We’ve all heard the mantra: ‘Reduce, Reuse, Recycle’, but should we be doing more?

There’s been a good focus in the construction and property sector on avoiding sending waste to landfill over the past few years. Many construction businesses, including the one I work for, have been steadily improving their recycling rates, or at the very least not sending waste to landfill. But while we can all pat ourselves on the back for a job well done, there is a wider problem: the industry still creates far too much waste.

Part of the challenge is in the way buildings are designed and procured. As a contractor we are often faced with the problem of trying to manage the waste that was not designed out, but has instead been designed in.

Often buildings are not designed to last that long, or as long as they should and could do, and they’re made from materials that can make it hard or impossible to reuse or recycle at the end of life. It’s not necessarily the fault of the designers, it’s just how current business models manifest themselves.

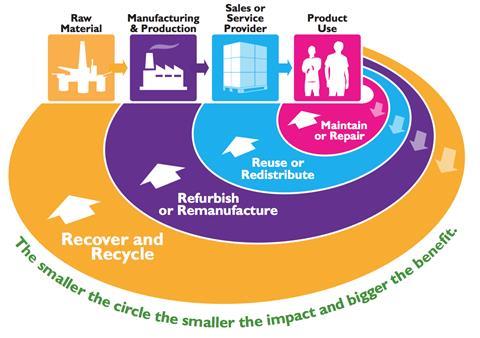

Like many other industries, most of the property and construction industry’s work is predicated by the linear “take - make - waste” business model. That is, raw materials are taken (extracted out of the ground or taken from the natural environment), manufactured or made into a product, distributed and used and then finally disposed of as waste at the end of their life.

With commodity prices almost tripling in the past decade, reflecting the diminishing availability of easily accessible resources and energy, it is becoming a model that is increasingly unsustainable.

This is why smart businesses are increasingly embracing the concept of the circular economy. It is a model propagated by organisations like the Waste and Resources Action Programme (WRAP) and The Ellen MacArthur Foundation. The circular economy takes its cue from living systems, by relying on renewable sources of energy, keeping hold of and using resources for as long as possible, minimising the use of any harmful substances, eliminating waste by good design and ensuring recovery of materials at the end of life to be regenerated into new products.

Although the term “circular economy” may not be that familiar to everyone, it’s actually not a new concept.

Smart businesses are increasingly embracing the concept of the circular economy. It is a model propagated by organisations like the Waste and Resources Action Programme (WRAP) and The Ellen MacArthur Foundation

For example, the aircraft industry has been offering “power by the hour” and similar programmes for their engine supply since the sixties, so if you operate an aircraft, you don’t need to buy the engines, you buy “flying hours” instead. The engine manufacturers retain control of the valuable raw materials and resources throughout the life cycle, and they create more value for their business as they’re no longer just selling a product, they’re selling a complete service instead.

In the built environment sector, sustainability pioneer Interface has been leasing rather than selling floor coverings for nearly 20 years. The thinking behind this is that most people don’t need to own a carpet, they just need the use of one.

At Mace, we’ve recently been trialling desks made from engineered, recycled cardboard which can be folded up and returned to the supplier for reuse or remanufacturing when they are no longer needed. The problem of unwanted desks once a project has completed is common in the construction industry, and this will help to avoid it.

However, these are still fairly rare examples. There are still frequent practical difficulties to overcome, for example:

- Who will accept liability for a reused steel beam?

- Will clients and end users accept perceived “second hand” instead of brand new materials?

- Is the supply industry geared up to provide such services, and is anyone demanding them?

It’s an issue I’ve been discussing recently with several of my peers in the UK Contractors Group (UKCG), by taking part in an engaging workshop organised by Forum for the Future.

We identified that shifting from the “take - make - waste” model to the circular economy model can be challenging, requiring buy in from all parties. But one practical step that we can all take immediately is to engage our colleagues and peers to debate and create a dialogue around what we can do.

To help promote the concept of the circular economy, the UKCG materials task group have recently developed and launched a poster/infographic, which is available to download here:

Andrew Kinsey is an operations director and head of sustainability for construction at Mace

Downloads

UKCG Circular Economy

PDF, Size 0 kb

1 Readers' comment