Despite being struck down by swine flu, our diariest explains the latest on mechanical ventilation and progress on site

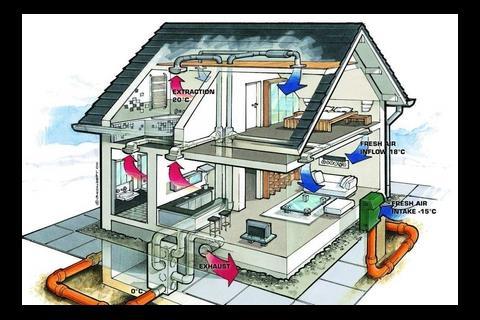

Mechancal ventilation with heat recovery (MVHR) is an absolutely integral component for achieving the necessary performance levels needed for Passivhaus buildings. It allows for sufficient and comfortable ventilation to all areas of the house whilst minimising the loss of heat gained from the sun, human activity, cooking, showering, electrical appliances and the like.

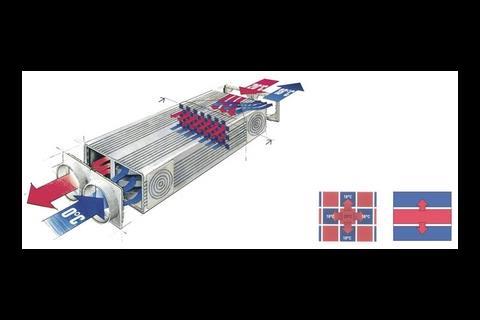

This is achieved by use of a sophisticated heat exchanger driven by two very efficient fans. The incoming air is blown past the outgoing air (though without being mixed together) so that heat is extracted from the outgoing air and is used to heat the incoming air. This has the effect of saving over 90% of the heat that, due to uncontrolled ventilation and draughts, would be lost in a more "conventional" house.

Essential for MVHR to run efficiently is the building’s airtightness. Passivhaus certification requires a building to have an airtightness of 0.6 air changes at 50 Pascals. Airtightness is tested by closing all apertures to the outside such as windows and ducting and having a fan fitted in an external door opening which lowers the air pressure within the building by 50 Pascals. This mimics a wind speed against the building of 20mph and is known as a "blower door test".

As a rule of thumb, MVHR starts to become economically and environmentally effective when airtightness levels are less than or equal to 3 air changes per hour @ 50 Pascals. When choosing MVHR units for Passivhaus buildings it is easier to use a model that has been tested by the Passivhaus Institut (PHI) as its efficiency levels can be put straight into the Passivhaus Planning Package (PHPP) - the software programme central to the design procedure. Units that have not been certified by the PHI get a 12% efficiency penalty over the manufacturers’ claims because of the greater stringency of the PHI test standards. This can have a dramatic and negative effect on the “magic” figure of 15kWh/m2/annum for space heating needs that Passivhaus buildings are aiming for.

A common misconception about MVHR systems is that one cannot open windows in a Passivhaus building. If the system is correctly set up it is less likely that the occupants would feel the need to open windows. However, occupants definitely can open windows, for instance to cool the building after a hot summer's day, or just to hear the birds sing on a spring morning.

Another essential factor for an efficient MVHR system is a correctly designed and installed ducting system, and I shall be talking about this and the installation of the system in the next blog.

On site

I have recently been laid low with suspected swine flu so have had to take a week off from management on site. My absence hasn’t seemed to have made much difference to the smooth running of things, which has been progressing well.

We are still waiting for delivery of the windows from Poland but, thanks to the building team’s ingenuity, we have managed to get on with completion of the first fix electrics, plumbing and MVHR ducting, laying the chipboard first floor, and building all internal stud walls.

The first floor ceiling is boarded and plastered, backing plaster applied to the block walls and airtightness taping has been fixed to the plywood window ‘boxes’.

An interesting development is Geoff and Kate’s request for us to use a clay plaster system on all internal block partitions. They came across this process in Austria when visiting Passivhaus homes there.

In theory the clay will allow the take up of excessive moisture in the air and release it in dryer conditions, although we don’t yet know how valuable this will be in a Passivhaus building with precisely controlled ventilation levels. However useful it is, it will look great, as it is self coloured and will be left unpainted.

4 Readers' comments