompts doubts about the reliability and value of carrying out an assessment at that time.

The three main buildings in the complex were assessed using BREEAM for Offices (the MSP wing and Queensbury House to BREEAM 98, and the assembly building to BREEAM 2002). All three of them earned an Excellent rating, with the first two scoring 10/10, and the assembly building 9/10. One wonders whether the money spent on BREEAM might not have been more usefully invested in effective commissioning.

Overall, the building’s performance in terms of energy use is disappointing. But the parliament has a three-year target to reduce energy use in its buildings by 8% by 2009. Let’s hope this will mean more attention is focused on cutting energy consumption in future.

A closer look

The ventilation and heating solutions used at Holyrood are textbook examples of low-energy design in this type of mixed-use building. Displacement ventilation is used in the debating chamber, committee rooms and parts of the offices more than 5.5 m from the façade. In the debating chamber, air is introduced through grilles in the risers of the curved, banked seating. However, the ductwork is heavily attenuated in order to meet the tough acoustic standard –

NR25 – which was needed for TV broadcasts.

The air is supplied from one of 20 air handling units hidden in a huge double-height basement plantroom, and it returns to the units via a duct leading from close to the ceiling back to the floor of the chamber. This, too, has acoustic insulation to avoid perturbing the TV sound man.

The AHUs supply 100% fresh air, but this is pre-heated using thermal wheels for heat recovery from much of the air that leaves the building. The thermal wheels are reckoned to recover “at least 70%” of the heating energy, although there are no bypasses on the heat-recovery systems in the AHUs, which means that there is a fan-power penalty in summer.

The ventilation has variable-speed fans, controlled using CO2 sensors, and is designed to deliver up to 12 1/s/person, though this should ramp down when the parliament is not sitting or when only some of the MSPs are around.

All above-ground areas have opening windows for extra ventilation when occupants want it. Security was a concern, naturally, but restrictors, small window dimensions and a local intrusion detection system provided a way around this.

Turning to heating – critical for those fierce Scottish winters – there are two heating plant rooms in the basement. The total heating load is 2.4 MW, met by two condensing boilers, one standard high-efficiency unit (for use when the temperature of return water is too high for condensing), and one 150 kW combined heat and power unit.

All front-of-house areas are heated with either trench heating running along the perimeter or underfloor heating. The trench heating had programme implications because most the rooms are irregular, with curves everywhere, and many of the trench heaters had to be manufactured bespoke using timber cut-outs as templates.

The trench heaters run at 82°C to ensure they can deliver sufficient heat, while the underfloor heating circuits run at a maximum 50°C. The high temperature required for trench heating inevitably has implications for gas use, but presumably designers considered it was worth it to keep space heating out of sight.

The underfloor coils used for heating in winter switch to cooling mode in summer, and these, combined with airside cooling through the ventilation and chilled beams in the committee rooms, meet a total cooling load of 1.2 MW.

What the politicians think

In general, MSPs and their assistants seem fond of their office. All of the MSPs and their assistants asked about thermal comfort, air quality, lighting and noise said it was good or excellent in all respects.

David Hutchinson, an MSP assistant, says: “It’s a fantastic building. It’s a pleasure to work here.” Lighting in the MSP offices was described as “not harsh or bright”, and the only criticism was that the corridor lighting running along the side of the offices could not be controlled from inside the offices.

Linda Fabiani, an MSP, also enthuses about the building and the internal environment, scoring it very high on all criteria. She says some users were concerned that the lighting was a little dim in public areas, but she thinks this is trivial compared with the building’s successes.

Peter McCall, an MSP assistant, also thinks Holyrood offers a very good working environment, although he raises concerns about conditions in the MSP offices sometimes being cramped because many MSPs have more than one assistant. He also says that offices on the ground floor have insufficient daylight because of shading from the blast wall, and that halogen lighting in all MSP offices is left running 24/7.

Source

Building Sustainable Design

Postscript

Dr Jason Palmer is a director of Cambridge Architectural Research

Original print headline: "Power politics" (Building Services Journal, January 2007)