Hadlow college in Kent is the first educational building in Britain to meet the stringent demands of the German low-energy standard

In recent years the German low-energy Passivhaus standard has won plenty of admirers over here. In 2009, Y Foel, a three-bedroom family home in Wales, became the first UK development to be certified by the Passivhaus Institute. In the same year another Welsh building, Canolfan Hyddgen, became the first office to meet the standard. Now Britain’s first certified educational building has been completed in Tonbridge, Kent.

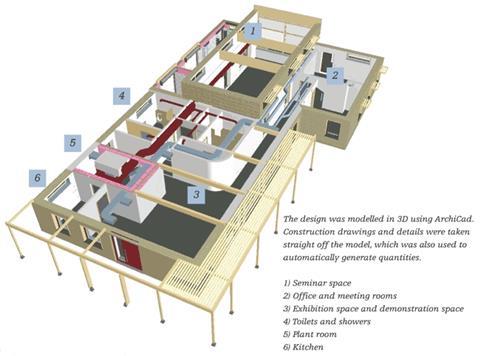

The teaching facility for Hadlow agriculture college is modest - only 345m2 with one large classroom, an exhibition space, offices and toilets - but it encapsulates the challenges that school designers face if they want to meet the standard.

Structures built to Passivhaus requirements need a well-insulated, airtight envelope that will cut energy use to a minimum. The easiest approach is to design a cube and make the north-facing windows tiny and the south-facing windows large, with external shutters. But the design at Hadlow college has not been driven exclusively by Passivhaus. James Anwyl, managing director of Sussex contractor Eurobuild, which designed and built the facility, says: “Rather than making it an engineering fetish I take it from an architectural and user perspective and push the design to make it comply with Passivhaus.”

So the building has a full-height, north-facing window that provides plenty of daylight to the main seminar room. This is a disaster when it comes to running the design through the Passivhaus planning package, which shows whether a project will make the grade. “I took the hit on it and made up for it elsewhere. As a result you’re not compromising it architecturally,” says Anwyl. This has meant designing in a lot of solar gain to the south and south-west elevations and from the skylights, using 400mm of insulation in the walls rather than the more usual 300mm and upping the insulation in the floor.

The building structure was erected and watertight in three days and was made airtight within 10. This is impressive when you consider that Passivhaus requires an airtightness of less than 0.6 air changes an hour - equivalent to the UK standard of 1m3/hr/m2.

This has been achieved by importing a factory-made closed timber panel system for the walls and roof from Austria. It is designed to be highly insulating - with the 400mm of insulation giving a U-value of 0.1W/m2K - and airtight. The panels were custom made and delivered with the larch cladding already attached.

With such a well insulated envelope, thermal bridging is a big issue. To reduce thermal bridges where the structure meets the floor, the panels sit on a ring of highly insulating aerated concrete blocks that were ordered for their thermal properties.

The primary airtightness barrier is the 10mm-thick orientated strand board that sheathes the inner face of the panels, while the joints between the panels are taped. This is a robust way of making the building airtight, says Anwyl, and it is less fiddly and time consuming than wrapping the entire building in a membrane.

The only place where a membrane has been used is on the underside of the roof panels to protect against condensation. Two airtightness tests revealed a leakage rate of 0.34 air changes per hour, more than 10 times better than the Building Regulations require.

One of the trickiest design issues was the ventilation. It needed to meet the requirements of Building Bulletin 101, which sets out guidelines for the minimum fresh air rates for teaching spaces - and balance this against the energy consumption of the fans. As is the norm on Passivhaus buildings, a mechanical ventilation system with heat recovery has been installed. Anwyl specified the most efficient system that is certified for Passivhaus use - a Drexel & Weiss Aero Centro unit. This runs from 8am to 6pm to provide background ventilation, but the teaching spaces have switches that allow the ventilation rate to be boosted to just above 8l/s/person when the room is full, to meet the requirements of Bulletin 101. “We couldn’t afford carbon dioxide sensors,” says Alwyn. “But it will be just like switching on the lights when teaching is taking place.”

Another potential problem is overheating. In a bid to even out internal temperatures, medium-density blockwork partition walls have been used, together with a slate floor to add some thermal mass to the lightweight structure. Usually the ventilation should be enough to carry away the heat gains from occupants and equipment. In summer, if the temperature in the seminar rooms rises above 22ºC, the clerestory windows open automatically between 7pm and 7am to give free night cooling - or until the temperature drops to 19ºC.

However, with up to 28 people in the seminar room at any one time, internal gains could become an issue and jeopardise the 120kWh/m2 a year threshold for primary energy demand. To prevent overheating, the Aero Centro unit has an integral heat exchanger connected to a 200m long ground loop. This can be used to provide pre-cooling if the air outside is above 21ºC - or pre-heating if it is below 3ºC - to the incoming air. If this isn’t enough there is also a ground-source heat pump installed that supplies underfloor heating and cooling. Anwyl estimates this will run for about a month in the winter and a month in summer.

So is this a model for schools of the future? Possibly. The building at Hadlow college has been modelled on the assumption that there will be little in the way of IT. “If each person came in with a laptop we’d have a problem from the heat gain because you are relying on the mechanical ventilation to provide the cooling and the underfloor system would have to come on, says Anwyl. In this case the danger is that the primary enery demand rises above the 120kWh/m2/year threshold.

Ventilation is also an issue when it comes to scaling things up for larger schools with more classrooms. At Hadlow, designing for extremely low noise levels necessitated the use of large-section ductwork, which is always difficult to accommodate especially when trying to limit and smooth turns and allow for insulation around all the supply pipes.

It’s not just a design issue - cost is a factor too. Anwyl believes one solution would be to use room-by-room ventilation systems that reduce the cost of ductwork and speed up installation. This is something he’ll be considering at length as he is now working on just such a scheme.

No comments yet