The Grenfell Tower fire has led to calls for fire safety regulations to be examined. But this was not the first warning sign that the current rules are not fit for purpose. What can be done to make sure a tragedy on this scale doesn’t happen again?

In 2000 an all-parliamentary committee published a chillingly prescient report after an investigation into a fire at a block of flats where a pensioner died.

On 11 June 1999, a fire started on the fifth floor of Garnock Court, a 14-storey residential block at Irvine in Ayrshire. The building had been refurbished with new uPVC windows and polyester sheet cladding. The fire spread up to the 12th floor in minutes, breaking into other flats.

The report said that in future all external cladding systems should be either entirely non-combustible or be proven not to pose an unacceptable level of risk of fire spread. It added: “We do not believe it should take a serious fire in which many people are killed before all reasonable steps are taken towards minimising the risks.”

The awful tragedy two weeks ago at Grenfell Tower – where at the time of going to press 79 people were believed to have lost their lives in a fire caused by a fridge-freezer in one flat that ripped through the entire block – starkly revealed the failure to implement the recommendations of the report into the Garnock Court fire.

And this wasn’t even the only such warning.

A 2013 coroner’s report into the 2009 fire at Lakanal House in Camberwell, south London, where six people died, also recommended Part B (the building regulation covering fire) be reviewed, including the need for clearer guidance with regard to the spread of fire over the outside of buildings.

Rapid external fire spread isn’t a phenomenon confined to the UK: there have been several instances in Dubai including a fire at the Address Downtown hotel in Dubai on new year’s eve 2015. Earlier in 2015, there was a fire at the Marina Torch tower, also in Dubai, and the Lacrosse Tower in Melbourne – to name just a few. In each case, fire spread rapidly up the side of the building, with flaming material raining down on to the pavements below.

Aluminium Composite Material (ACM) panels have been cited as the cause of the rapid external spread of fire on the Dubai and Melbourne towers.

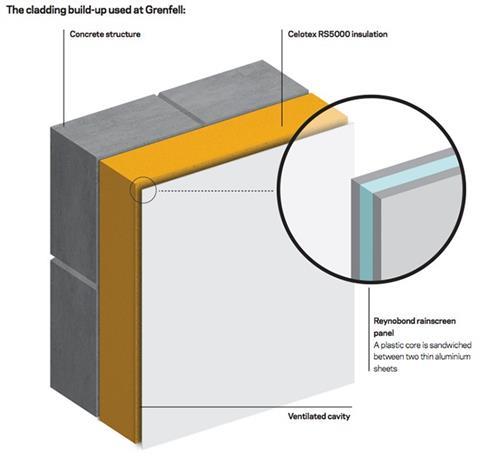

Film footage of Grenfell Tower shows flames shooting up the side of the building and thin sheets of burning cladding material falling to the ground. A product called Reynobond, an ACM panel, reportedly with a polyethylene core, was used for the external rainscreen on Grenfell Tower. This features a flammable, plastic core. Celotex RS5000, a polyisocynanurate or PIR insulation, was used to improve the thermal performance of Grenfell Tower and is also flammable (see “Focus on flammable cladding materials”, below).

Since the fire, the communities department has ordered local authorities to submit cladding samples from other buildings deemed to be at risk for fire testing. It is not clear exactly what tests are being undertaken, but at the time of going to press, 95 tower blocks have failed these tests (see Testing Times box on page 23). A key part of the official fire investigation will be to establish the contribution each cladding element made to the spread of the fire. This will feed into the public inquiry into the fire which will also investigate why combustible cladding has been used on so many buildings.

The initial findings of the investigation may not be known for months, and in the meantime there is understandable public outcry at how a fire like Grenfell Tower could happen in 21st-century Britain. How could a residential tower housing around 600 people pass all the system checks and then go up in flames?

Unfortunately, the background to this disaster is difficult for the public and even construction professionals to navigate. This is because of the many confusing definitions of limited combustibility within England’s building regulations; the range of testing regimes that exist for building products; the fragmented nature of building control services; and the perennial spectre of poor-quality workmanship that could exist on any project.

This has led some experts since the fire to call for a change in legislation to create a simplified approach whereby it becomes a requirement that all cladding systems be constructed using non-combustible materials. Here, we try to untangle the systemic failures that apparently allowed so many buildings with combustible cladding to comply with current regulations and consider what the implications could be for cladding systems containing flammable materials in the future.

Fire compliance

A few days after the fire (on Sunday 18 June) chancellor Philip Hammond said he understood the flammable cladding used on Grenfell Tower was banned. The Department for Communities and Local Government has also said the polyethylene-cored panels did not pass building regulations for buildings over 18m tall.

But in questions from MPs after a statement to the House of Commons on 22 June, Theresa May said she could not yet say whether the cladding used on Grenfell Tower complied with relevant fire and building regulations. The contractor on the 2014-16 Grenfell refurbishment, Rydon Maintenance, has said the building met all building regulations and cladding contractor Harley Facades has said aluminium composite panels are a commonly used product in the refurbishment industry. A leading industry expert has looked at the drawings submitted as part of the planning application to Kensington and Chelsea council for the refurbishment works to Grenfell Tower and has told Building he thinks the cladding does comply with building regulations.

He said: “The specification I saw on the planning documents does look like it complies although there are a whole load of qualifications to that.” He said the test data used to justify building regulations compliance was “very complicated”. So how is it possible that combustible cladding can comply with fire regulations? The answer seems to be in the complexity of the different routes to compliance that can bamboozle contractors and building control inspectors alike.

A principal objective of Part B of the building regulations is to contain a fire within one area for as long as possible to enable people to escape and give the fire service time to extinguish the fire. In tall residential buildings, front doors, separating walls and floors, and external cladding should be fire-resistant to prevent vertical and horizontal fire spread.

The specification I saw on the planning documents does look like it complies although there are a whole load of qualifications to that

Industry source

The requirement for external walls in Part B is clear: “The external walls of the building shall resist the spread of fire over the walls and from one building to another, having regard to the height, use and position of the building.”

This appears to be a fairly straightforward requirement, but complexities and ambiguities begin to creep in because there are four different routes to meet the requirement:

■ The first is the prescriptive guidance contained in Part B which details the fire performance required for the different elements making up a cladding system. This is summarised in three paragraphs. The first covers external surface fire performance, the second “insulation and filler materials” and the third contains guidance on cavity barriers.

According to this guidance, the external surface fire performance of the Reynobond panel is acceptable for buildings over 18m tall. The requirement for insulation and filler material performance is that it must be of “limited combustibility”. An appendix defines what is meant by limited combustibility; insulation and filler materials where tested to a European standard must have an A rating. Both variants of the Reynobond ACM panels have a B rating and therefore don’t meet this requirement.

But Stephen Ledbetter, a consultant and former director of the Centre for Window and Cladding Technology, doesn’t think the section on insulation and filler materials is clear. “The term ‘filler’ is not clearly expressed,” he says. “People haven’t thought of a polyethylene core in a cladding panel as a filler and that it should be non-combustible.” He adds that concerns over the limited nature of the tests for non-combustibility, with its focus on the surface spread of flame, was the reason why the second route to compliance was introduced in 2004.

■ This second route to compliance is based around a full scale test to BS 8414 which is described in the BRE publication BR135, “external thermal insulation for walls of multi-storey buildings”. The insulation used on Grenfell Tower was Celotex RS5000, a PIR product which does not meet the limited combustibility requirements set out in the prescriptive guidance in Part B. But Celotex RS5000 complies when incorporated into a cladding system that has been tested to BS 8414. The cladding system used for this test is very similar to the build-up used on Grenfell Tower. A key difference is that the test cladding panel is a non-combustible fibre cement product. This arrangement is compliant with Part B and would be acceptable to building control.

Despite this, on 23 June Celotex removed RS5000 from sale for use on buildings over 18m tall.

Manufacturer Arconic has also announced it is discontinuing global sales of Reynobond PE for use in high-rise applications. In a statement, it said: “This is the right decision because of the inconsistency of building codes across the world and issues that have arisen in the wake of the Grenfell Tower tragedy regarding code compliance of cladding systems in the context of buildings’ overall designs.”

■ There are two other routes to compliance if test data on a cladding build-up to BR135 is not available. One is that a desk-top study can be performed to convince building control this would comply with Part B. This can be performed by a suitably qualified fire specialist who takes data from other fire tests to demonstrate the solution being submitted for approval would meet BR135. This “desk-top” approach means combistible materials can be signed off without the need for any further tests.

■ The final option is to employ a fire engineer who takes a holistic view of the building design and applies fire protection and mitigation strategies in high-risk areas but minimises these in areas of low risk. For example, the guidance in Part B requires structural steel to be fire protected. A fire engineer will model the building to demonstrate fire protection might not be needed in low-risk areas but should be beefed up in high-risk areas.

This approach tends to be used on complex, high-value projects and is unlikely to be used to model local authority refurbishment projects.

Role of building control

The justification for using a specific cladding on any building system, whether it contains combustible material or not, needs to be assessed for compliance with Part B by a building control body, either local authority building control or private approved inspectors.

Unfortunately, the time spent assessing applications, the expertise and checking regime can vary between individual local authority building control departments and also between private approved inspectors.

You can submit an application in Manchester and get a very different response from, say, Birmingham, where there are different fire experts and a different fire authority

Steve Cooper, Cundall

Steve Cooper, who heads the fire engineering division of engineer Cundall, says the level of expertise within building control divisions varies. “Some work on a whole range of building types and have a wider range of expertise than others,” he says. Cooper says the approach to compliance varies significantly.

“You can submit an application in Manchester and get a very different response from, say, Birmingham, where there are different fire experts and a different fire authority,” he says.

“It can even vary between officers in the same local authority.”

Like all public-sector departments, building control has come under cost pressure. This is exacerbated by the need for local authority building control departments to compete for business with approved inspectors, which after all was the reason for introducing competition into the building inspection regime in the first place.

There are also cost tensions from having to compete with approved inspectors for jobs. Cost pressures could affect the level of scrutiny building control applications are subjected to.

Paul Everall, chief executive of LABC, the body that represents local authority building control departments in England and Wales, concedes budgets are tight. “Financial pressures on local authorities have been in existence for several years and it’s difficult for our members to develop a comprehensive service. There are less people in local authority building control than there were some time ago.”

This means less time to scrutinise building control applications. It also means less time for on-site inspections to make sure the materials in the specification aren’t substituted for cheaper products on site and to check workmanship. There is no suggestion that cheaper products were substituted on Grenfell Tower or that workmanship wasn’t up to standard.

Cavity barriers

The correct installation of cavity barriers as part of the cladding system is crucial to stop fire spreading within cavities and the investigation into Grenfell is bound to look at whether these were installed correctly in the tower. There have been big problems with cavity barriers being incorrectly installed or even missing from multi-storey timber-framed buildings. Fires can break out, spread into the cavity and spread uncontrolled up through the building. The industry has since largely switched to the use of cross-laminated timber which, among many other advantages, has better fire performance.

Jim Glockling, technical director of the Fire Protection Association (FPA) – the UK’s national fire safety organisation that advises the insurance industry on risk – thinks tests such as BR135 are conducted in perfect conditions with properly installed cavity barriers.

There are no allowances for changes to buildings such as a workman drilling a hole through the cladding to put in a plastic drainage pipe or vent then failing to fire stop the penetration afterwards.

“There are mistakes and inaccuracies that come into installation and over time the building gets damaged,” he says. “If you start with non-combustible materials these are much more forgiving.”

The FPA is about to start a series of “sensitivity tests” to determine how different cladding systems perform when subjected to real-world conditions such as a hole being drilled into these. “What we want to determine are the deviations from perfection,” he says. The results of these tests will be fed back to the insurance industry.

Glockling thinks there is a strong case for legislating in favour of non-combustible materials in cladding systems. “There needs to be a long, hard look at this,” he says. “People need to realise there are large commercial fires every week. We feel it’s unacceptable and there must be life safety implications.”

Other countries have already legislated in favour of non-combustible cladding systems. Dubai recently changed its regulations so only non-combustible materials can be used. It has gone one step further requiring regular maintenance of cladding systems and replacement after a certain date. A building damaged by fire must have all cladding panels replaced by non-combustible ones. Australia now requires the materials used in external walls, including cladding, to be non-combustible. And Scotland, which has devolved building regulations, requires all cladding materials in high rise buildings to be non-combustible or meet stringent fire tests. It took on board the findings of the inquiry into the Garnock Court fire and changed its fire regulations as long ago as 2005. The pressure on the government to change regulations in England is now overwhelming, but for the residents of Grenfell Tower, it is a case of too little, too late.

Focus on flammable cladding materials

Why use flammable materials in cladding systems in the first place? Many insulation products are polymer (plastic) based, whereas non-combustible products are based on mineral wool.

High performance polymer-based products offer better thermal performance for a given thickness, are lighter and less affected by moisture penetration compared with mineral wool.

This has made polymer-based insulation an attractive option for use in external cladding systems with a rainscreen.

The rainscreen keeps the weather off the insulation and provides the decorative finish to the building. It can be made from a range of materials and is separated from the insulation by a narrow cavity. Aluminium composite panels, also known as ACM panels, are popular because these are attractive, available in a selection of colours, are lightweight and cheap.

Costs are kept down by using a thin aluminium external facing and a cheaper core material which gives the panel rigidity. At the time the refurbishment of Grenfell tower was being carried out in 2016 two variants of Reynobond were available: polyethylene cored and a more fire resistant version with a thermoplastic core. It has been reported that the cheaper PE variant was used at Grenfell Tower.

Testing times

The government has introduced a test regime to establish how many other local authority residential towers have been refurbished with flammable cladding. At the time of going to press 95 towers had been tested with a 100% failure rate and a further 500 or so still need to be tested. This suggests either that failure to comply with building regulations is rife or that the government test differs from the tests used to define fire performance in Part B.

The tests are being carried out by BRE on behalf of the communities department. Building contacted BRE and the communities department for details of the test but neither organisation had provided details by the time Building went to press.

In a statement to the house on 26 June, communities secretary Sajid Javid said the BRE test had three categories and cladding material in category 2 or 3 did not meet the requirements for limited combustibility in the building regulations.

The 100% failure rate of the samples submitted for testing has led some experts to question whether the test differs from those used to define fire performance in Part B. These tests apply a flame to the surface of the product being tested. If the panel has a non-combustible metal facing over a plastic core, it will perform better than a flame being applied to an exposed edge.

“We are having to assume BRE are applying the test to the edge of the panel and are getting a different result [from the tests used to define limited combustibility in the building regulations],” says Stephen Ledbetter, a consultant and former director of the Centre for Window and Cladding Technology. “It has been suggested to me that BRE are stripping off the aluminium facing and applying the test to the polyethylene core.”

No comments yet