As the Chinese city of Guangzhou races to build a new district in time for the 2010 Asian Games, the designs of two British architects enter the spotlight. Thomas Lane charts the trials, tribulations and triumphs of Zaha Hadid’s opera house and Wilkinson Eyre’s West Tower

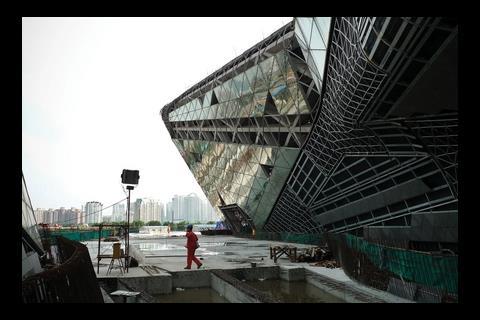

You can’t help wondering how it’s possible to deliver one of the world’s most sophisticated buildings while trying to keep your feet dry by balancing on a length of 4 x 2. But that’s how working life is in one part of the Chinese city of Guangzhou, where the monsoon rains flood building sites with tiresome regularity. The only way to beat them is to place lengths of wood around the place and it’s on these that workers balance as they go about their precarious business.

Add intense heat and humidity to the mix and you wonder how anything can get built.

In fact, Guangzhou is creating a whole new city district on the site of a former fishing village. This includes offices, residential schemes, hotels and cultural venues. It has come about because the city is expanding and needs more space and also because it is hosting the 2010 Asian Games, which means the race is on to get these buildings finished by the end of the year.

Height infatuation

Like Beijing with its exuberant Olympics venues, Guangzhou is going for some eye-catching buildings. These are positioned on a new axis linking the Pearl River to the existing city centre. At the end of this axis is the 610m-high television tower that will be the second tallest building in the world after the Burj Dubai. The infatuation with height continues with the tallest building ever designed by a British architect: Wilkinson Eyre’s 432m-high West Tower office building.

It bucks the Far Eastern trend for fiddly looking towers by being slim and elegant. The building, which has just topped out, has a luxury hotel on the top floors. Guests will be able to look down on a new museum designed by Hong Kong architect Rocco Design. This looks like a giant box hovering in the air – on closer inspection, the box turns out to be supported by a central concrete core.

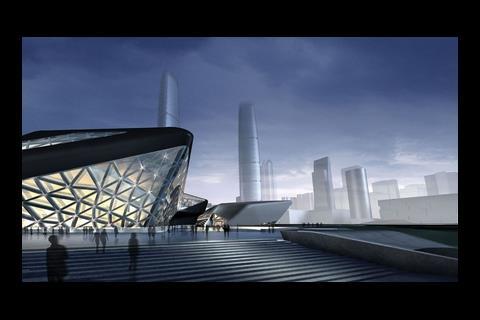

On the other side of this axis sits an opera house designed by another British architect: Zaha Hadid. This angular building has been particularly challenging to deliver and is Zaha Hadid’s first opera house – her competition-winning design for Cardiff was spat out by the locals and never built. The opera house looks like two angular stones washed up on the river bank.

Over the next few pages we take a look at how the Chinese are getting on with the construction of these two buildings designed by British architects.

“It’s the most complex thing I’ve done,” says Wen Kun Bo, the project director for contractor China State Construction of the opera house. “From the structural steel point of view it’s worse than the trouser leg project.” Zaha Hadid’s project architect on site, Simon Yu, who is translating, bursts out laughing. Apparently the trouser leg project is Wen’s very apt nickname for the Rem Koolhaus-designed CCTV building in Beijing. Wen wasn’t personally responsible for CCTV, but he knows all about it as it’s another China State Construction job.

The rain has stopped so it’s a good opportunity to see what Wen is building. The structure looks like a flattish chunk of rock broken off a larger boulder, with its sharp edges softened by years of weathering, and is very angular as a result. This freeform outer shell is made up of huge rectangular steel sections arranged as a triangulated structure. Inside, the angular shape and the oversized structure combine with the concrete auditorium that leans outwards in sympathy with the exterior shell to create a highly dramatic, dynamic effect.

Wen started work on the building in May 2006 and is meant to have it finished by the end of this year. It’s a tall order – opera houses are highly complex buildings as the auditorium acoustics have to be perfect. The shape has tested the design and construction team to the limit, and the programme has been knocked back by a fire in May.

Fee issues

Why make things so complicated? “The metaphor for this building is two pebbles picked up from the bed of the Pearl river and placed on the river bank,” explains Yu.

“We wanted to show this building as a dynamic entity; the pebbles are dragged from the river and have been formed and shaped by wind and water forces. This has a link with the immediate context, the Pearl river, but also the Buiyan mountains near Guangzhou.” The larger “pebble” includes a 1,800-seater auditorium; the smaller one houses a 400-seat multi-purpose space for theatre, conferences and exhibitions.

Unusually, Hadid has engaged a local firm of engineers to get the design to stand up. Arup was the engineer at competition stage but after Hadid won the job it went “all Chinese” because of what Yu describes as “fee issues”. It’s probably the most technically challenging building ever taken on by an all-Chinese team, as the structurally challenging buildings for the Beijing Olympics were all engineered by Arup.

Yu says it was a risk for the firm and that he was initially wary. “It wasn’t easy at the beginning but once the team got into the spirit of things, it went well,” he says. Huang Tai Yun is the engineer from the Pearl River Design Institute responsible for the structural design. “It was a typical architect-engineer relationship,” says Yu. “I would say ‘can you do this’ and they would go ‘whoa, hang on a minute!’ But it was never confrontational and was done in the spirit of the project.”

Huang has a calm demeanour, which is probably just as well. “It’s a nightmare for a structural engineer,” he says quietly. “The biggest challenge was the organic form of the building exterior. The design is anti-structure, as everything is leaning outwards or is cantilevered. The style overrides the basic principles of structural design, which is to keep things straight and regular.”

Various ideas for the building’s exterior structure were tried and rejected before the team settled on the triangulated structure. Initially Huang thought this could be made from a few large primary sections with smaller sections used as an infill but this was not going to be up to the job. He

says the building exterior doesn’t act as a shell-type structure because of its highly irregular nature. The only thing that enables it to stand up is very heavy duty steel sections joined by extremely rigid connections. Initially the structure was going to be freestanding but 14 support points have been added in the opera house and four in the smaller building. “This cut the amount of steel needed in half,” explains Huang.

The only way of ensuring the connections were strong enough to hold the structure together was to use cast steel. The opera house features 41 cast steel connections or “nodes”, which would be prohibitively expensive in Europe.

Three difficulties

The horseshoe-shaped auditorium in the middle of the building is constructed from in situ reinforced concrete. Like the exterior, the columns and walls are set at crazy angles, plus there are cantilevers up to 12m long. Huang says this works as a structural whole tied together with the floors, and the exterior rigid connections between the elements.

Unsurprisingly, Wen looks like he’s had a tough time building it. “There are three areas of difficulty,” he says. “The most difficult thing was positioning everything on site, the second was assembling the steel structure, and the third was the concrete, which was tricky because of the geometry and problems with the formwork. Apart from technical factors, the administration was also difficult in terms of project managing, because there were so many organisations to deal with.”

According to Yu up to 40 people could be present at site meetings.

The challenging nature of the building meant GPS positioning was too crude, so Wen has used lasers to set out the elements. “The margin of error with lasers is about one millimetre; with GPS it’s 5cm and we couldn’t afford that,” he explains.

Eight datum points were used as reference positions for the lasers. These helped position three cast steel nodes supported by scaffolding. The next stage was to join these using the rectangular steel box sections.

This was easier said than done. Virtually each face of the building had to be test assembled on the ground and adjusted before final positioning. “The expectation from the fabricator was that these would be adjusted onsite,” says Yu. The opera house exterior was erected in five stages and the smaller building in four.

The exterior structure is clad with a combination of glass and granite panels. The lower parts of the building are clad in triangular glass sections which correspond with the structure. Black granite with a flamed or rough-textured finish has been used on the upper parts of the building – this helps reinforce the idea of the pebble washed up on the bank. The granite panels act as a rainscreen. Standing seam roofing panels provide the waterproof layer on the horizontal areas, but an EDPM membrane has been used on the curved sections where the geometry changes direction.

On time and budget

Wen has also found the concrete challenging, partly because of its structural complexity and also because Zaha Hadid wanted a good finish to the concrete. “Fair-faced concrete is quite rare in China so getting the right formwork is quite difficult,” says Yu. In the end most of the formwork had to be imported or specially made.

When asked what effect the problems of getting the exterior steelwork right had on the timetable, Wen merely smiles and repeats a mantra familiar to any UK contractor. “We are on time and on budget,” he says. But Yu concedes the building is behind and may not be completed for May 2010, when Guangzhou hosts an arts festival.

The delays are not just down to the steelwork issues. On 9 May this year a section of the EDPM membrane caught fire. According to Yu, the fire was started by sloppy welding, and fortunately the damage is superficial. But the affected area has been cordoned off by investigators and Yu doesn’t know when this will be handed back.

Yu says the building will certainly open before November when the Asian Games are on. Whenever it does open, Guangzhou will have a building to rival the best in Beijing.

Plan of opera house

- 1 Entrance to opera house

- 2 Opera house foyer

- 3 Auditorium

- 4 Stage area

- 5 Back of house offices

Multi-Purpose space

- 6 Multi-purpose performance/seating space

- 7 Foyer

- 8 Back of house

A tricky acoustic number

The opera house must sound good during Western and Chinese operas. “It was challenging accommodating Chinese and Western opera as these two traditions are mutually exclusive,” explains Yu. “With Western opera the focus is on natural acoustics which takes precedence over the drama, whereas with Chinese opera it’s more about the dramatics with the audio relying on audio equipment. It sounds like strangling a cat but they love it.”

Unusually this opera house features an asymmetrical auditorium, an idea borrowed from the ill-fated Cardiff opera house. “From our experience in Cardiff we were convinced by the performance of asymmetrical auditoriums as it gives depth to natural acoustics,” explains Yu. He says there are three acoustic parameters: reverberation, sound pressure (volume) and clarity that need to be balanced.

Having worked out how to bounce the sound around the auditorium to optimise clarity, the team turned to the sound pressure which needed toning down at the front where it was too loud. The answer was to roughen up the hard surface to minimise reflections in the same way a matt surface reflects less light than a shiny one. Glass-reinforced gypsum panels will be used to clad the auditorium interior and these have been roughened up near the front of the auditorium. The roughening is done by moulding dips or cells into the panels; the deeper and the closer together they are, the greater the sound-deadening effect. As each panel is bespoke, a wax mould is used to cast each panel. This can be melted down and made into a new mould, which helps keep costs down.

Downloads

Southern end of the masterplan

Other, Size 0 kb

Postscript

Original print headlines: Crazy angles, soaring steel

No comments yet