Today’s challenges demand different thinking. WSP’s executive managing director for property and buildings, Kamran Moazami, explores how the building industry can improve outcomes by bringing new ideas into projects

Designing and constructing buildings today is more complex than ever. Labour shortages, tighter regulations, supply chain disruptions and rising costs are amplifying these pressures. Despite this, companies are working together to create innovations to enhance project outcomes amidst volatile market conditions.

WSP’s executive managing director for property and buildings, Kamran Moazami, says, “These new solutions and approaches offer opportunities to complement and enhance traditional processes. Yet, while innovation is happening across the industry, it’s slow to embrace this change and is limiting its potential to progress – missing out on the benefits this provides.”

As highlighted in WSP’s newly published Expect Different playbook, there is an urgent need to pivot the industry’s mindset from a traditionalist-heavy approach to one that integrates new-age thinking. This article showcases the possibilities that exist when the industry works together, and why now is the time to act.

Four ways the industry can transform outcomes with contemporary tactics

To meet rising demand and address long-standing inefficiencies, the industry must embrace new methods and solutions like a kit-of-parts approach, digital-first fire stopping processes, CLT-Steel Composite Floor Systems and free cooling to overcome persistent issues.

Only when this shift happens, can the industry unlock scalable efficiencies, streamline resource use and enable faster, more stable project delivery without compromising design and quality.

1. Speeding up construction with a kit-of-parts approach

Currently, buildings are being designed as isolated, one-off projects – involving hundreds of thousands of decisions. This means when stakeholders move on to the next project, they spend valuable time making the same decisions again and lose key learnings that could be harnessed to enhance the delivery of subsequent buildings.

Traditional construction can also pose its own set of implications, involving numerous components being transported to site by trucks and built by thousands of people – which isn’t ideal given today’s labour shortages and the push toward net zero.

However, there’s a growing opportunity to adopt alternative methods, incorporating programmatic thinking and Design for Manufacture and Assembly (DfMA) to support faster project delivery, continuous optimisation of construction and improved sustainability.

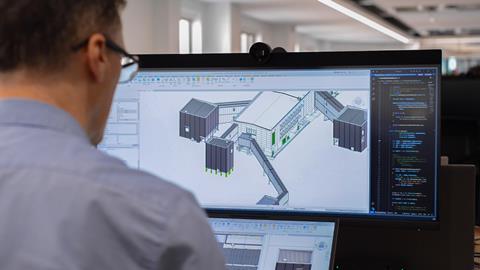

WSP has invented a new kit-of-parts approach that utilises this logic to enhance project outcomes, constantly refining multi-phased projects after the first one is completed.

This has already been implemented on 20 projects across aviation, rail, industrial, life sciences, defence, data centre and residential sectors – with notable clients like the Environment Agency and Manchester Airport benefitting from this.

2. Reducing carbon impact with material efficiency

There is huge potential for the UK to more heavily adopt mass timber construction to meet its net zero goals, which is already commonplace in countries like Sweden, Canada and New Zealand. The utilisation of best practices from these regions, particularly around fire safety in tall buildings, can help make this a more widely used approach across the UK.

WSP’s CLT-Steel Composite Floor System is an enhancement of this construction type, which was developed in collaboration with the Forestry Commission and the University of Warwick. It can deliver 50% greater strength and a 60% increase in stiffness, while being simple to build and low carbon.

3. Optimising energy consumption with free cooling

Countries like the UK, where outside temperatures are mild for most of the year, present the perfect conditions for passive design approaches like free cooling. This can be used to optimise energy consumption and reduce operational carbon.

WSP put this thinking to the test at its 70 Chancery Lane office, working closely with the landlord and project team to retrofit the building – eliminating gas and creating a low-carbon, future-ready workplace.

WSP’s specialists achieved this with an innovative mixed-mode, all-air Heating, Ventilation and Air Conditioning (HVAC) system, which utilises strategically integrated louvres and a Building Management System (BMS) to leverage the UK’s climate for free cooling for 80% of the year. This new system has resulted in the operational energy demand being reduced by 65%.

4. Better navigating building regulations with digital-first processes

The Building Safety Act 2022 has created greater complexity in relation to the construction of Higher-Risk Buildings (HRBs), often resulting in project delays and contractors taking on more risk.

Digital-first approaches offer a more effective way to navigate these challenges by embedding multidisciplinary insights into designs and consolidating project data to demonstrate compliance more efficiently at an earlier stage.

WSP, in collaboration with Mace and CLM Fireproofing, implemented a data-driven process to better manage passive fire stopping details and meet building regulation requirements.

This method, which was originally developed for Lansdowne House, has since been adapted and applied on five other WSP projects. It has helped provide project teams with clear visibility of any required design adjustments, enabling greater certainty around programme, cost and quality prior to construction.

Closing thoughts

The challenges facing the industry are complex but they’re not insurmountable. There is a story of hope as project teams work together to integrate new ways of problem solving. With the right mindset and tools, the sector can reshape its future – building better for people, planet and performance.

Interested in learning more about designing resilient projects for now and the future? Download WSP’s Expect Different playbook.

No comments yet